Modularization wall body with self-bring decoration and installation method thereof

An installation method and modular technology, applied in the direction of wall, building material processing, building components, etc., can solve the problem of complex module production process, and achieve the effect of good decoration effect, strong operability and simple installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

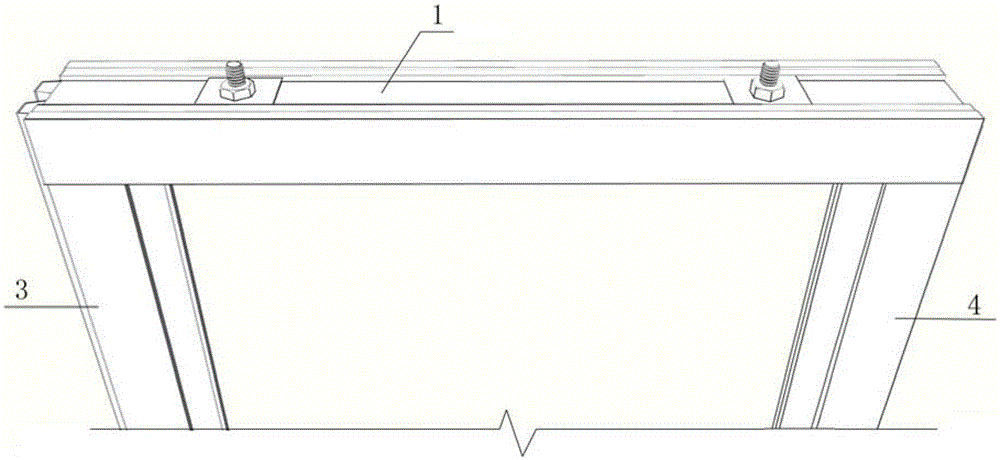

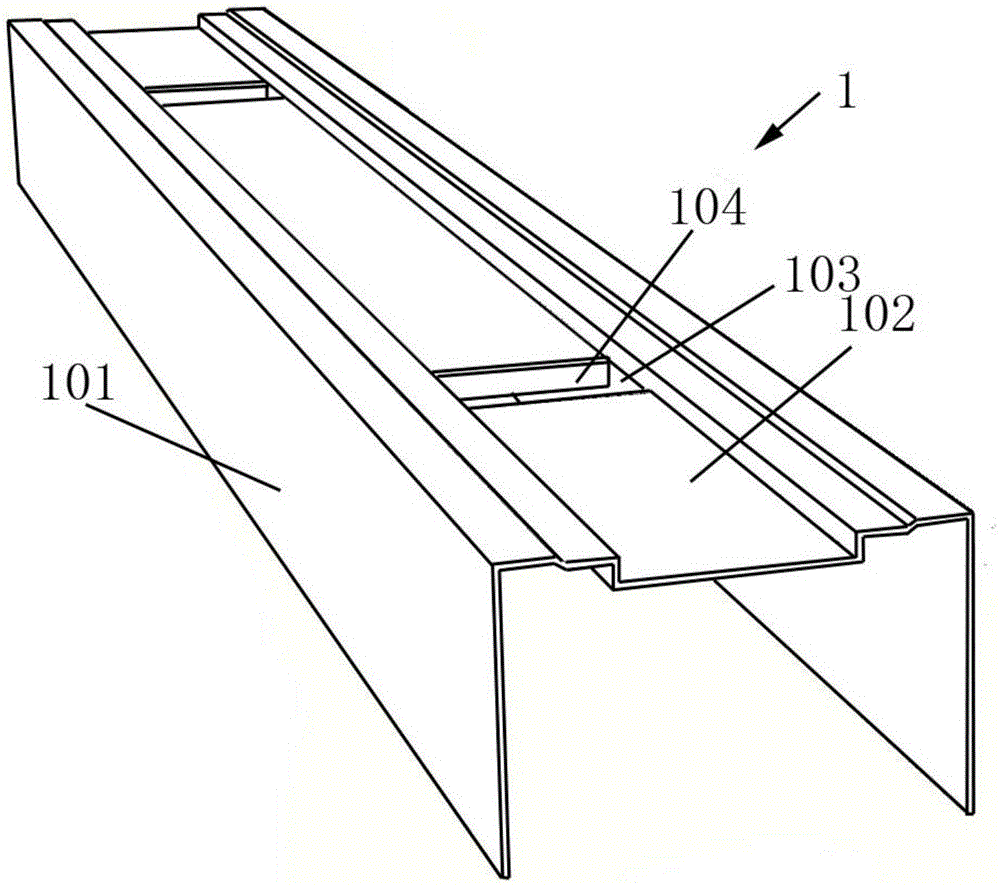

[0040] A modular wall with its own decoration see Figure 1 to Figure 9 , including rectangular wall skeleton, gypsum board layer and finish layer.

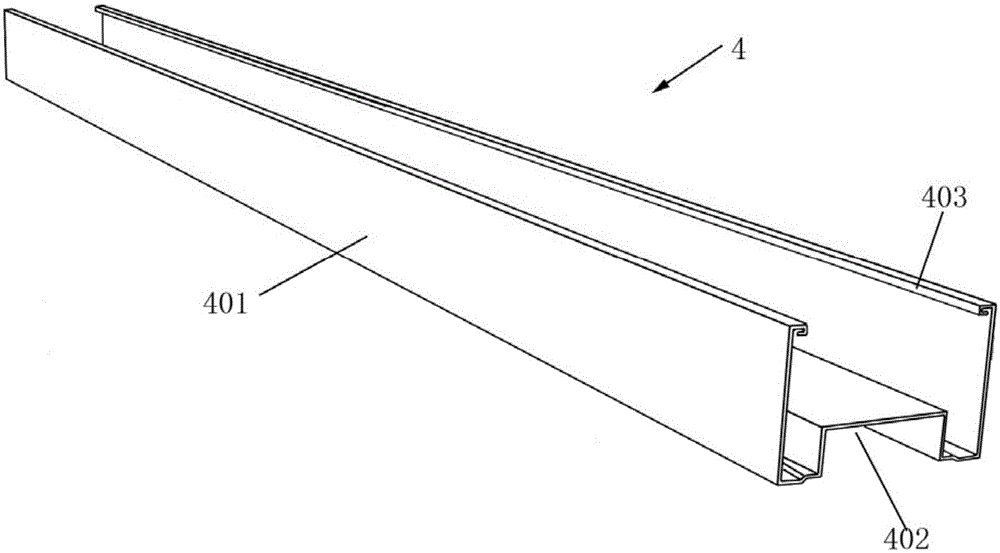

[0041] Among them, the rectangular wall skeleton includes the sky keel 1, the ground keel 2, the left vertical keel 3 and the right vertical keel 4, such as figure 1 As shown, the ground keel 2 has the same structure as the sky keel 1, and the placement direction is just opposite, which is not shown in this figure due to the limitation of space and view orientation.

[0042] A modular wall with self-decoration also includes an outer finish 5, an outer gypsum board 6, an inner gypsum board 7, and an interior finish 8 attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com