A high-efficiency plate-type low-temperature radiator and its special components

A radiator and plate-type technology, which is applied in the field of high-efficiency plate-type low-temperature radiators and their special components, can solve the problems of inability to strengthen the heat transfer in the tube, low heat transfer of the radiator, and incompatibility of internal and external heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

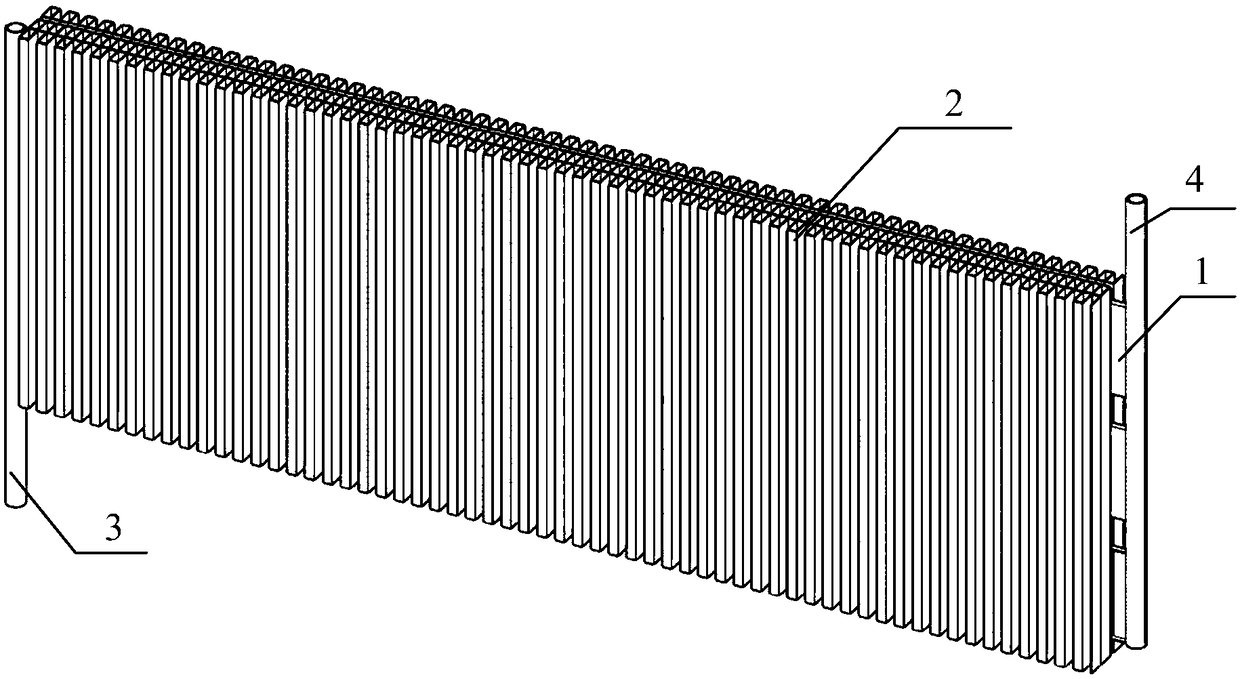

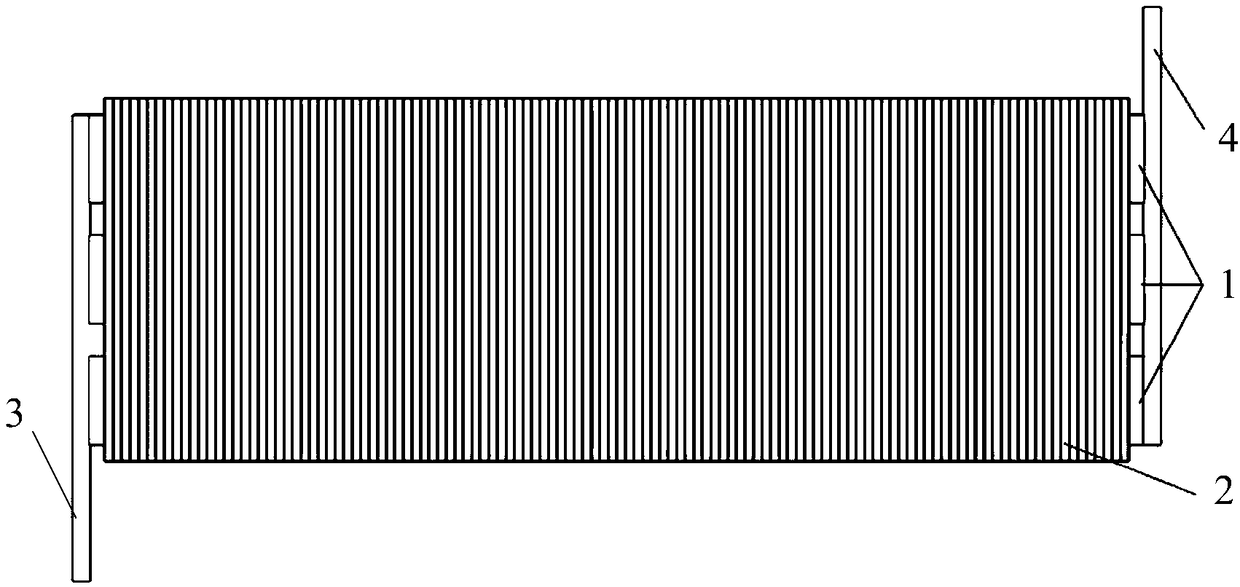

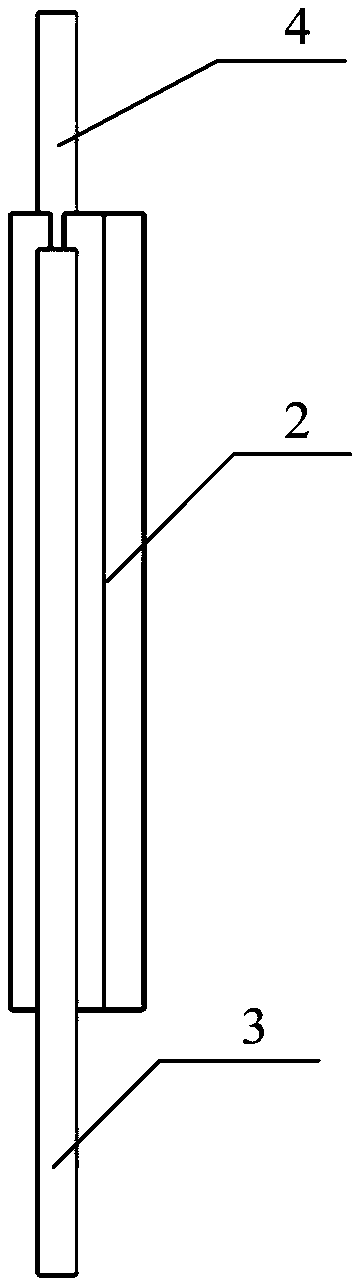

[0032] The present invention will be described below in conjunction with the accompanying drawings.

[0033] The invention relates to a high-efficiency plate-type low-temperature radiator, such as Figure 1a , Figure 1b , Figure 1c and Figure 1d The perspective view, front view, left side view and top view of a preferred structure, including the plate-shaped fine channel array enhanced heat exchange plate 1 and the heat exchange fins 2 combined with the plate-shaped fine channel array enhanced heat exchange plate 1, the plate Thin channel array enhanced heat exchange plate 1 is a plate-shaped structure with more than two thin channels arranged side by side to form a thin channel array formed by extruding metal materials. The equivalent diameter of the thin channel is 4mm-10mm. And the ratio of the long axis to the short axis of the thin channel is 0.5-2.0, preferably 0.8-1.2, and the plate-shaped thin channel array reinforced heat exchange plate 1 has holes respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com