Pear surface defect detection method based on machine vision

A machine vision, defect detection technology, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve the problems of lax grading, rough packaging, reduced value and competitiveness, and achieve the effect of simple and easy-to-implement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The collected images must firstly undergo certain preprocessing operations, including image conversion and image enhancement.

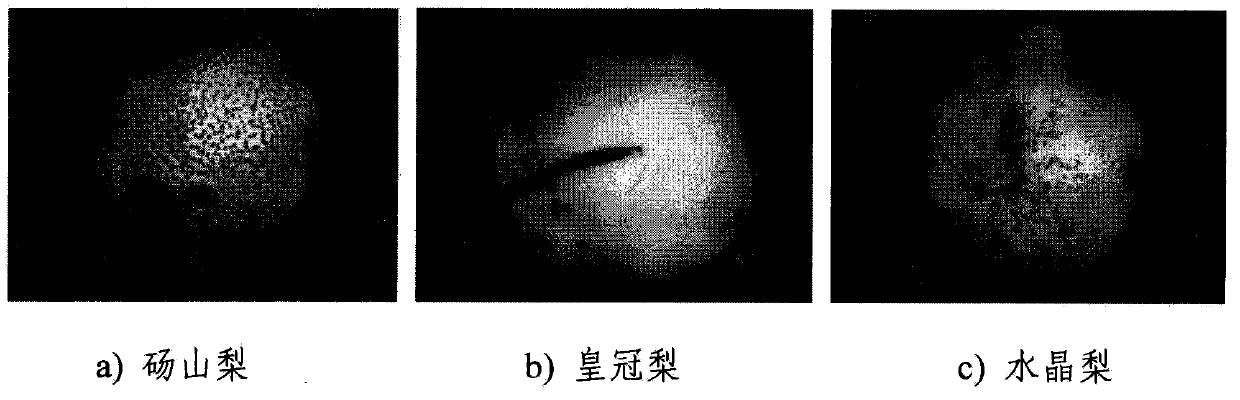

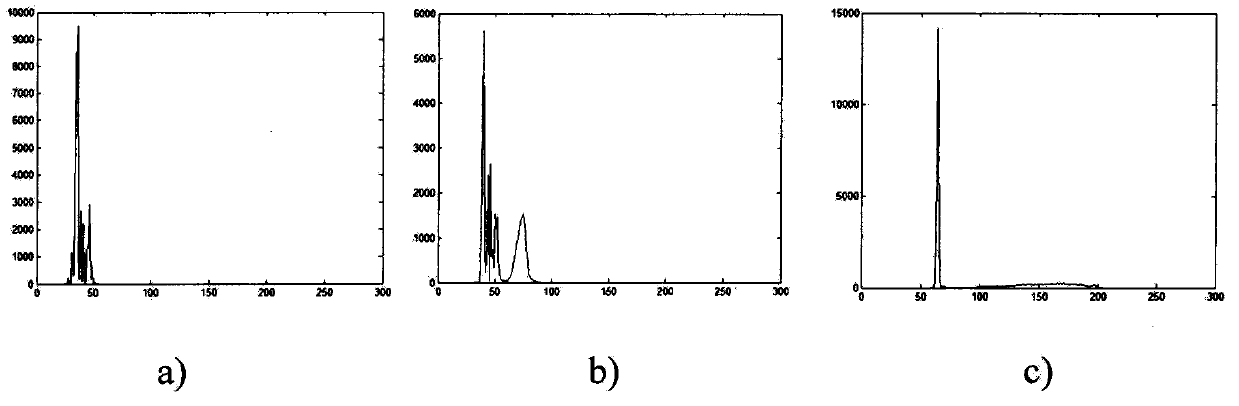

[0035] The image conversion of the collected color pear image includes: gray scale and RGB-HSI color space conversion. Color image, which contains a large amount of information, can extract a large amount of image information required by this topic, so as to achieve the purpose of defect identification. The grayscale image contains less information and cannot truly reflect and describe the objective reality, but it is precisely because of this feature that the grayscale image occupies less storage space and the amount of calculation for digital processing is small. Therefore, in image processing In the process, it is necessary to convert the color image into a grayscale image to facilitate processing and improve detection efficiency, such as figure 1 As shown in , it is the effect diagram after graying the three kinds of pears respectively.

...

Embodiment 2

[0041] The present invention adopts the segmentation method based on the template method when performing the background removal operation on the obtained pear image, and the flow chart is as follows Image 6 shown. The method is described as follows:

[0042] 1) Use the hardware equipment selected by design to shoot pears to obtain pear images with various defects;

[0043] 2) the pear image that is obtained is carried out preprocessing, has carried out analysis explanation in embodiment 1, has carried out gray scale and linear transformation;

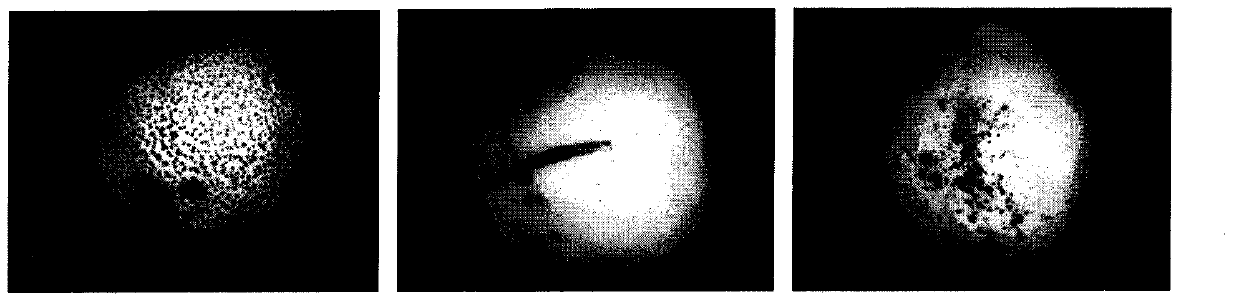

[0044] 3) Perform binarization and denoising on the preprocessed image. The binarization and denoising processing here is to obtain a binary image with a black background and a white pear, so the morphological denoising used here The filter window can be made larger;

[0045] 4) Generate a background template and invert the logic of the binary image to obtain the template image. The template image is a binary image of the same size as...

Embodiment 3

[0051] After the background removal operation is performed, the defect is extracted on its I component, and the flow chart is as follows Figure 8 shown. The method is described as follows:

[0052] 1) extract the I component map from the pear image after removing the background, and carry out post-processing on it;

[0053] 2) Binarize the I component map. Here, the Otsu segmentation threshold method is used. The Otsu method chooses to maximize the variance between classes The threshold k of , the between-class variance is defined as

[0054] σ B 2 = w 0 ( u 0 + u T ) 2 + w 1 ( u 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com