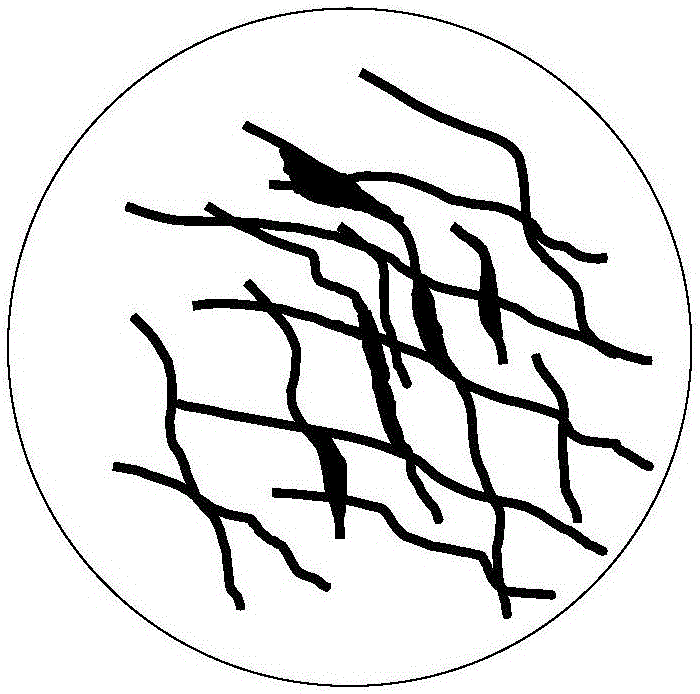

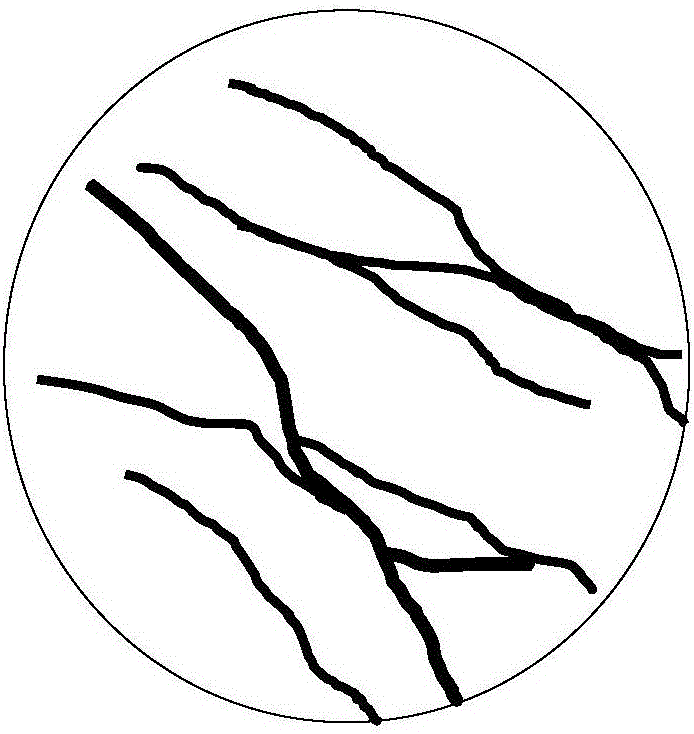

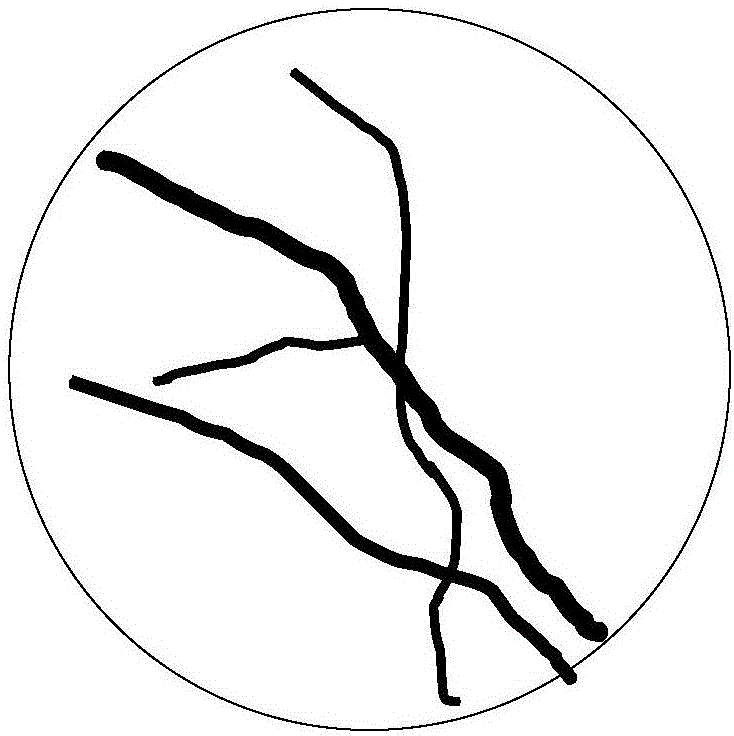

Construction method for micro fracture-pore structure classification plate of granite reservoir

A technology of pore structure and micro-fractures, applied in suspension and porous material analysis, material analysis, permeability/surface area analysis, etc., can solve problems such as classification basis, complex carbonate storage space types, and inaction of fracture parameters. , to achieve the effect of strong operability, great applicability and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] A method for constructing a microscopic fracture-pore structure classification map of a granite reservoir of the present invention comprises the following steps:

[0037] 1) Select the core section of the target reservoir. In order to truly reflect the development characteristics of fractures as much as possible, the core section that has not suffered artificial damage should be selected.

[0038] 2) Measure the porosity and permeability of the small column sample in the core section, and conduct CT scanning and mercury injection displacement experiments on the small column sample in the core section. Specifically include the following steps:

[0039] ①Measure the porosity and permeability of the small column sample in the core section, and obtain the basic porosity and permeability parameters of the small column sample in the core section.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com