Remote sensing data quality inspection subsystem

A technology for remote sensing data and subsystems, applied in the field of quality inspection, can solve the problems of inconvenient use, inaccurate flaw detection, danger of X-ray flaw detection instruments, etc., and achieve the effect of clear working principle and reasonable module structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

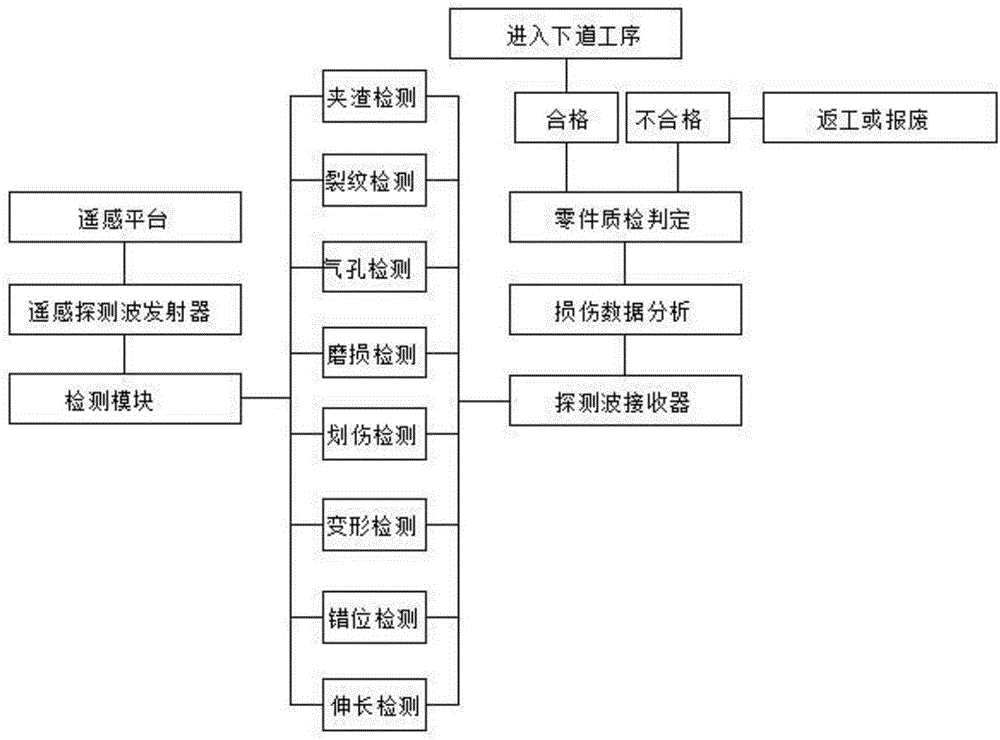

[0015] Such as figure 1 As shown, the remote sensing data quality inspection subsystem includes a remote sensing platform, a remote sensing detection wave transmitter and a detection wave receiver; it is characterized in that: the remote sensing wave transmitter is connected to a detection module, and the detection module includes slag inclusion detection, crack detection Detection, porosity detection, wear detection, scratch detection, deformation detection, dislocation detection and elongation detection, the detection module is connected to the detection wave receiver, and the detection wave receiver is connected to the damage data analysis module, through the damage data After analysis, the analysis module transmits the damage data to the part quality inspection and judgment, and if it is judged qualified, it will enter the next process, and if it is judged unqualified, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com