Battery module and electric vehicle

A technology of battery components and cells, applied in battery pack components, electrical components, secondary batteries, etc., to achieve good cooling effect, good performance, and save overall space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

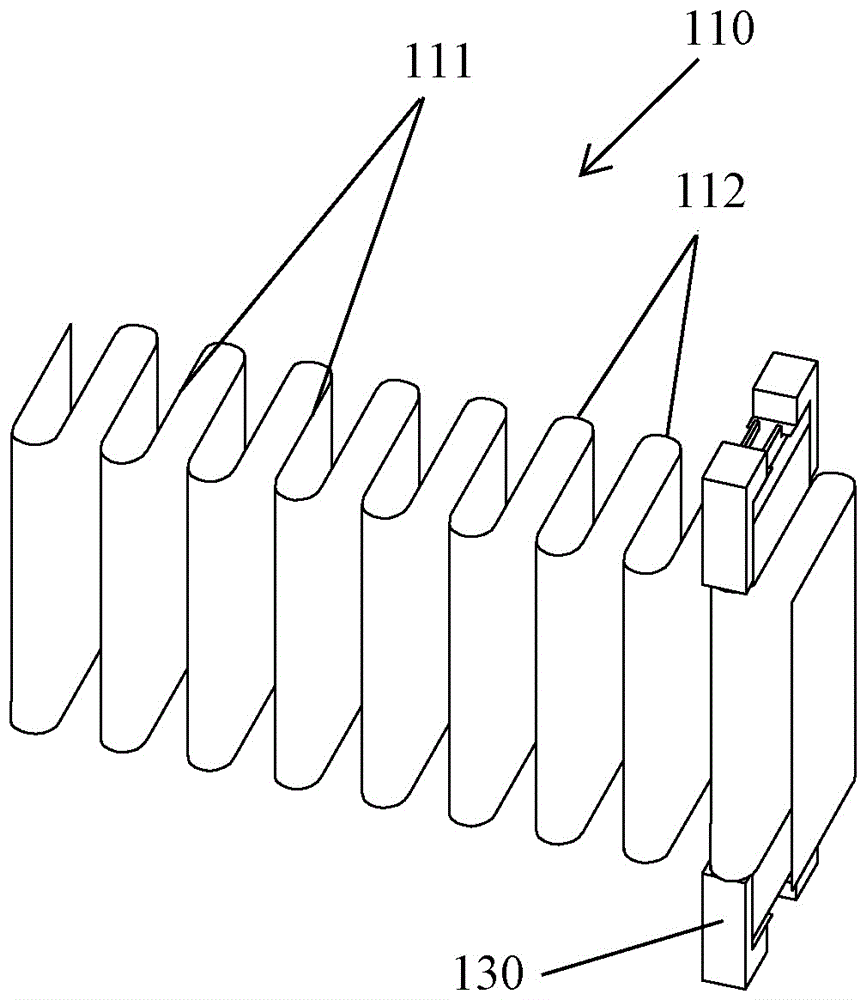

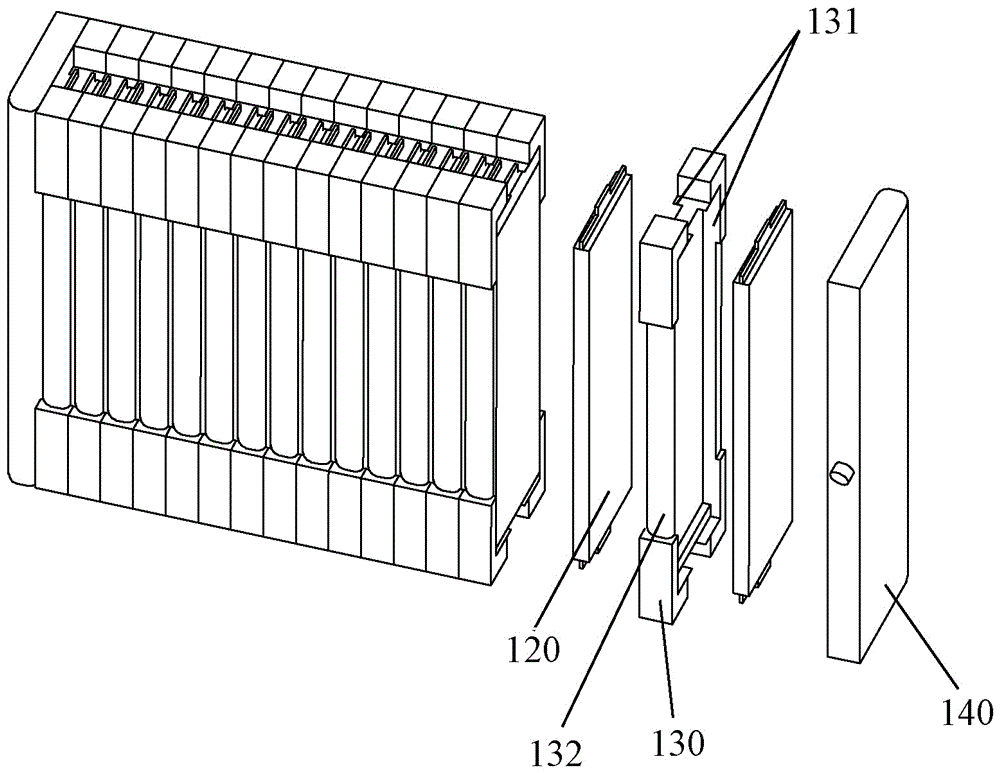

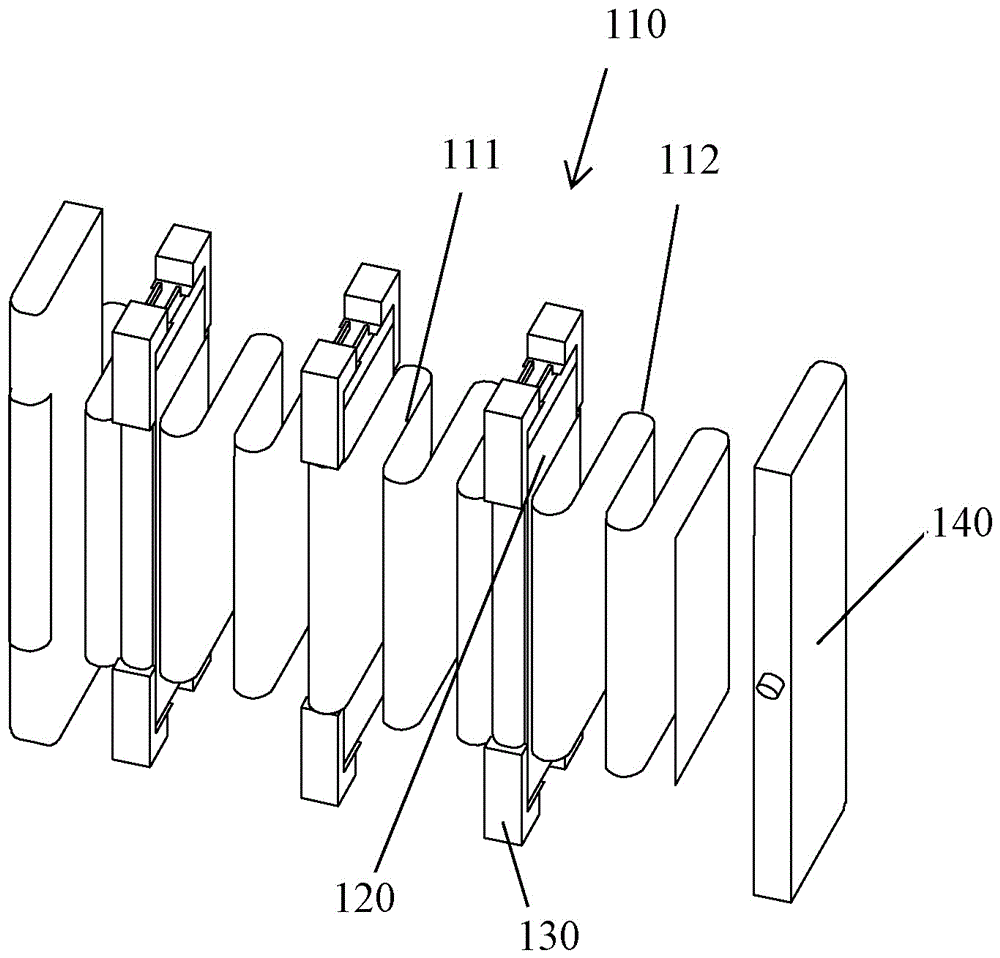

[0020] figure 1 An embodiment of an assembled battery assembly 100 is shown, which includes a plurality of cells 120 , a plurality of cell positioning components 130 , a cooling plate component 140 and a heat conducting film 110 . Wherein, the heat conduction film 110 is shuttled and arranged between the electric core 120 and the electric core positioning part 130 in the form of reciprocating folding, and finally connected to the cooling plate part 140 . During the working process, the heat absorbed from the battery cell 120 passes through the entire heat conduction film 110 or a partial section of the heat conduction film 110 and is conducted to the cooling plate member 140 to dissipate heat, thereby cooling the battery cell 120 . The battery assembly 100 of this embodiment only uses the heat conduction film 110 to complete the entire heat dissipation process. While achieving a good cooling effect on the battery cells, it does not need to occupy too much space for the heat di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com