Test device for splitting tensile fracture under impact-static-hydraulic coupling effect of rock and test method

A hydraulic coupling and static technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Simple, good experimental effect, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

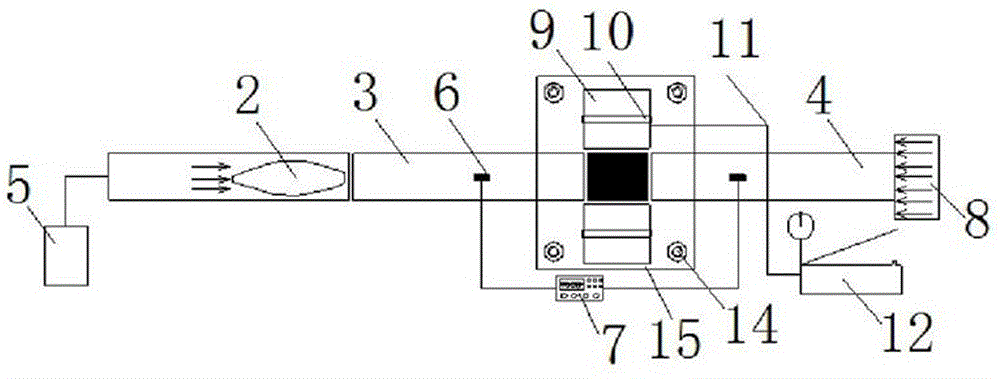

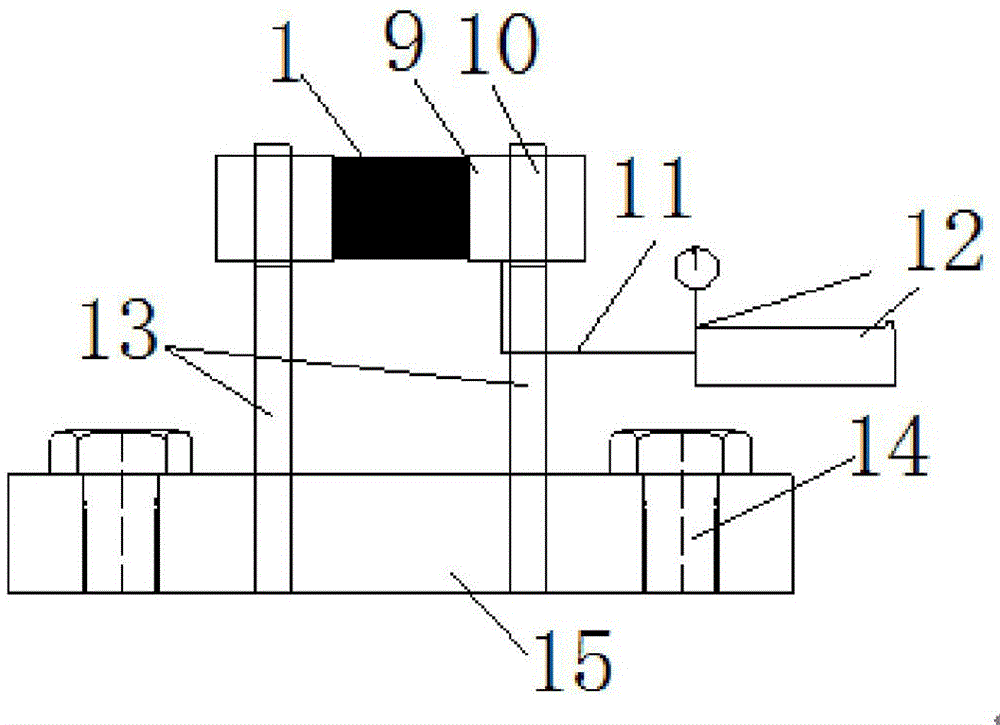

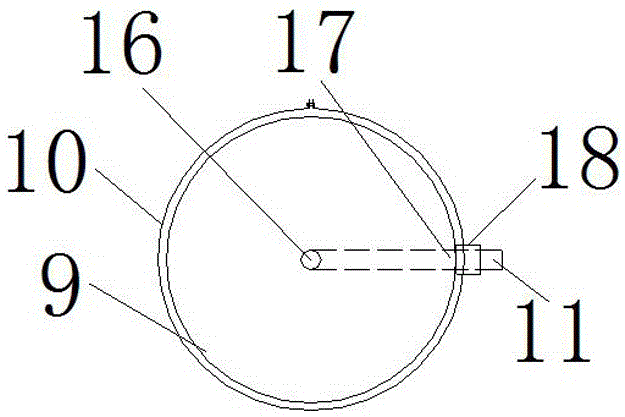

[0015] like figure 1 , 2 , shown in 3, a kind of experimental device for rock impact-static force-hydraulic coupling splitting tensile failure mechanics comprises: base 15, Hopkinson compression bar device and hydraulic pressure loading device, described Hopkinson compression bar device It consists of a high-pressure tank 5, a bullet 2, an incident rod 3, a strain gauge 6, a data acquisition instrument 7, a transmission rod 4 and an axial static pressure loading device 8. In this embodiment, the test piece 1 is clamped radially Between the incident rod 3 and the transmission rod 4, the incident rod 3 and the transmission rod 4 are tightened to clamp the specimen 1, the base 15 is fixed on the Hopkinson pressure bar device through four bolts 14, and the hydraulic loading device passes through the pillar 13 Fixed on the base 15, the pillar 13 is welded on the base 15, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com