Laser used vibration measurement device and its adjustment method

A technology for laser vibration measurement and equipment, which is applied to measurement devices, ultrasonic/sonic/infrasonic waves, instruments, etc., and can solve the problems of fixed working distance of vibration measurement equipment, increased manufacturing cost of vibration measurement instruments, and larger volume of vibration measurement instruments. , to achieve the effect of reducing the amount of manual operations, easy and convenient installation, reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

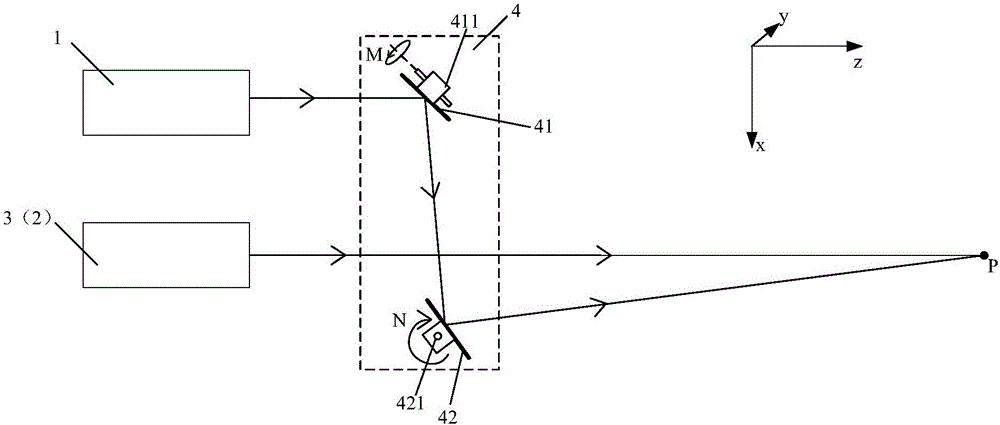

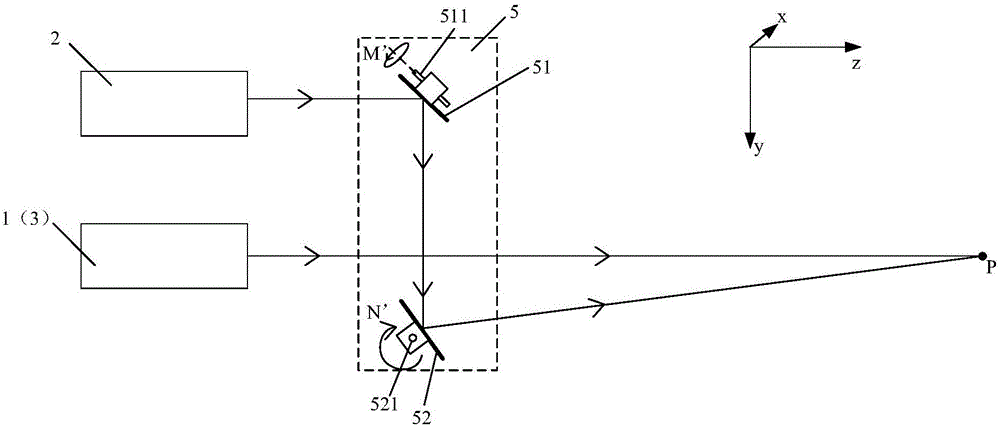

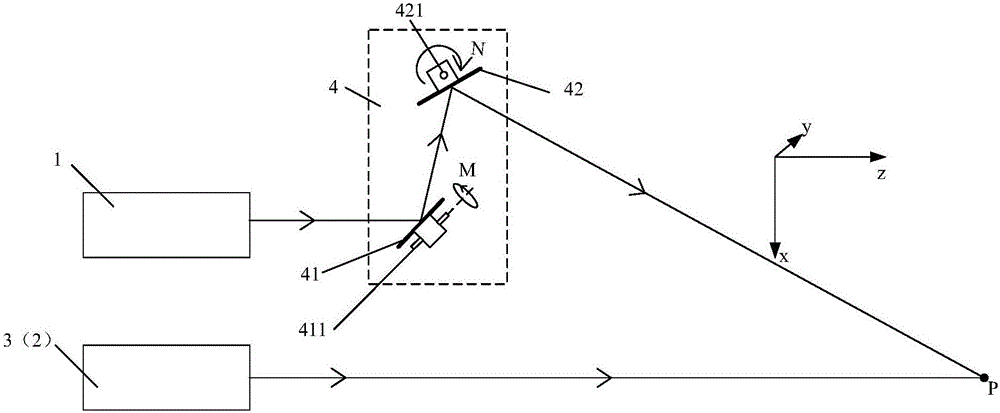

[0064] The description of this illustrative embodiment should be combined with the corresponding drawings, which should be taken as a part of the complete specification. In the drawings, the shape or thickness of the embodiments can be enlarged, and are marked for simplicity or convenience. Furthermore, the structural parts in the drawings will be described separately. It is worth noting that the elements that are not shown in the drawings or are not described by text are in the form known to those of ordinary skill in the art.

[0065] In the embodiments described below, the technical features in these embodiments will be described separately. These features may exist independently or in combination, and the present invention is not particularly limited to the preferred embodiments. The scope of the present invention is defined by the claims.

[0066] According to an embodiment of the present invention, a laser vibration measuring device is provided.

[0067] Such as figure 1 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com