Mounting structure of control disc seat of washing machine and washing machine

A technology for controlling a panel seat and an installation structure, which is applied in the field of washing machines, can solve the problems of low production efficiency, increased product cost, labor-hour consumption, etc., and achieves the effects of high installation efficiency, saving manufacturing cost, and improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

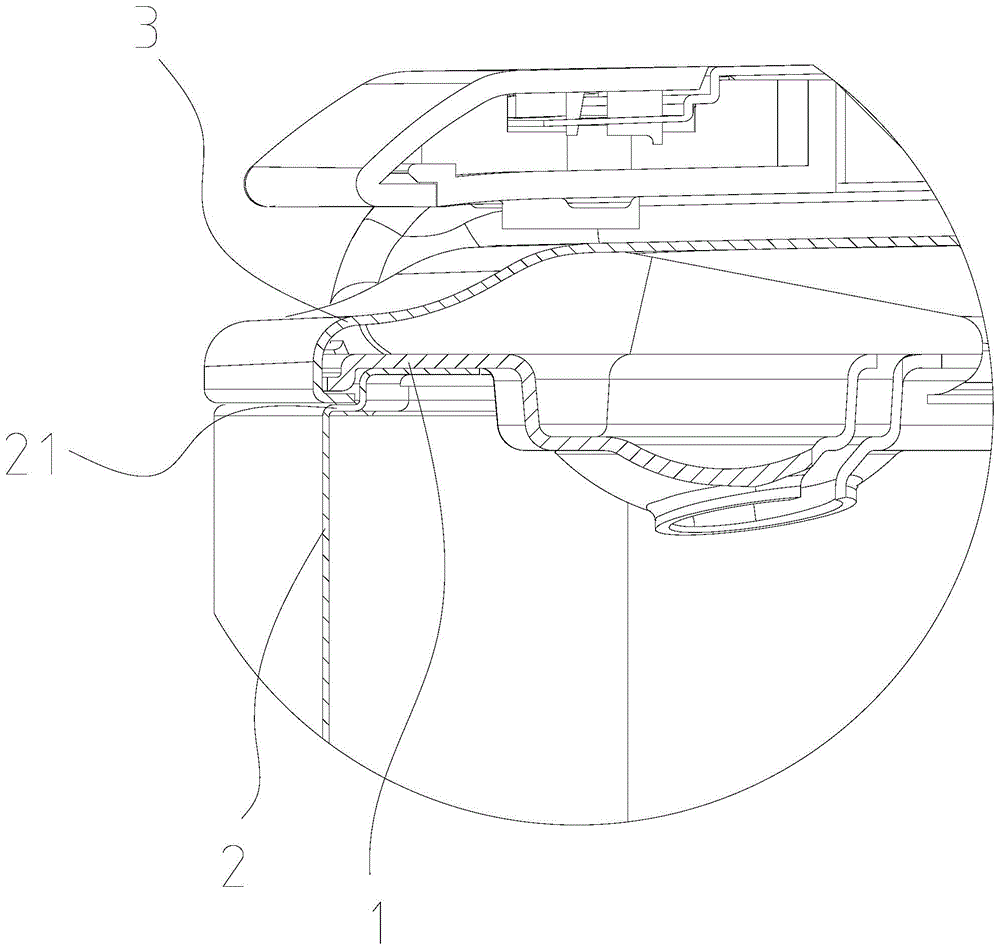

[0030] The preferred embodiment discloses an installation structure of a washing machine control panel seat. The installation structure of the washing machine control panel base includes a first mounting plate 1, a second mounting plate 2, a third mounting plate 5, and a control panel base 3, and the control panel base 3 is fixed on the washing machine casing through different mounting plates, thereby Restrict its degrees of freedom in all directions.

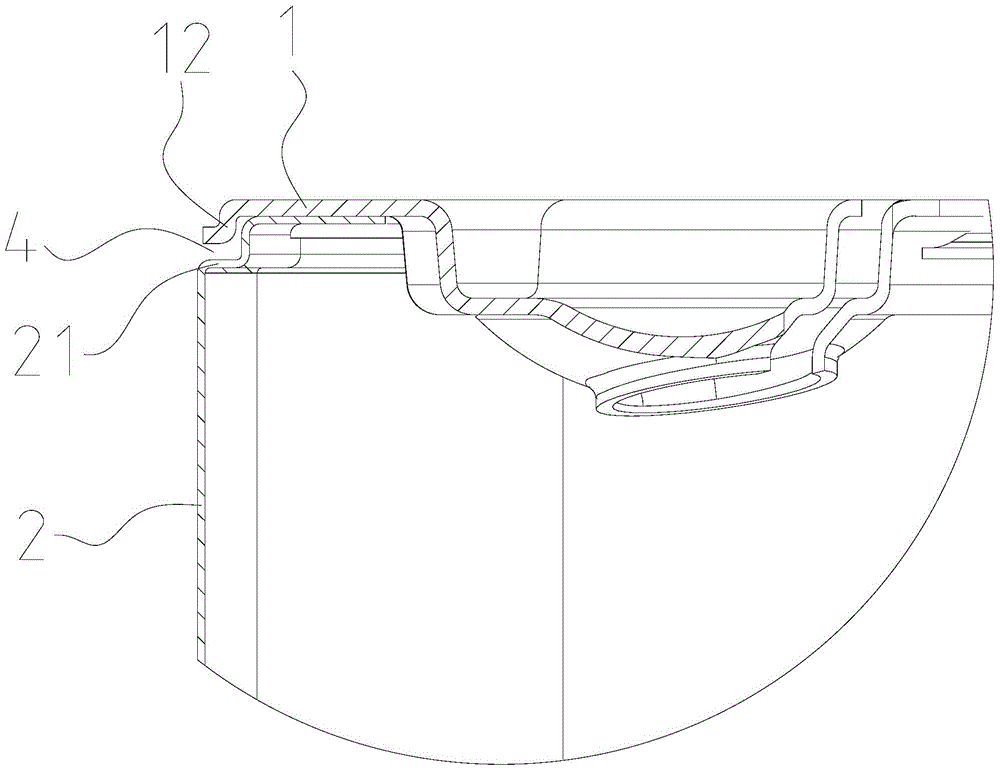

[0031] like figure 2 and image 3 As shown, the first mounting plate 1 and the second mounting plate 2 can form an accommodation space 4, and the flange at the front of the control panel base 3 is snapped into the accommodation space 4 to limit the movement of the control panel base 3 up and down. The accommodation space 4 It can be a cavity with two sides open or a card slot with one side closed.

[0032] The first mounting plate 1 (such as Figure 4 (shown) includes a board main body 11, a first matching portion 12 exten...

Embodiment 2

[0038] This preferred embodiment discloses a washing machine control panel mounting structure, the structure of which is basically the same as the first preferred embodiment. The installation structure of the control panel seat of the washing machine includes a first installation plate, a second installation plate, and a control panel seat, wherein the first installation plate and the second installation plate can form an accommodation space, and the flange of the control panel seat is snapped into the accommodation space , used to limit the control panel seat.

[0039] The difference is that: the first matching part is not limited to be an arc part, but can also be a right-angle structure, a plate-like structure, or other structures, which can meet the needs of forming a receiving space with the second matching part; the third mounting plate can be an angle The plate can also be a structure of other shapes, such as a rectangular plate, which can be connected with the control ...

Embodiment 3

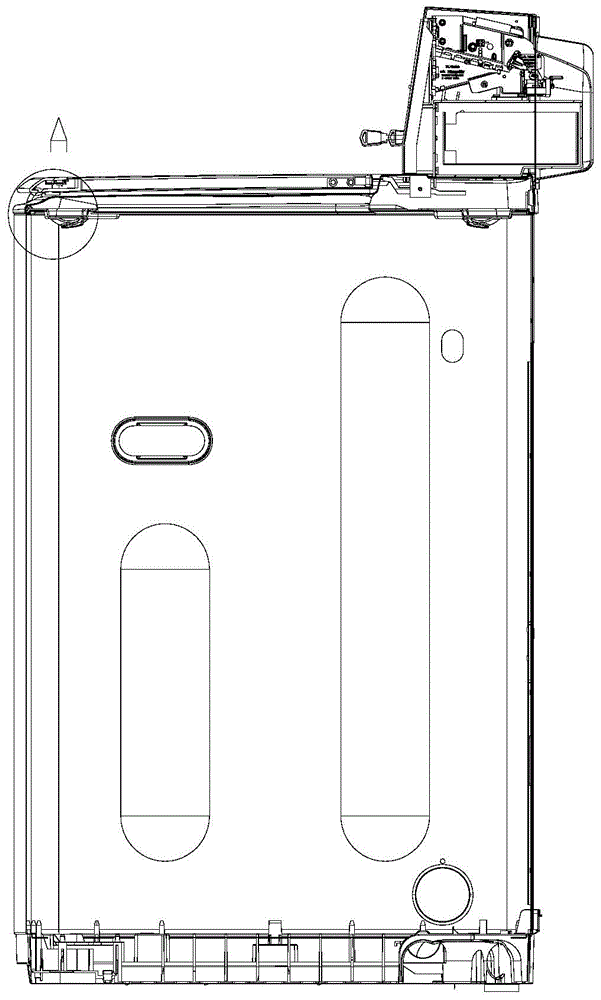

[0041] This preferred embodiment provides a washing machine, such as figure 1 As shown, it includes the installation structure of the control panel base as described in the preferred embodiment 1 or 2. The second mounting plate is the front plate of the washing machine cabinet, and the two first mounting plates (front angle plates) are respectively welded to the two ends of the front part of the washing machine cabinet, and the plate-shaped structure protruding from the front plate of the washing machine cabinet is connected to the first The first mating part of a mounting plate forms an accommodation space, and the flange at the front of the control panel seat snaps into the accommodation space; two third installation plates (rear angle plates) are welded to both ends of the rear of the washing machine cabinet, and the control panel The seat rear is connected with the third mounting plate by screws.

[0042] The four corners of the washing machine can also be provided with f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com