Corn cooking and drying device

A technology for steaming and drying corn, which is applied in drying, drying machine, drying gas arrangement, etc. It can solve the problems of accelerated corn drying, poor drying efficiency, and low efficiency, and achieves faster water vapor emission and improved drying efficiency. The effect of dry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The utility model is described in further detail below by means of specific embodiments:

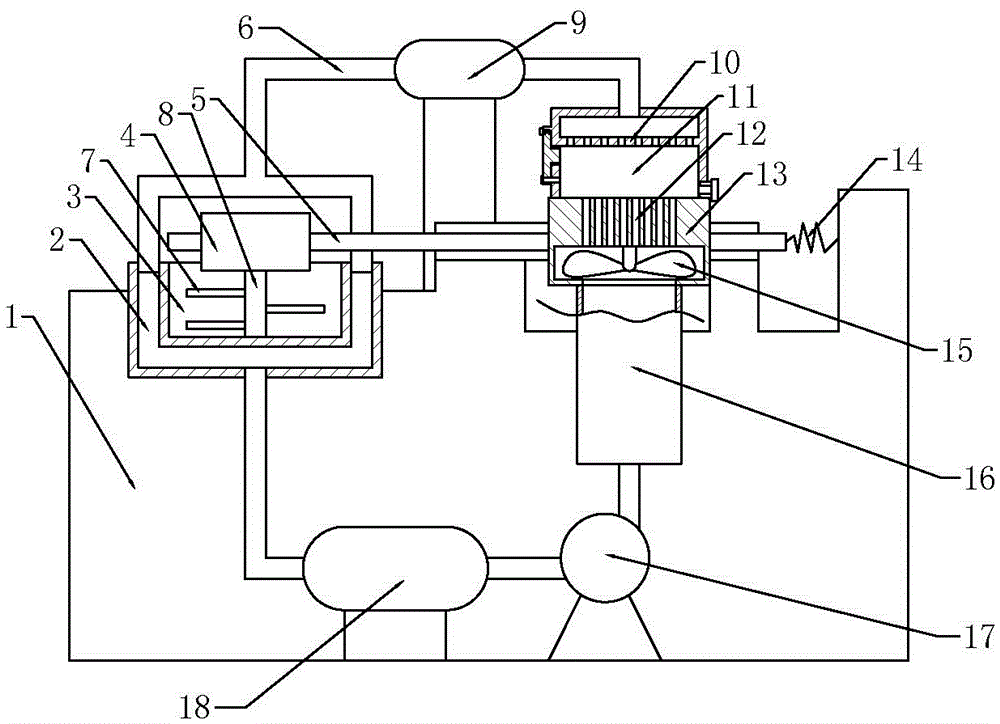

[0019] The reference signs in the drawings of the description include: frame 1, heat exchange cavity 2, hopper 3, gear 4, rack 5, outlet pipe 6, stirring teeth 7, stirring rod 8, filter 9, filter plate 10, Steaming cylinder 11, through hole 12, rotating disk 13, tension spring 14, rotating blade 15, connecting cylinder 16, steam pump 17, steam boiler 18.

[0020] Example figure 1 As shown, a corn cooking and drying device includes a frame 1. A cooking chamber is fixed on the frame 1 by bolts. The cooking chamber is connected with an air inlet pipe and an air outlet pipe 6, and steam is connected between the air inlet pipe and the air outlet pipe 6 in sequence. Pump 17, steam pot 18, drying chamber and filter 9, steam pump 17, steam pot 18, drying chamber and filter 9 are all welded on the frame 1, and the cooking chamber includes cooking cylinder 11 and communicating cylinder 16,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com