Conductive earthing member, cable component and production method thereof

A technology of cable assembly and manufacturing method, which is applied in the field of conductive grounding parts, can solve the problems of not being suitable for connecting multiple cables, the grounding wire 31 is fragile, and affects the grounding effect, and achieves the effects of easy application, simple manufacture, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

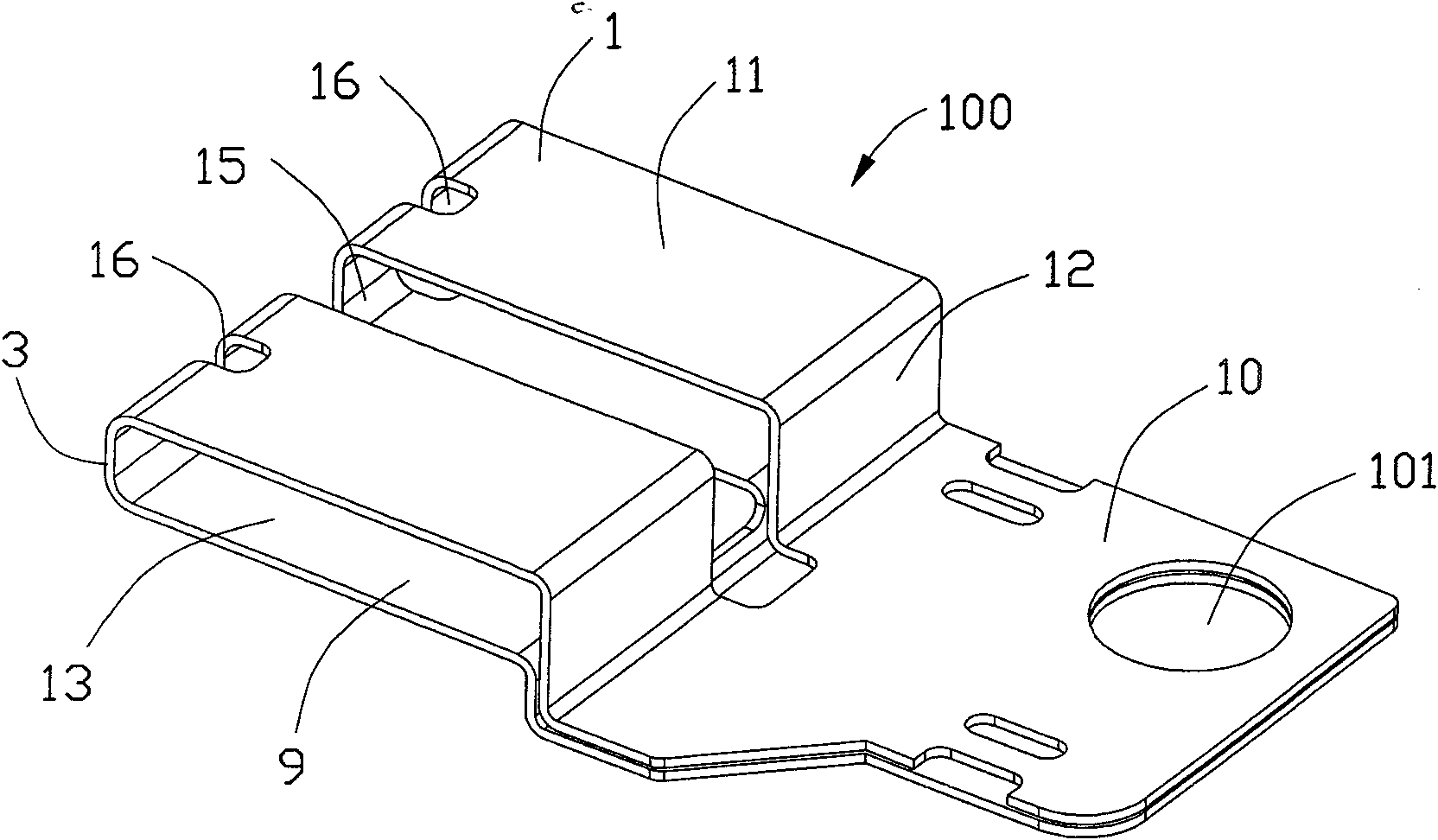

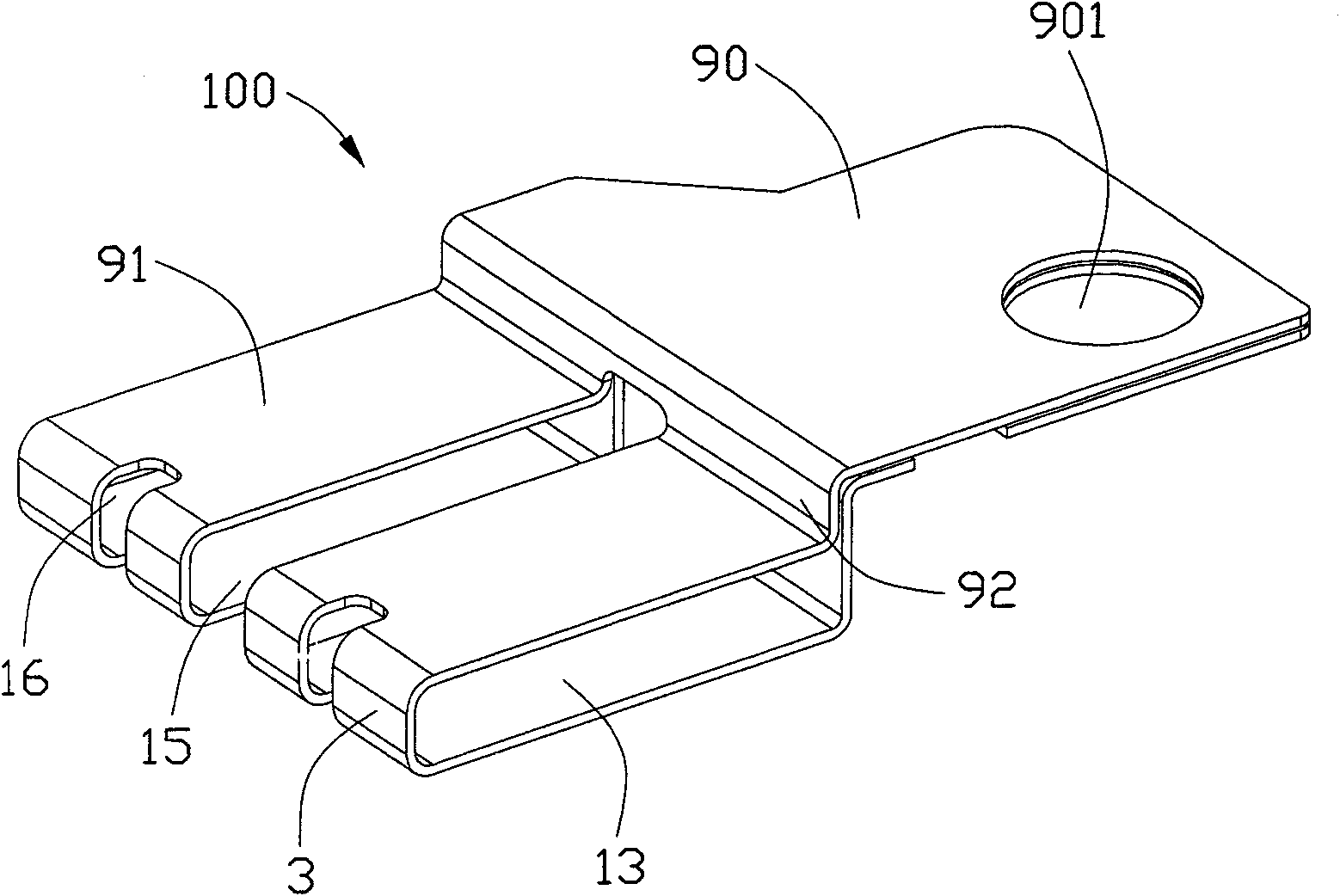

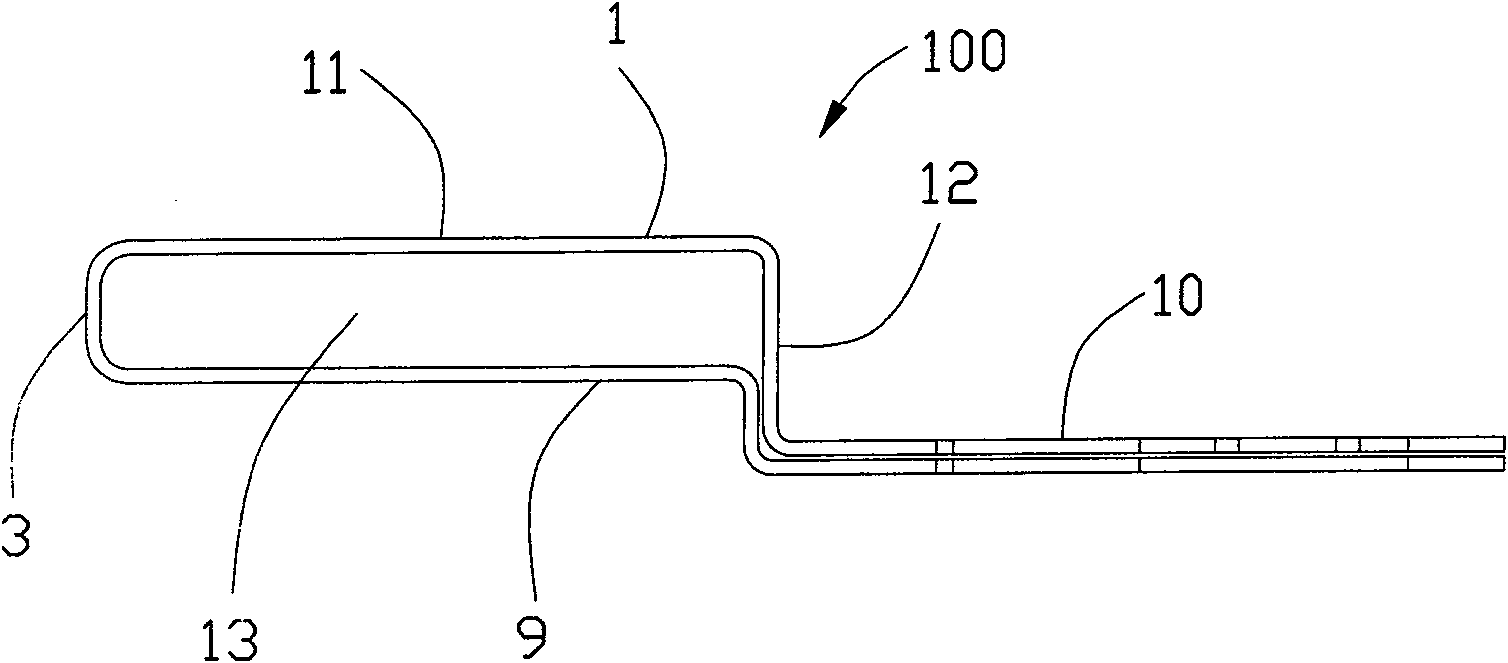

[0031] In the first and second embodiments, the cable assembly is applied to a notebook computer, which includes conductive grounding elements 100, 100' and several wires (not shown). The wires include several power lines and several signal lines. Each power cord includes a core wire and an insulating layer covering the core wire. Each signal wire includes a core wire, an inner insulating layer covering the core wire, a conductive shielding layer covering the inner insulating layer, and an outer insulating layer covering the conductive shielding layer. , 100' electrical connection. Similar to the prior art disclosed in Chinese Invention Patent Publication No. CN 1503411A, one end of the power line and the signal line are electrically connected to the first connector (not shown), and the other end of the power line is electrically connected to the second connector (not shown) to transmit power between the first and second connectors, and the other end of the signal line is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com