A vibration motor grounding structure and automobile

A vibration motor and grounding structure technology, applied in the direction of connection with grounding devices, can solve problems such as poor contact, difficult assembly, and high assembly accuracy requirements, and achieve the effects of stable grounding effect, simple structure and reliable contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

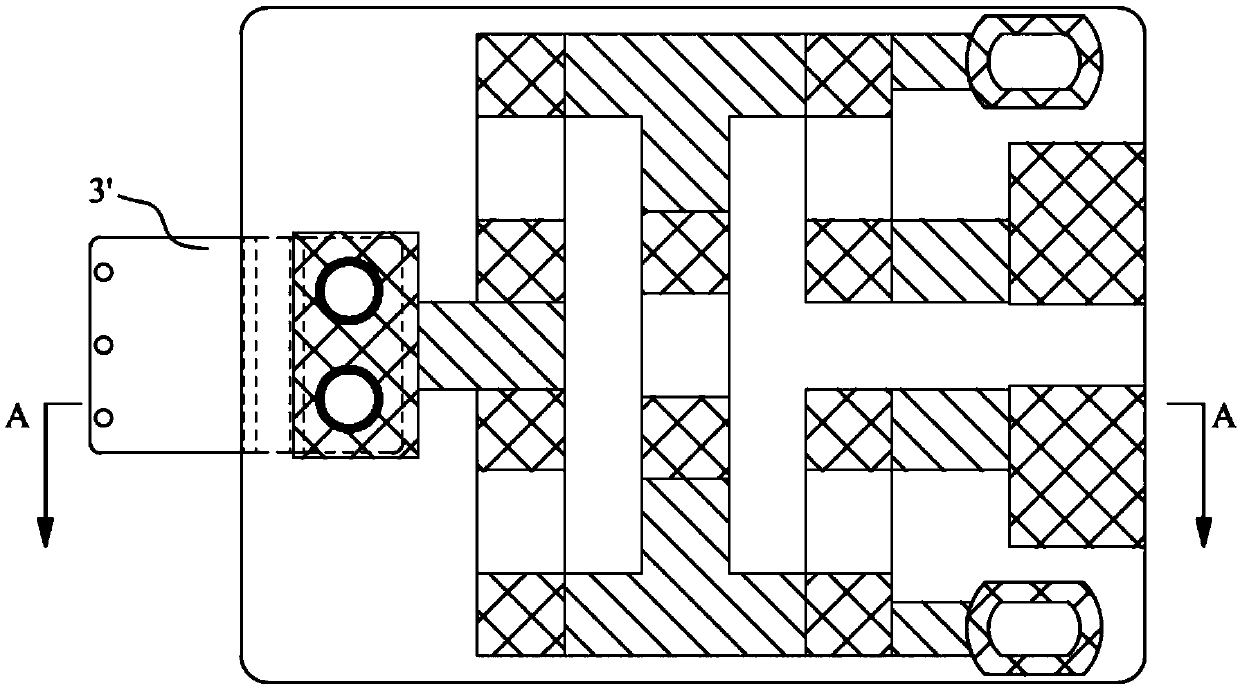

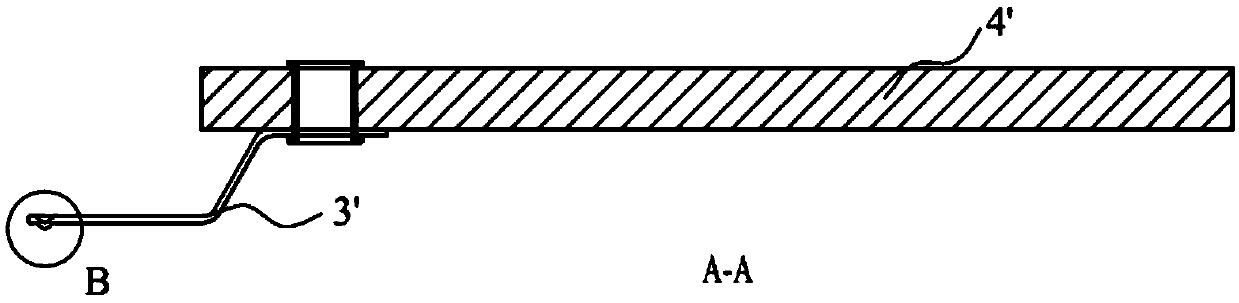

[0040] Such as Figure 7-17 As shown, this embodiment provides a grounding structure for a vibration motor, including a metal bracket 2, a vibration motor, and a metal connector 3. The vibration motor includes a motor body 1 and a PCB board 4 electrically connected to the terminals of the motor body 1. 1 is fixed to the metal bracket 2, the PCB board 4 is used to control the vibration of the vibration motor body 1; the metal bracket 2 is provided with a connection hole; one end of the PCB board 4 is the connection end, the metal connection piece 3 is fixed to the connection end, the metal connection piece 3 A resilient piece 31 protruding outward is provided, and the connecting end and the metal connector 3 extend into the connecting hole, and the resilient piece 31 and the connecting end respectively abut the inner wall of the connecting hole to realize the design of the vibration motor grounding.

[0041] Compared with the prior art, the metal bracket 2 in this embodiment is pro...

Embodiment 2

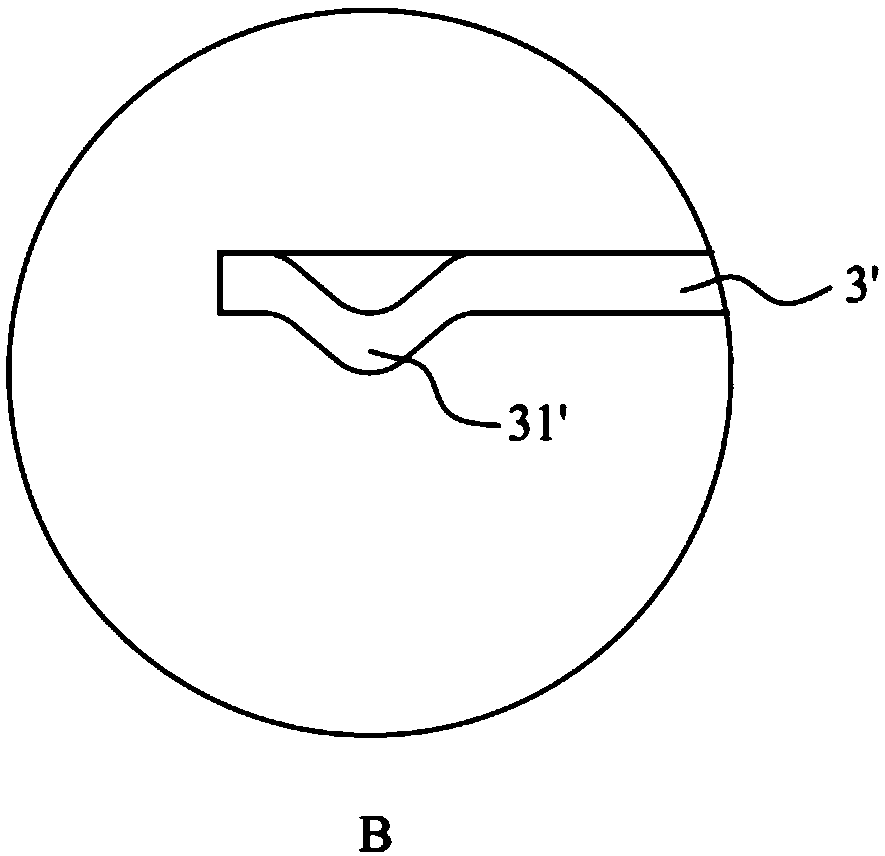

[0046] This embodiment provides an automobile, including a steering wheel, and the grounding structure of the vibration motor provided in Embodiment 1 is provided in the steering wheel. Compared with the prior art contacting the shell of the vibration motor through the bump 31' on the metal connector 3', the metal connector 3 in the grounding structure of the vibration motor has a reliable contact with the metal bracket 2, and the motor is grounded. The effect is stable, and the structure of the metal connector 3 is simple and easy to assemble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com