Improved structure of water opening of diesel engine body

A diesel engine and water outlet technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of difficulty in improving diesel engine emission levels, increased after-sales failure rates of cylinder liners, and increased engine oil consumption, etc., to achieve a reduction in after-sales failure rates , The effect of reducing the deformation of the cylinder barrel and reducing the oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

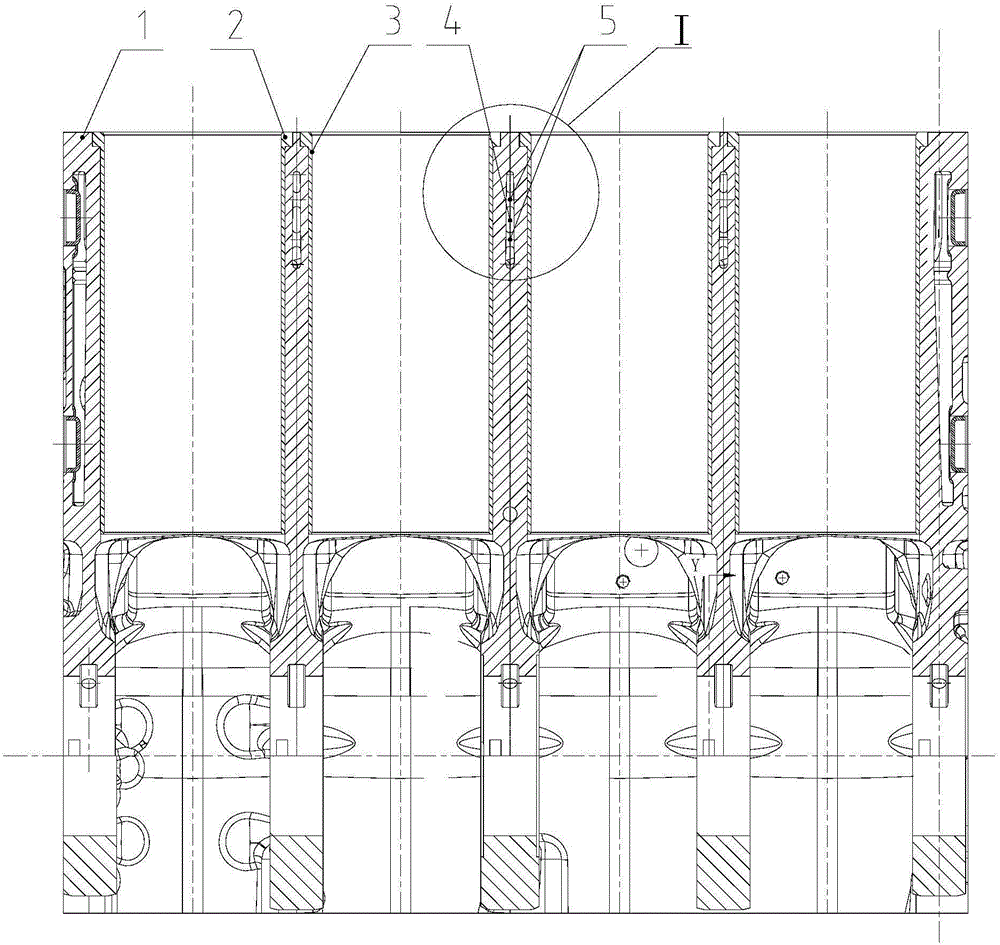

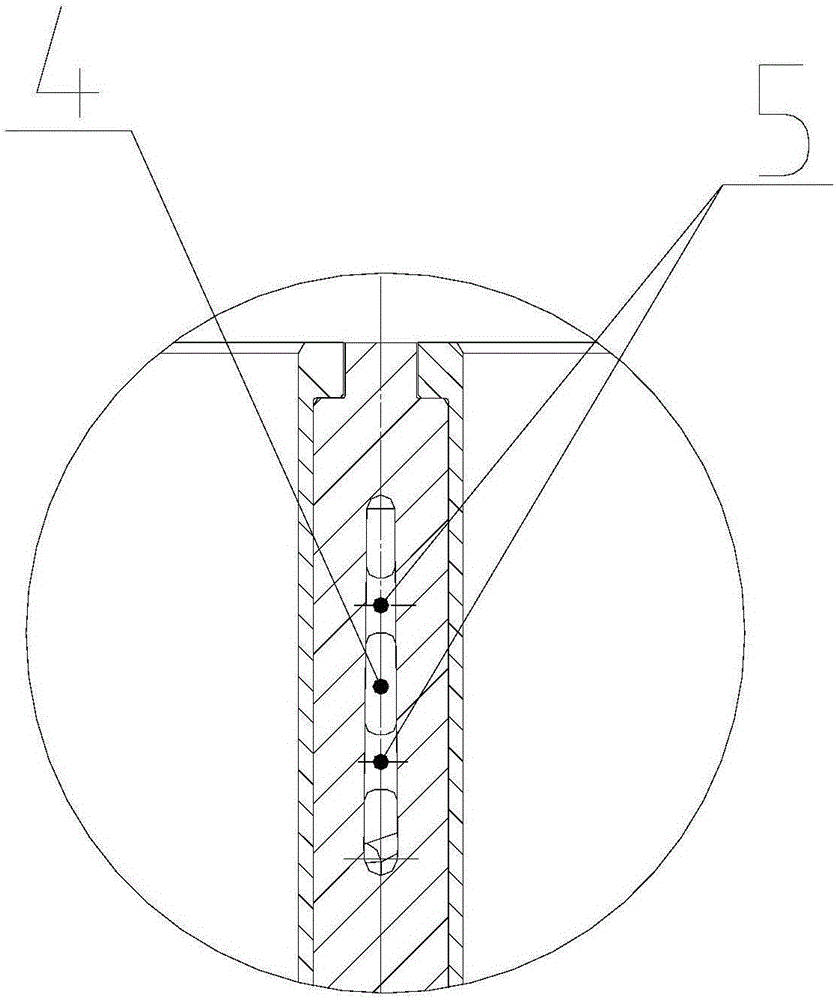

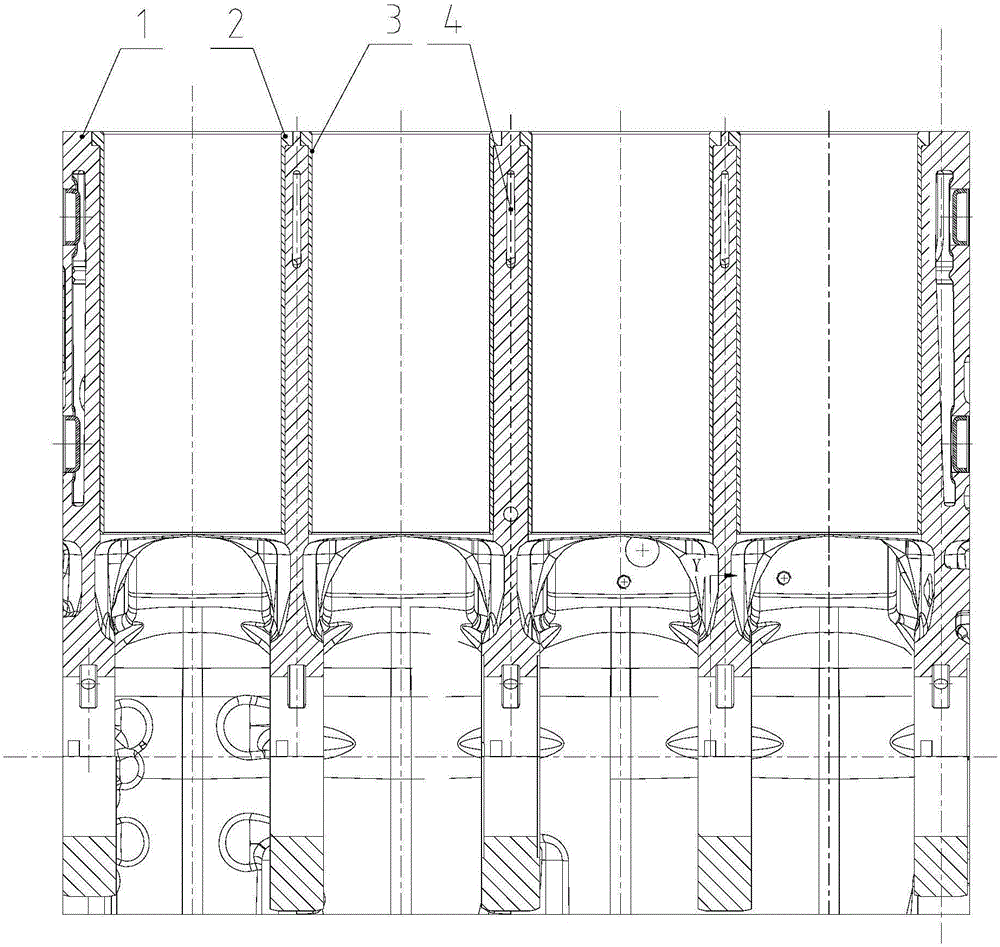

[0015] see figure 1 with figure 2 , an improved structure of the water inlet of a diesel engine body, including a cylinder block 1, several cylinder barrels 2 arranged on the cylinder block, adjacent cylinder barrels are separated by cylinder barrel walls 3, and the cylinder barrel walls are provided with A water hole 4 is arranged, and a supporting rib 5 is horizontally arranged in the water hole. There are 1 to 3 support ribs along the length direction of the water hole, preferably 2 in this embodiment. The support ribs are cast integrally with the cylinder wall.

[0016] In this way, under the condition that the cylinder center distance remains unchanged, the cylinder diameter can be appropriately increased; at the same time, the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com