Oil production structure capable of achieving multi-oil-layer commingled production

A technology of multiple oil layers and production pipes, which is applied in the fields of fluid production, earthwork drilling, drilling equipment, etc., can solve the problems of insignificant economic benefits of single multi-layer oil well production, inability to achieve co-production with existing production processes, and complicated processes. Achieve the effect of improving mining efficiency, simplifying complex processes and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the drawings and examples:

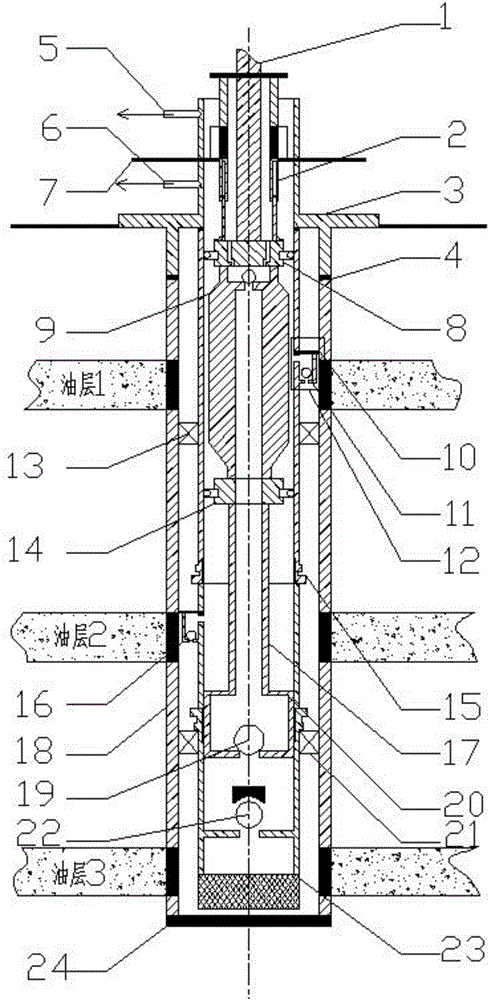

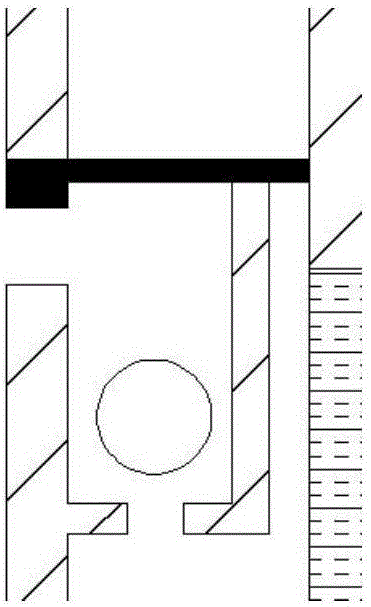

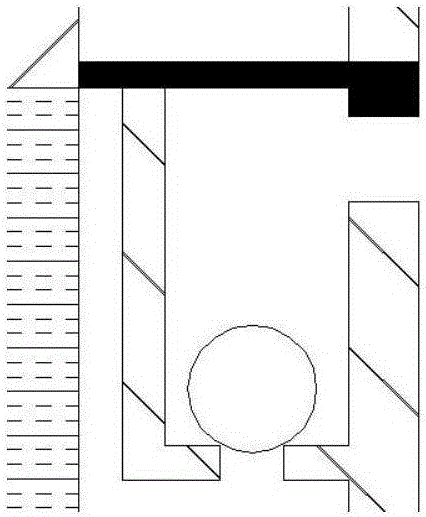

[0024] Such as figure 1 As shown, a multi-layered oil production structure includes polished rod (1), plunger-type annular partition (2), casing head (3), threaded sealing ring (4), and upper liquid outlet (5) , The lower liquid outlet (6), the oil-gas partition (7), the flow centralizer (8), the convex annular tube (9), the sealing ring (10), the valve ball (11), the upper side valve (12) ), upper packer (13), hollow centralizer (14), tubing (15), lower side valve (16), hollow sucker rod (17), casing (18), swimming valve (19) , The pump barrel (20), the lower packer (21), the fixed valve (22), the screen (23), the bottom of the well (24), the polished rod (1) passes through the flow centralizer (8) and The convex annulus (9) is connected, the polished rod (1) is connected to the ground device to transmit power, the upper liquid outlet (5), the lower liquid outlet (6), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com