System and method for testing secondary circuit on site in intelligent substation

A smart substation and secondary circuit technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of long distance between equipment at the interval layer and equipment at the process layer, unfavorable secondary circuit testing, etc., to improve test efficiency, The effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical effects of the present invention will be described in further detail below in conjunction with the accompanying drawings.

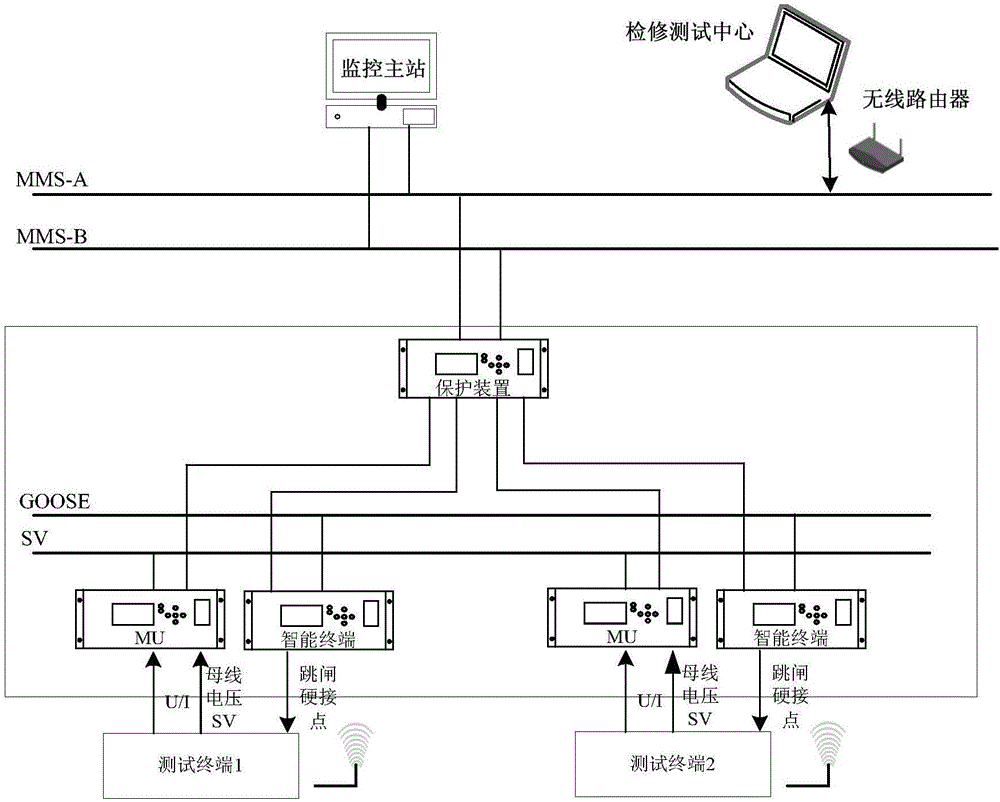

[0023] Embodiment of Field Test System for Secondary Circuit in Intelligent Substation of the Present Invention

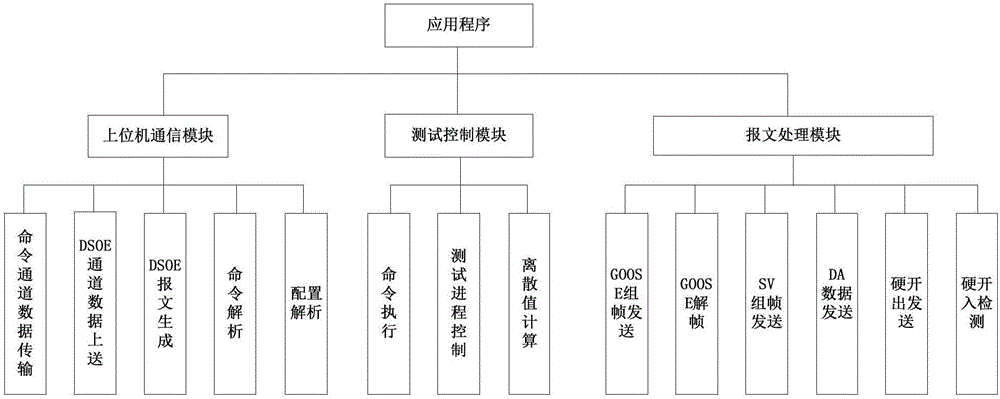

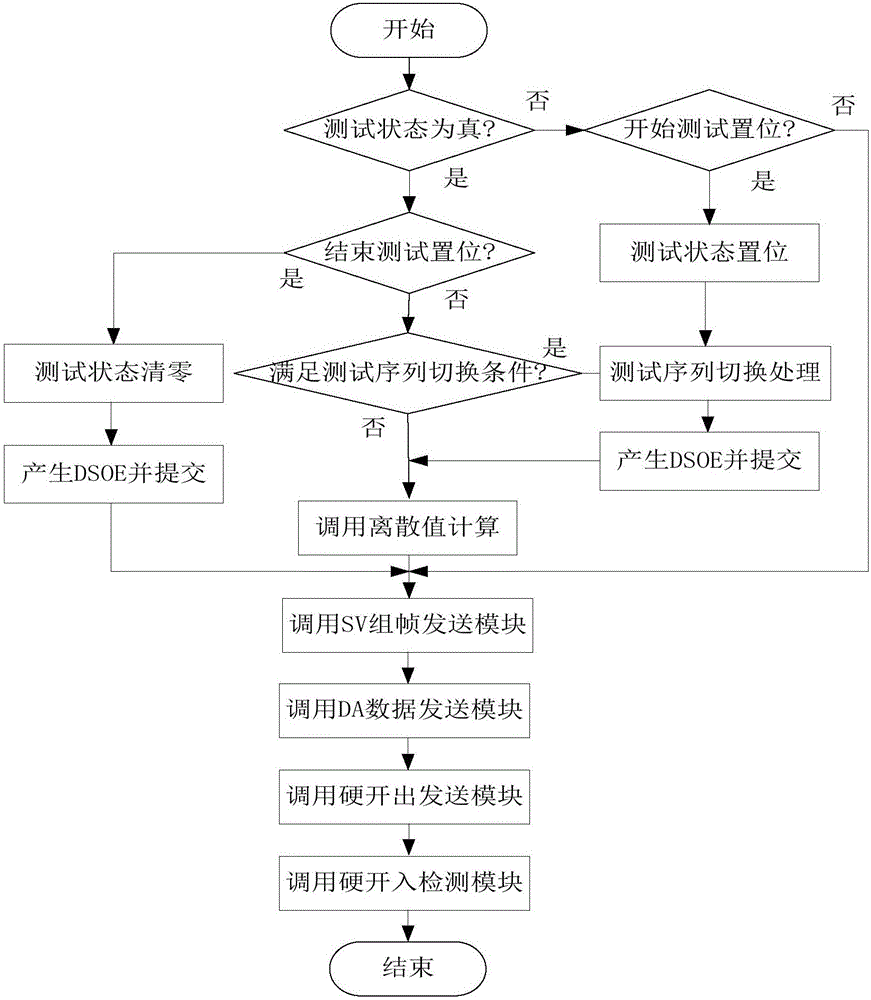

[0024] The on-site test system for the secondary circuit in the smart substation of this embodiment includes a maintenance test center and at least one test terminal connected to the maintenance test center; The test equipment sends analog or digital signals, and collects the exit node information of the secondary circuit to be tested; the maintenance test center is used to set the test data of each test terminal, and sends it to each test terminal, and receives the secondary circuit to be tested. The test feedback data of the equipment and the MMS information of the protection device are used to judge the correctness of the equipment under test of the secondary circuit according to the test feedback data and MMS informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com