Temperature measuring method and device, and product using the same

A temperature measuring device and temperature-sensitive technology, applied in the field of non-contact temperature measurement, can solve the problems of difficult measurement, large error, slowness, etc., and achieve the effect of simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

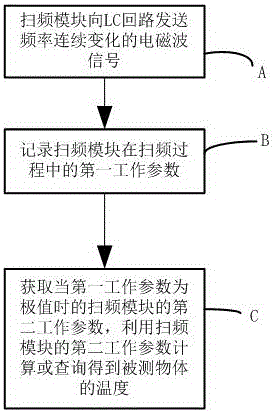

[0041] This embodiment discloses a temperature measurement method, which uses the resonance principle and the combination of the magnetic permeability and temperature change characteristics of the temperature-sensitive magnet to realize non-contact temperature measurement.

[0042] Specifically, an LC loop is provided, and the LC loop includes an inductor and a capacitor connected to the inductor. The iron core of the inductor is a temperature-sensitive magnetic core, and the temperature-sensitive magnetic core is in contact with the measured object to sense the temperature of the measured object (of course In practical application, it is not necessarily necessary for the temperature-sensitive magnetic core to be in contact with the measured object to sense the temperature of the measured object. The technical means of sensing the temperature of the measured object are all within the protection scope of the present invention). In practical applications, the temperature of the ...

Embodiment 2

[0053] This embodiment is an optimization to embodiment 1, see figure 2 ,Specifically:

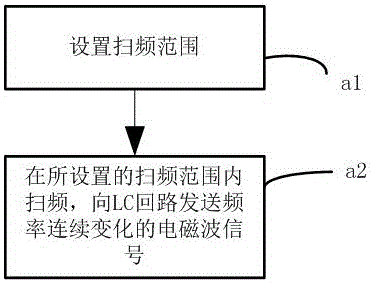

[0054] a1. Set the frequency sweep range.

[0055] a2. Sweep within the set frequency sweep range, and send an electromagnetic wave signal of equal amplitude with continuously changing frequency to the LC loop.

[0056] In this embodiment, according to the characteristics of the LC circuit and the possible temperature range of the object, the frequency sweep range can be reasonably set in priority, and the frequency sweep work can be continuously carried out within this range, which can improve the efficiency and efficiency of detecting the resonance of the LC circuit. accuracy.

Embodiment 3

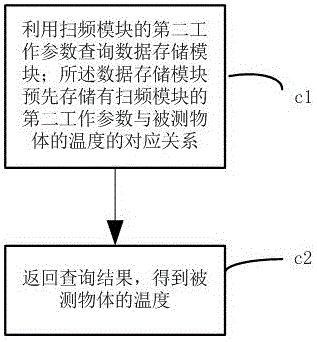

[0058] This embodiment is basically the same as Embodiment 1, the difference is that this embodiment proposes a method of querying the temperature of the object to be measured by using the obtained second working parameter of the frequency sweep module, such as image 3 As shown, in step C, the following steps are included:

[0059] c1. Utilize the second working parameter of the frequency sweep module to query the data storage module; the data storage module pre-stores the correspondence between the second working parameter of the frequency sweep module and the temperature of the measured object; in practical applications, the second working parameter includes The output frequency of the frequency sweep module or electrical parameters that can be accurately derived to obtain the output frequency of the frequency sweep module. From the analysis of the above-mentioned embodiment 1, it can be known that when the LC circuit resonates, the output frequency of the frequency sweep m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com