Cigarette acceleration device and defective cigarette recovery and processing device

An accelerating device and recycling technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of complex equipment structure, large floor space and high maintenance cost, and achieve reliable theoretical methods, small floor space and high recycling quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

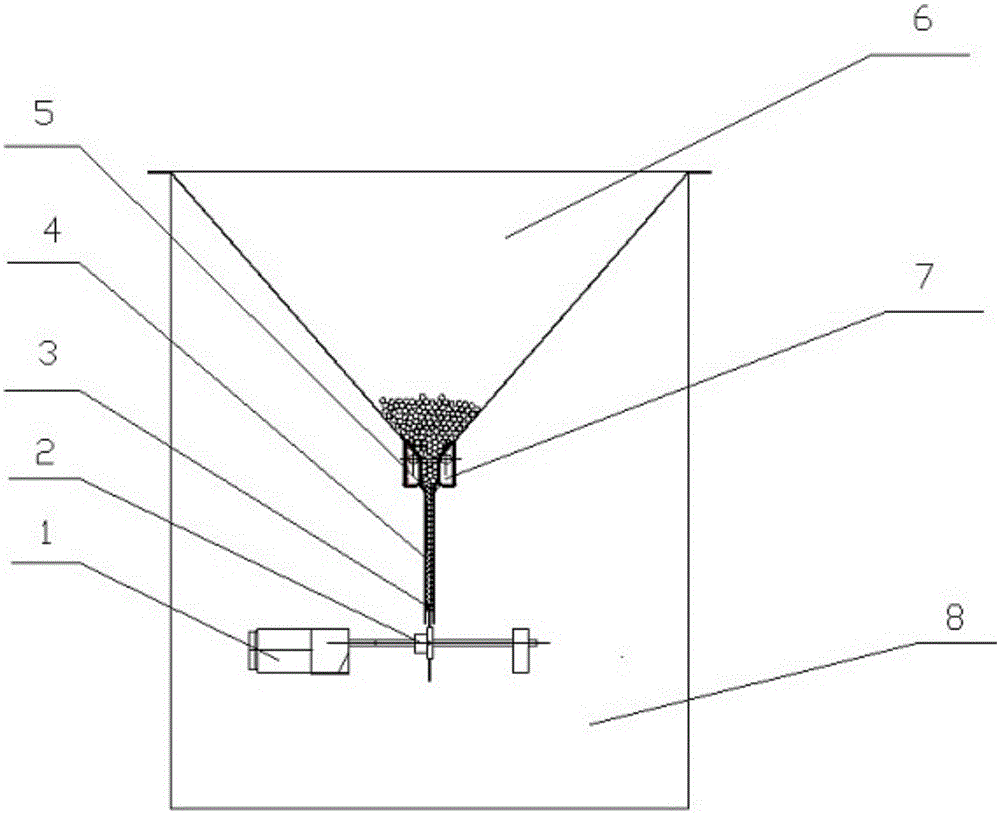

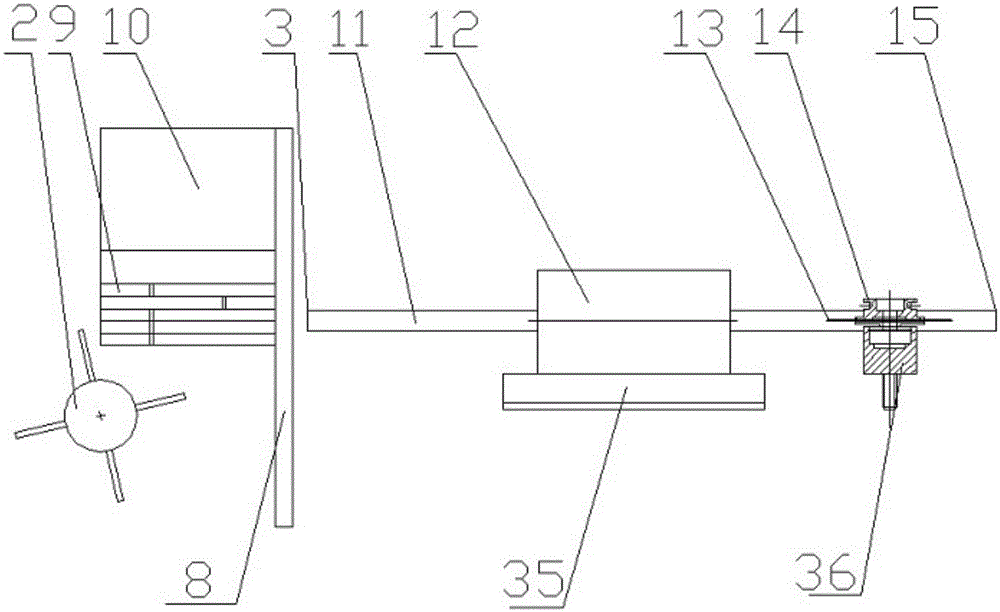

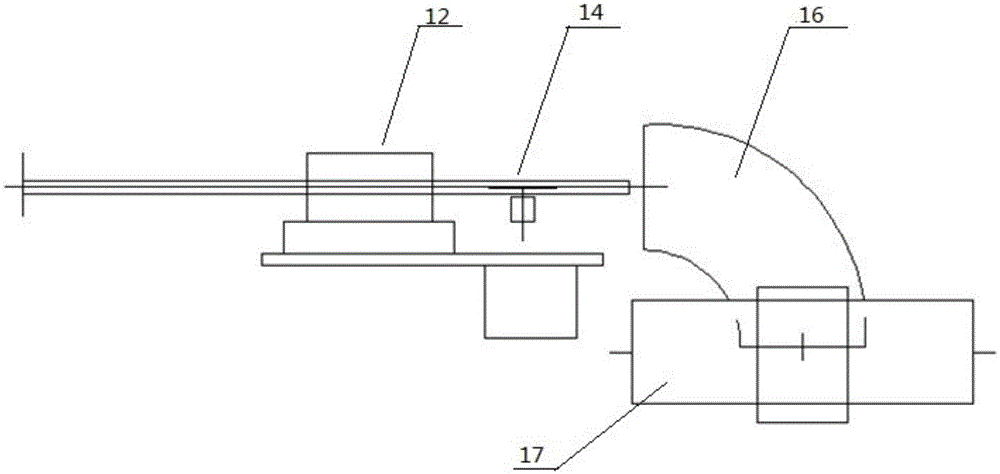

[0055] Embodiment 1: see figure 1 and Figure 4, The bracket 8 is designed with a stainless steel plate, and the width of the lower smoke groove 4 is 7.8mm, which is slightly larger than the diameter of the cigarette stick, so as to ensure smooth feeding. The tobacco rubbing roller 5 and the stirring block 7 are respectively driven by the connecting rod mechanism and the belt on the back of the bracket 8. The stirring block motor eccentric wheel 18 drives the stirring block connecting assembly 19 to make a small reciprocating swing through the connecting rod 23, and the stirring block 7 is connected with the stirring block. The component 19 makes a small reciprocating rotation, and the eccentric wheel 21 of the rubbing roller motor drives the eccentric pulley 20 of the rubbing roller through the connecting rod 23 to make a small reciprocating rotation, and the rubbing roller 5 and the eccentric pulley 20 of the rubbing roller are connected by a toothed transmission belt 22, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com