Omnidirectional tracking photovoltaic power generation equipment

A photovoltaic power generation equipment and all-round technology, applied in photovoltaic power generation, photovoltaic modules, solar thermal power generation, etc., can solve the problems of photovoltaic power generation equipment being difficult to popularize, and the angle change range is large, so as to achieve good overall structure rigidity, stable and reliable support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

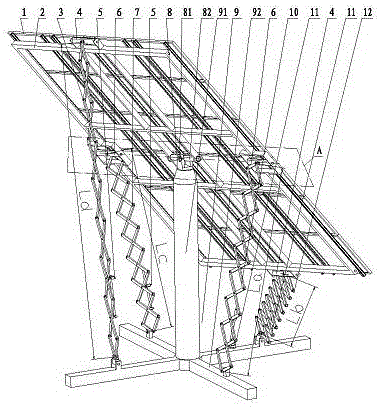

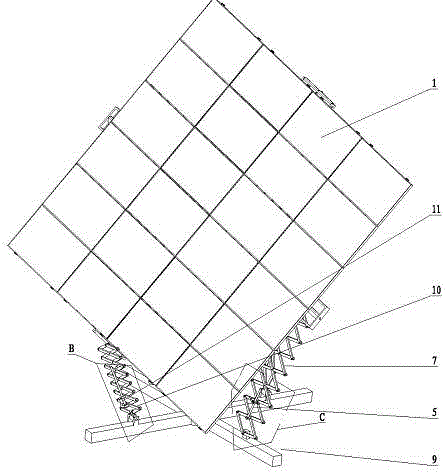

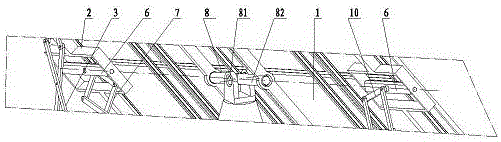

[0033] in figure 1 versus figure 2 In the omnidirectional tracking photovoltaic power generation equipment shown, the component mounting bracket 2 is a rectangular frame steel member, and the photovoltaic module 1 is installed on the component mounting bracket 2 of the rectangular frame steel member, see image 3 , The bottom center of the component mounting bracket 2 is hinged with both ends of the shaft A82 on the cross shaft 8. The shaft B81 and the shaft A82 on the cross shaft 8 intersect perpendicularly to each other, and the length of the shaft B81 is relatively shorter than the length of the shaft A82 to facilitate The component mounting bracket 2 has a relatively large angle range when rotating relative to the axis A82. The two ends of the axis B81 on the cross shaft 8 are hinged on the upright part 91 of the base 9, so that the component mounting bracket 2 is supported on the base through the cross shaft 8. On the upright part 91 of the seat 9, the base 9 includes a upr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com