Blade tip clearance real-time measurement system and method based on constant voltage alternating current discharge

A technology for real-time measurement of blade tip clearance, applied to measurement devices, electrical devices, electromagnetic means, etc., can solve the problems of friction between the blade tip and the inner wall of the casing, affecting the safety of the engine, and damage to parts, and achieves a novel measurement method. , Improve system stability and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

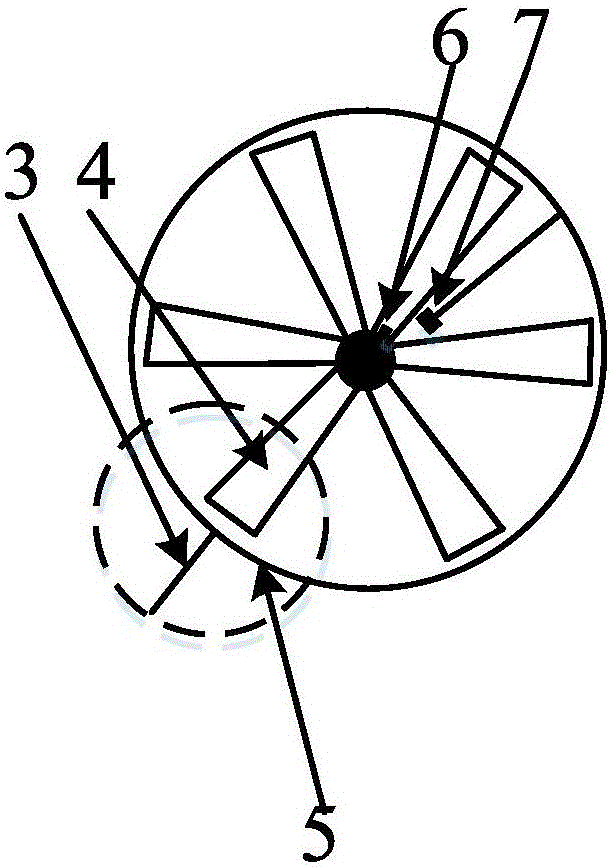

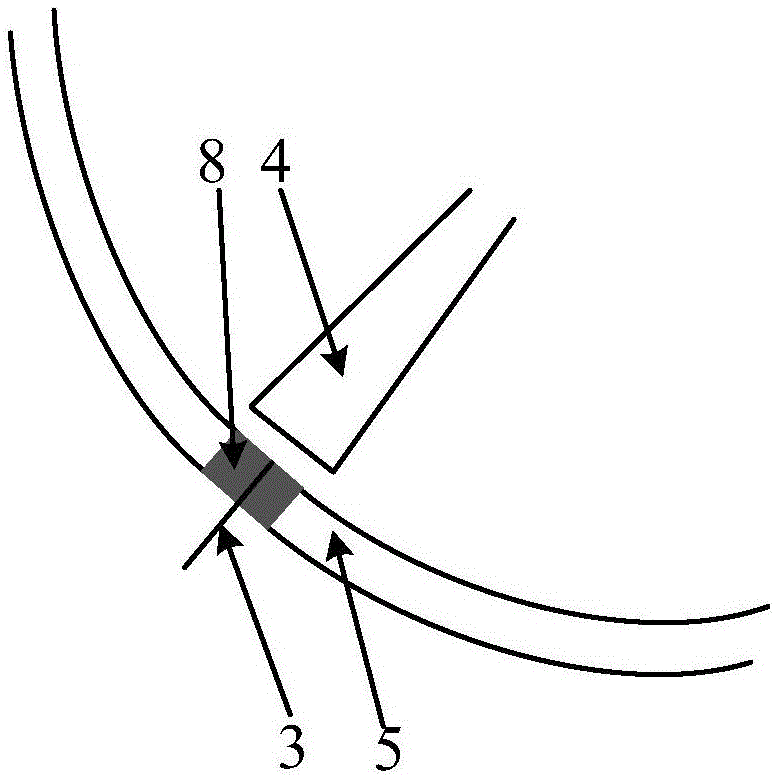

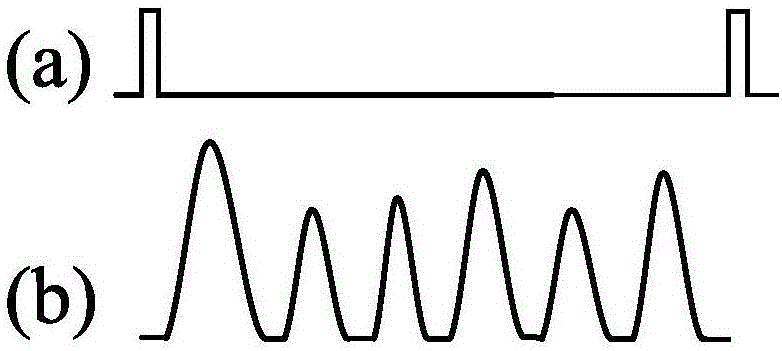

[0024] Such as Figure 4 As shown, the present invention provides a real-time measurement system for blade tip clearance based on constant-voltage AC discharge, including a high-frequency AC discharge voltage source 1, a negative feedback discharge coupling circuit module 2, a metal probe 3, a magnet 6, a Hall The sensor 7, the detection resistor 9, the voltage sensor 10, the analog-to-digital converter 11, the signal acquisition and conversion circuit 12 and the data processing module 13 will be introduced separately below.

[0025] A negative feedback discharge coupling circuit module 2 is connected in series between the high voltage end of the high frequency AC discharge voltage source 1 and the metal probe 3, and the cathode of the high frequency AC discharge voltage source 1 is connected to another negative feedback discharge coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com