Method for operating a textile machine, and textile machine for producing rovings

A textile machine, roving technology, used in textiles and papermaking, continuous winding spinning machines, spinning machines, etc., can solve the problems affecting the productivity and time-consuming of textile machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

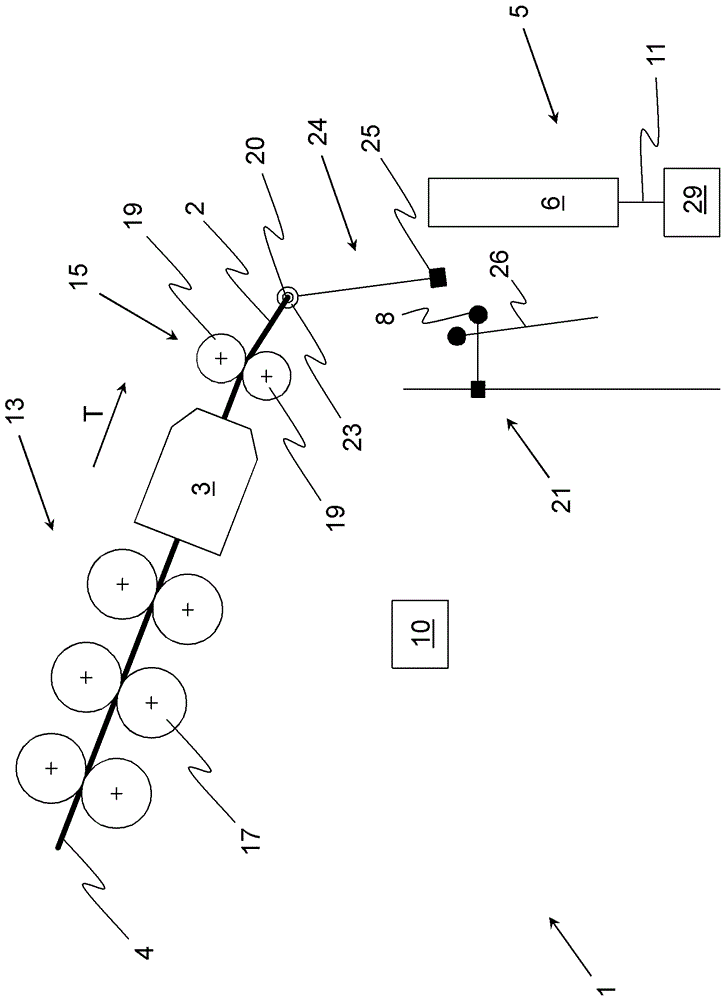

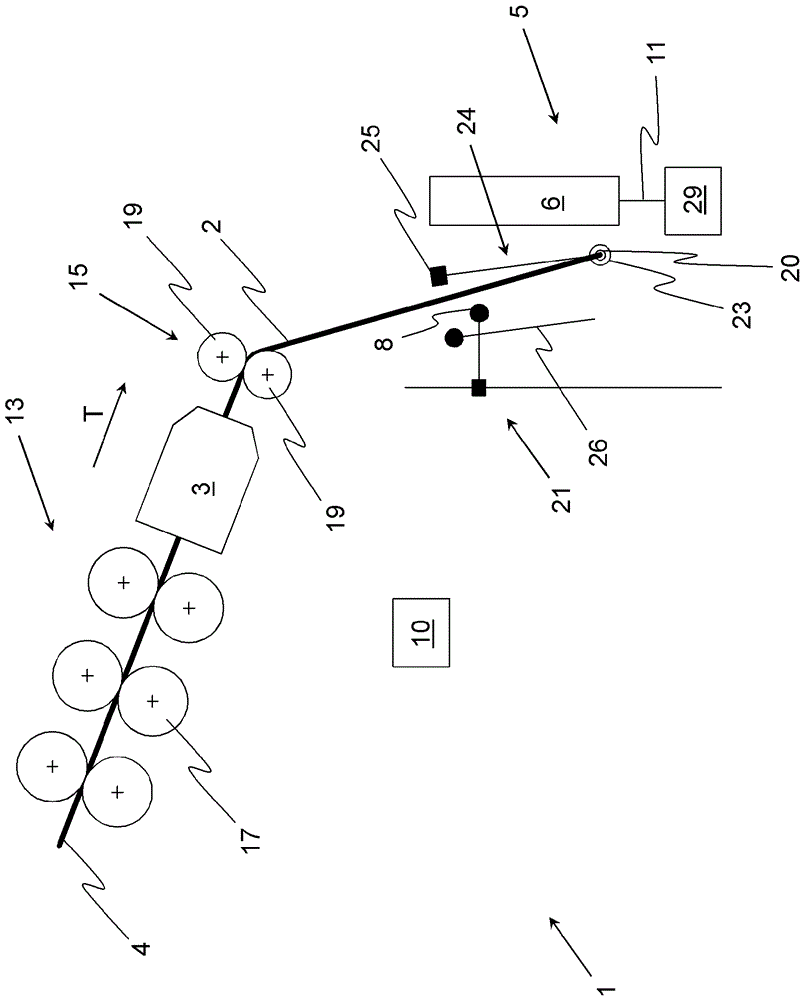

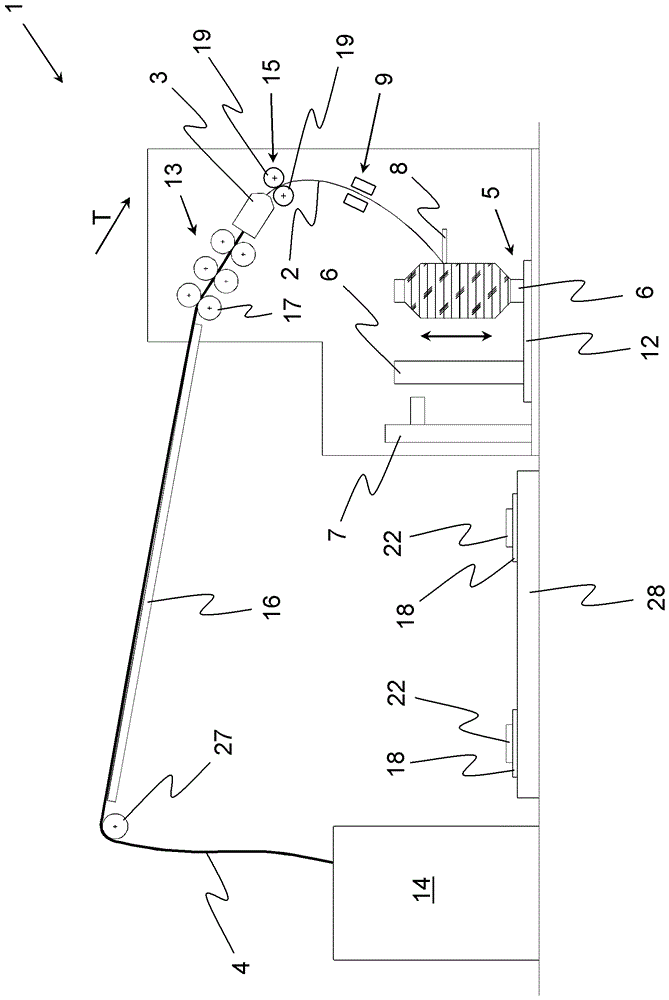

[0032] figure 1 A schematic side view of a textile machine according to the invention in the form of an air-jet spinning machine 1 for producing rovings 2 is shown as an example of such a textile machine. The air-jet spinning machine 1 comprises a drafting system 13 preferably with a plurality of corresponding drafting system rolls 17 (only one of the six drafting system rolls 17 shown is provided with a reference numeral), which is fed For example the fiber bundle 4 in the form of a double drafter sliver.

[0033] The fiber tow 4 typically comes from a container 14, such as a can, and is fed to the drafting system 13, preferably after passing guide rollers 27, via a guide 16, which can be embodied, for example, as an elongated profile.

[0034] The air-jet spinning machine 1 shown also comprises a reinforcement mechanism spaced apart from the drafting system 13 and embodied as an air spinning nozzle 3 with a built-in swirl chamber known from the prior art and therefore not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com