Trail-type straw crushing and returning used plastic film retrieval machine

A straw crushing and traction technology, which is applied to collectors, harvesters, crop processors, etc., can solve the problems that crop straws cannot be crushed and returned to the field, and the stubble in the residual film cannot be effectively separated, so as to facilitate subsequent processing, Reasonable structure and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

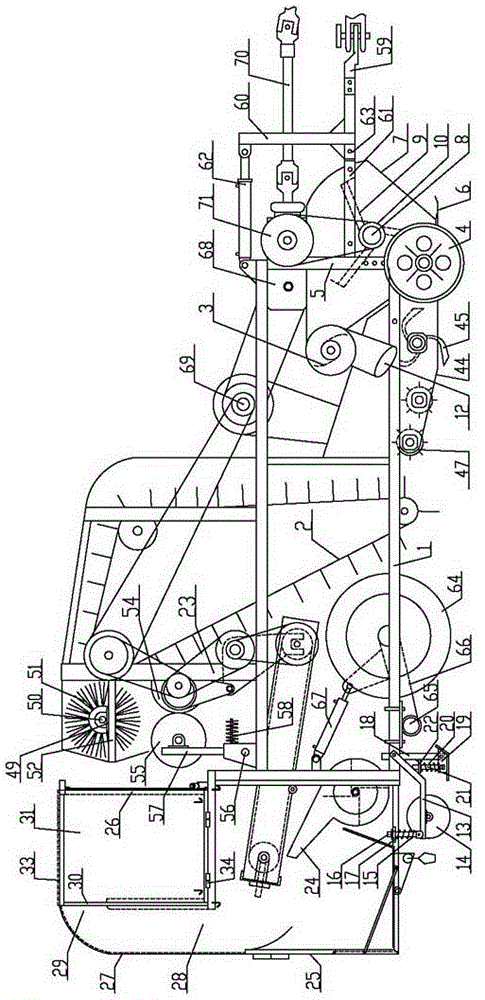

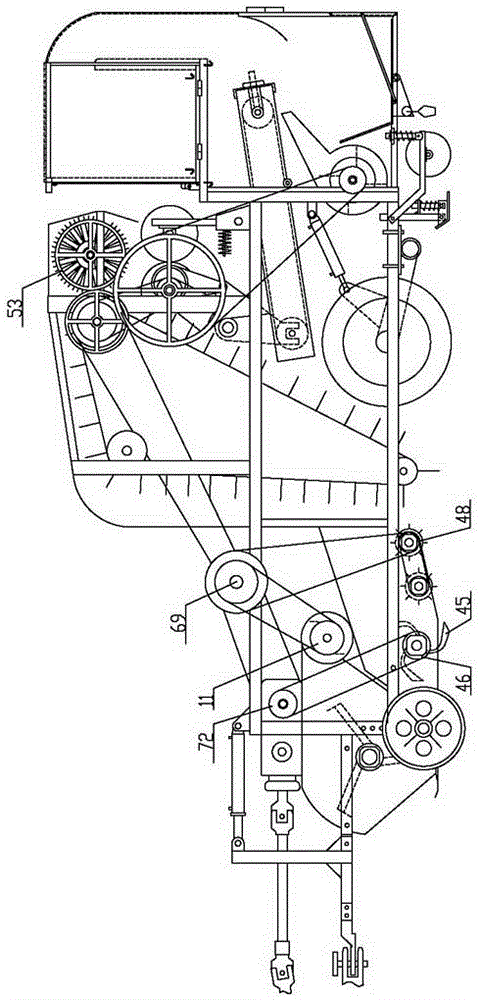

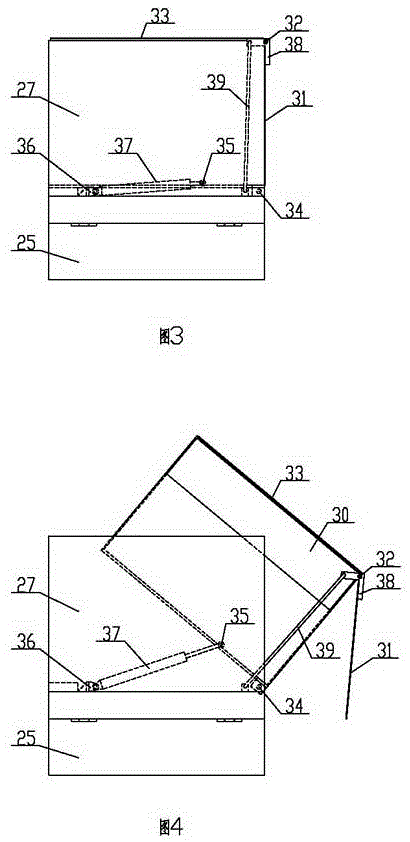

[0036] Embodiment one: as attached figure 1 , 2 , 3, and 4, the residual film collection box 26 is a tilting type residual film tank, and the upper rear end of the tilting type residual film tank is provided with a residual film tank feed port 30 communicated with the guide box outlet 29, and the tilting type The right end of the residual film box is provided with a discharge port with a right end cover 31, and the upper end of the right end cover 31 is hinged on the side tilting type residual film box through the right cover hinge shaft 32, and the top of the side tilting type residual film box has an air outlet and is fixedly installed There is a filter screen 33, and the lower end of the right side of the tilting type residual film box is hinged on the frame 1 through the hinge shaft 34 of the residual film box. The frame 1 in front of the left lower part of the tilting type residual film box is fixed with a residual film tank liquid cylinder seat 36 and is equipped with a...

Embodiment 2

[0037] Embodiment two: as attached Figure 5 , 6 As shown, the residual film collection box 26 is a backward-inclined residual film tank, and the left and right sides of the rear end of the backward-tilted residual film tank are respectively fixed with a residual film tank hinge seat 40 extending backward and downward. Hinged on the top of the stubble collection box 25 rear end by the hinge shaft 34 of the residual film box, the top of the backward inclined type residual film box has an air outlet and a filter screen 33 is fixedly installed, and the middle lower end of the backward inclined type residual film box is fixed with residual film Box piston rod seat 35, on the frame 1 below the front portion of the rear-tilting type residual film box, the residual film tank liquid cylinder seat 36 is fixed and the residual film tank self-unloading cylinder 37 is installed, and the residual film box self-unloading liquid cylinder 37 The upper end of the piston rod is hinged on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com