Dieless hydraulic quasi-static thin-plate bulging deformation limit strain and load graphic calculation method

A limit strain, quasi-static technology, applied in the direction of calculation, computer-aided design, special data processing application, etc., to achieve the effect of simple and clear calculation process, simple method and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

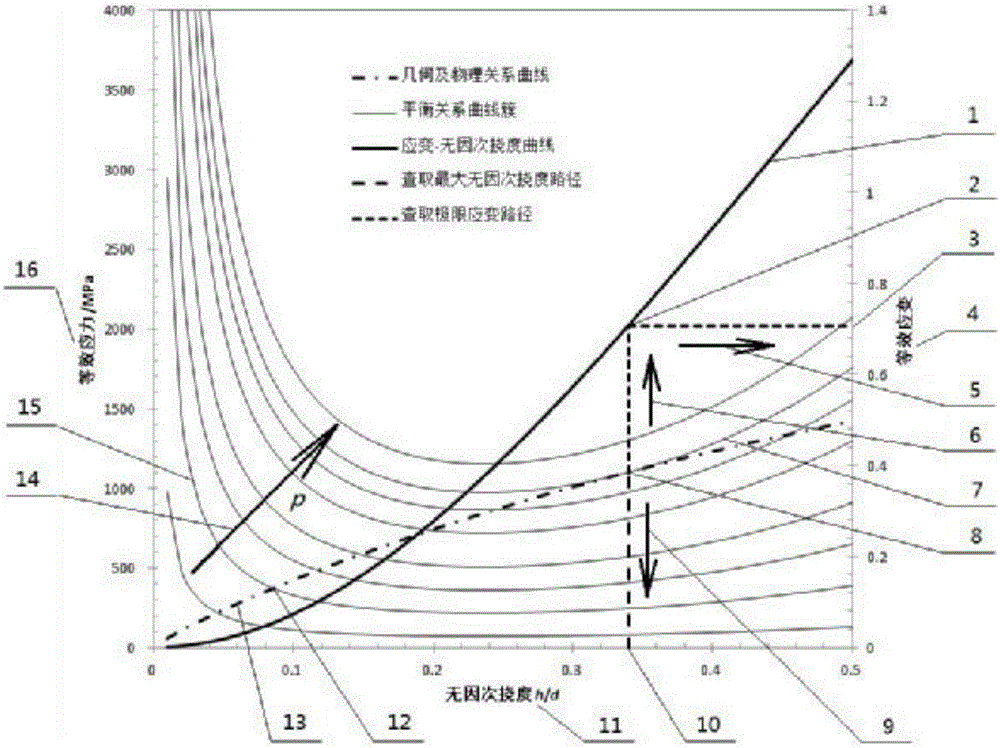

[0050] refer to figure 1 , the graphic calculation method of the moldless hydraulic quasi-static thin plate bulging deformation limit strain and load of the present embodiment includes the following steps:

[0051] S1: Take the dimensionless deflection as the abscissa 11, take the von Mises equivalent stress as the left ordinate 16, and get the von Mises equivalent as the right ordinate 4; the dimensionless deflection is the extreme top central deflection h and bearing pressure The ratio h / d of the zone diameter d ranges from greater than 0 to less than or equal to 0.5.

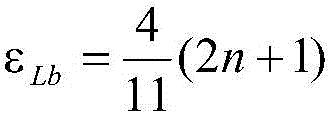

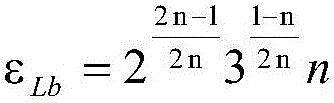

[0052] S2: Simultaneous formula (1) and formula (3),

[0053] ε e =αln[1+4(h / d) 2 ] (1)

[0054]

[0055] σ e =f(ε e ) (3)

[0056] In the formula, σ e , ε e and h are the von Mises equivalent stress, equivalent strain and deflection at the center of the pole top respectively, α and β are two key control parameters, f(ε e ) represents the functional relationship between the equivalent stress and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com