Drainage device for tunnel pavement water seepage and construction process

A technology of drainage device and construction process, applied in water supply devices, drainage, tunnels, etc., can solve problems such as tunnel operation safety, and achieve the effects of eliminating water flow, low cost and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

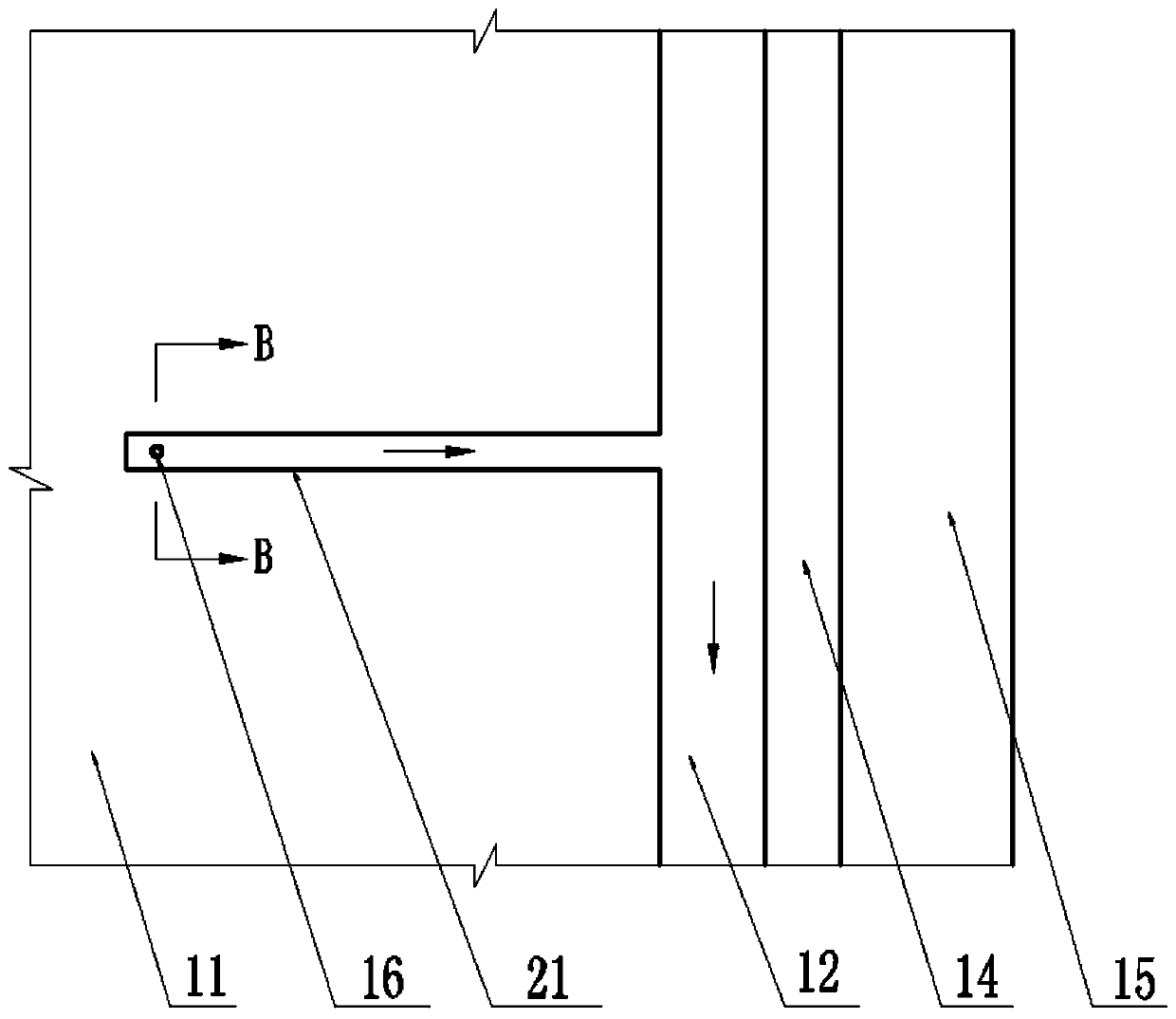

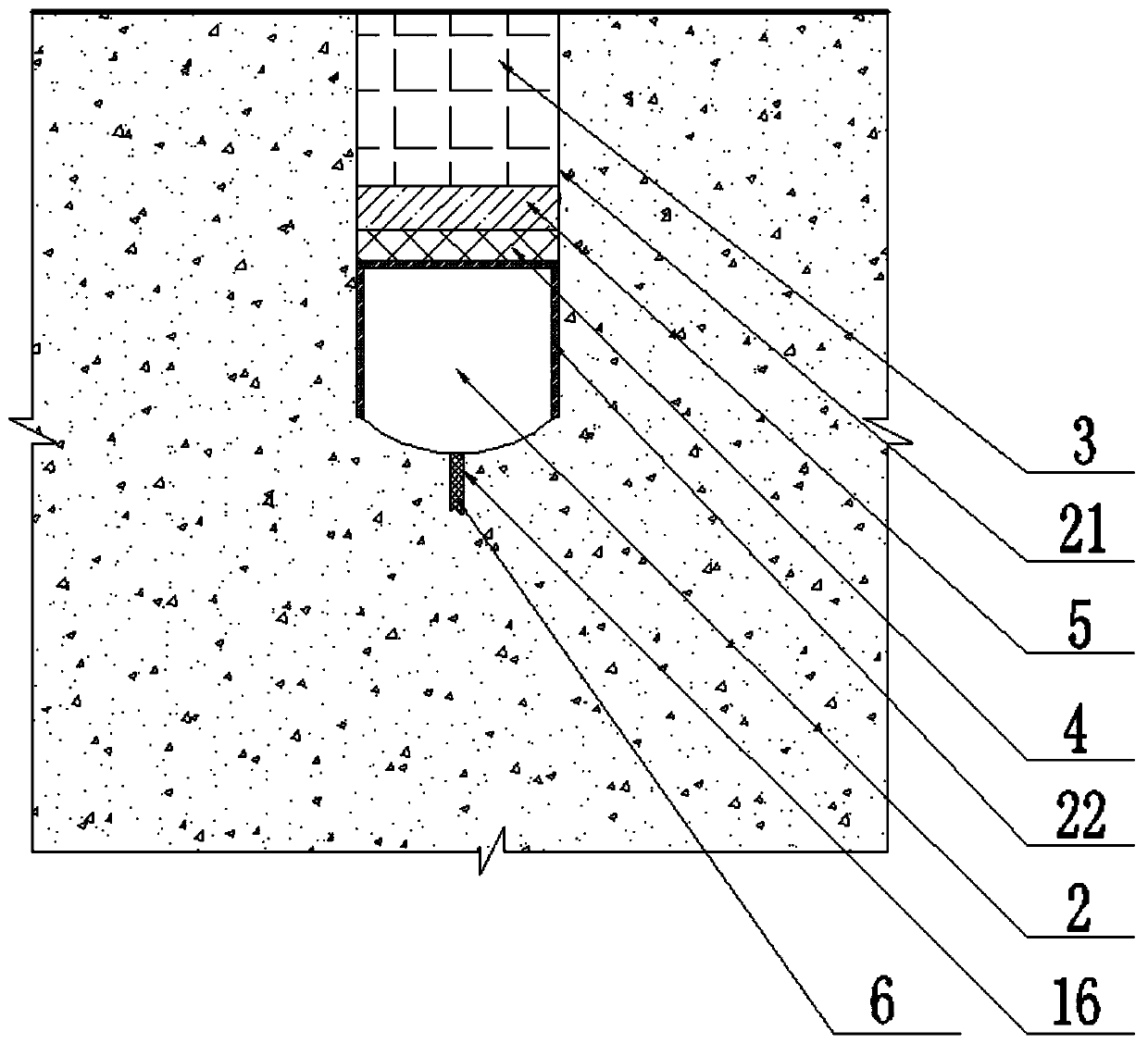

[0032] Such as figure 1 with figure 2 As shown, the drainage device for water seepage on the tunnel road surface of the present invention includes a tunnel, and also includes a drainage channel 2 provided on the road surface 11 with seepage holes 16 and communicated with the drainage ditch 12. The drainage channel 2 is embedded in the Inside the road surface 11 ; the top of the drainage channel 2 is provided with a filler layer 3 , and the top of the filler layer 3 is flush with the road surface 11 . The drainage channel 2 includes a drainage groove 21 and a U-shaped cover plate 22 arranged in the drainage groove 21 and matching the width of the drainage groove 21. The cover plate 22 is arranged opposite to the drainage groove 21, and the drainage groove 21 and the cover plate 22 surrounds and forms the drainage channel 2. The bottom of the drainage groove 21 is arc-shaped. The filler layer 3 is high-strength polyurethane elastic concrete. The water seepage hole 16 is pro...

Embodiment 2

[0035] Such as figure 2 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. A waterproof layer is also provided between the drainage channel 2 and the filler layer 3; the waterproof layer includes a cement-based permeable crystalline waterproof coating layer 4 and the SR rubber caulking paste layer 5, the drainage channel 2 is connected to the filler layer 3 through the cement-based permeable crystalline waterproof coating layer 4 and the SR rubber caulking paste layer 5 in sequence.

[0036] Working principle: the thickness of the cement-based infiltration crystalline waterproof coating layer 4 is 10mm; the thickness of the SR rubber caulking paste layer 5 is 10mm; the present invention adopts double waterproofing measures of the cement-based infiltration crystalline waterproof coating layer and the SR rubber caulking paste layer The bottom can effectively prevent the water flow on both sides of the waterproof layer in the drainage tank, and...

Embodiment 3

[0038] Such as figure 1 with figure 2 As shown, the construction technology for tunnel pavement seepage drainage device of the present invention comprises the following steps:

[0039] a chisel the drainage groove: clean the road area water, find the water seepage hole 16, use the cutting equipment to cut out two parallel slits until the slit is connected with the drainage ditch 12, and chisel the concrete in the slit to form the drainage groove 21;

[0040]b plugging the seepage hole: judge the water flow of the seepage hole 16, if the water flow of the seepage hole 16 is greater than the water flow of the drainage channel 2, then use double liquid grouting to consolidate the seepage hole 16; if the water flow of the seepage hole 16 is less than the water flow of the drainage channel 2 If the water flow rate is too high, durable resin polymerization waterproof material is used to consolidate the seepage hole 16;

[0041] c Install the drainage channel: buckle the U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com