Soft copper conductor for connecting electrical components

A technology of electrical components and conductors, applied in the field of soft copper conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

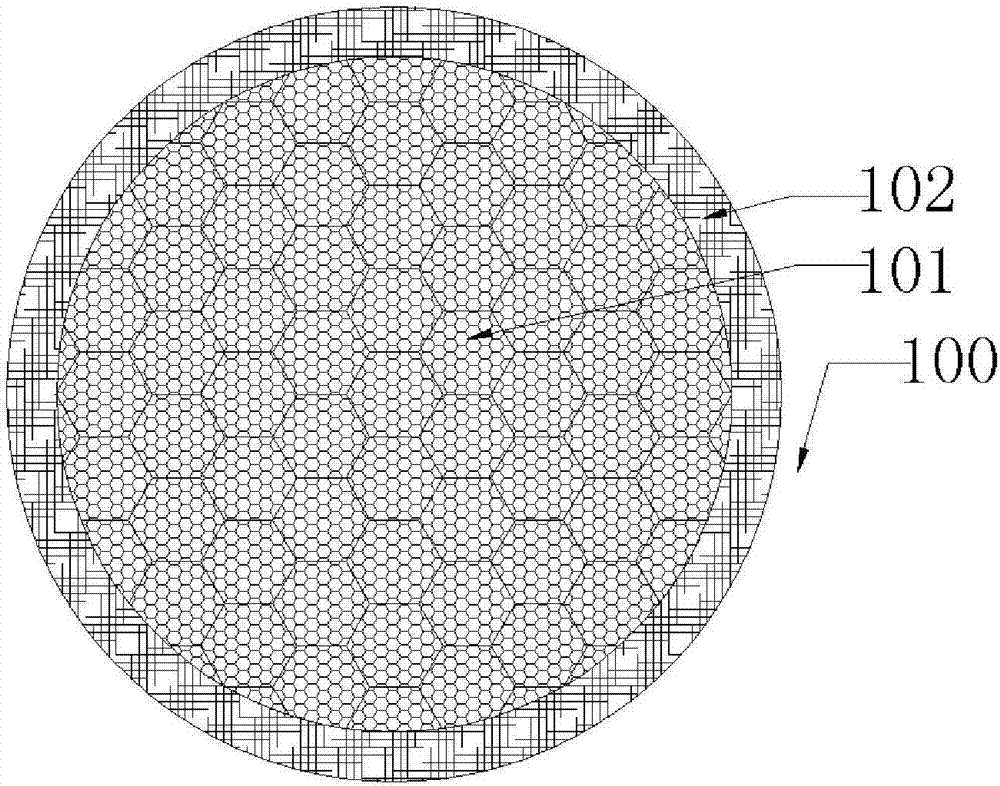

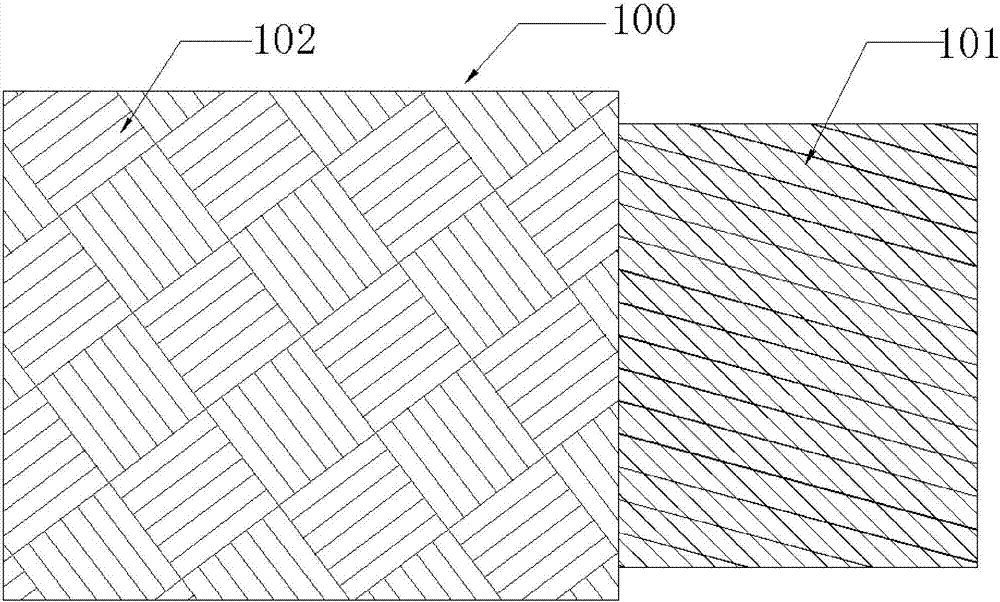

[0018] see figure 1 and figure 2 , the annealed copper conductor 100 (hereinafter referred to as annealed copper conductor) that provides in this example for connecting electrical components is mainly to divide an annealed round copper wire of an annealed copper conductor into two parts, and a part of annealed round copper wire is used to form an annealed copper brush wire The structure is the conductor body 101 of an annealed copper conductor, and another part of annealed round copper wire is braided on the outer surface of an annealed copper brush wire (i.e., the conductor body 101) to form an annealed copper conductor conductor weaving layer 102. The copper brush wires are bundled together.

[0019] The annealed copper conductor 100 of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com