Fully automatic multifunctional pumping machine

A pumping machine and multi-functional technology, which is applied in the direction of machines/engines, pumps, mechanical equipment, etc., can solve the problems of incapable of miniaturization, complex structure and principle, and shortened product life, so as to avoid unilateral eccentric force and reduce The weight of the whole machine and the effect of high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

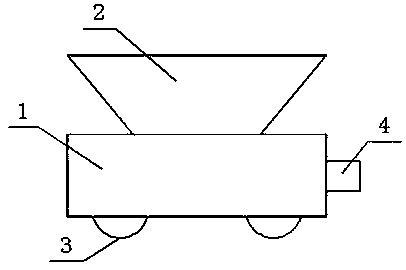

[0023] like figure 1 As shown, a fully automatic multi-functional pumping machine includes a pumping machine main body 1, a hopper 2 is arranged on the pumping machine main body 1, and a hopper corresponding to the above-mentioned hopper 2 is arranged inside the pumping machine main body 1 Pumping device, the lower part of the main body 1 of the pumping machine is provided with a running wheel 3, which is convenient for the transportation of the pumping machine.

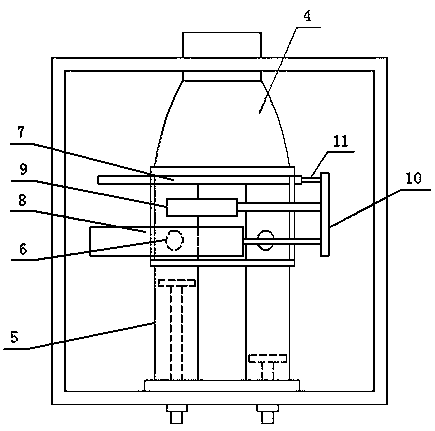

[0024] like figure 2 As shown, the pumping device is composed of two concrete delivery cylinders 5 arranged side by side and capable of continuous pumping and the pumping connector 4 provided at the end of the two concrete delivery cylinders 5. The concrete delivery cylinder in this embodiment 5 is two arranged side by side, of course, its number can also be greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com