Air smog purifying device

A technology for purifying devices and air, which is applied in the fields of combination devices, gas treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, low purification efficiency of air purification devices, and high maintenance costs, so as to prolong the service life and ensure the sedimentation of dust. Particles, simple device effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

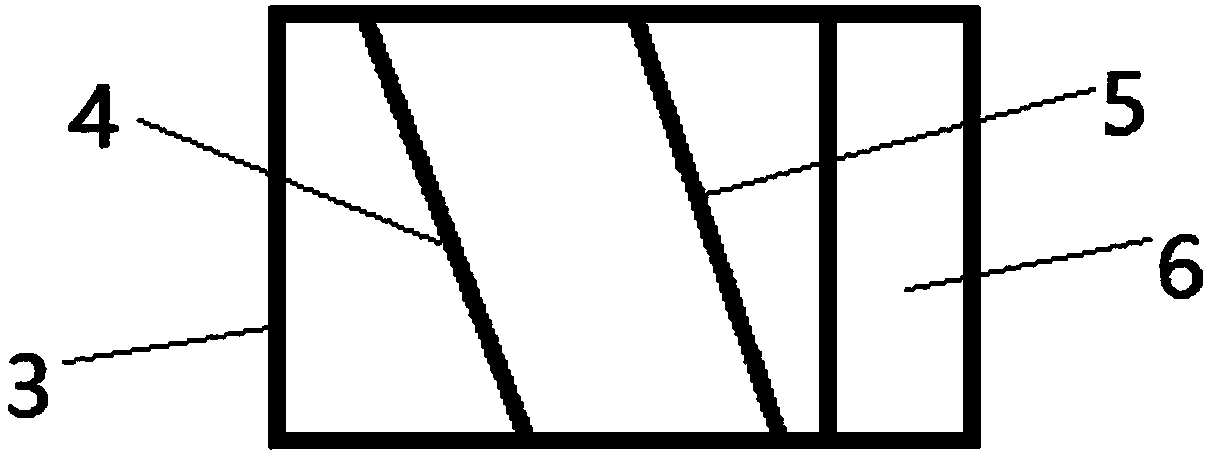

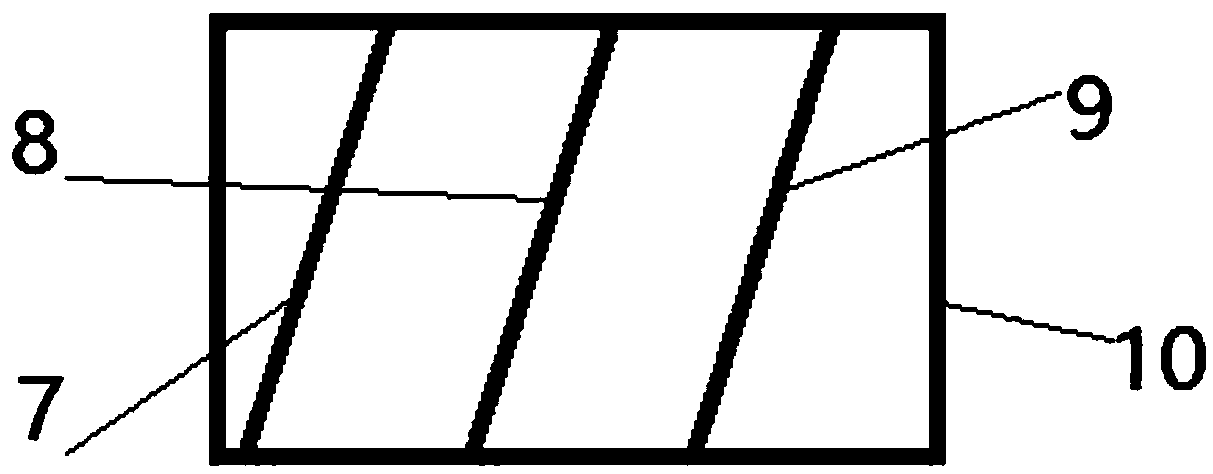

[0032] refer to Figure 1-3 , an air haze purification device, which comprises an air haze primary purification unit 1 and an air haze final purification unit 2, the air haze primary purification unit 1 and the air haze final purification unit 2 in the horizontal direction Arranged in sequence, the air haze primary purification unit 1 includes haze air suction opening 3, coarse adsorption layer 4, charge haze removal layer 5, foam haze removal chamber 6 from outside to inside; the air haze final stage Purification unit 2 includes coating haze removal layer 7, adsorption haze removal layer 8, purification haze removal layer 9 and fresh air discharge outlet 10 sequentially from inside to outside; wherein,

[0033]The coarse adsorption layer 4 has a three-dimensional interlaced network structure, and the pore diameter of the mesh pores is 80 μm. The coarse adsorption layer 4 is an intermediate obtained by blown film molding of polycaprolactone on a molding equipment, and the proc...

Embodiment 2

[0048] refer to Figure 1-3 , an air haze purification device, which comprises an air haze primary purification unit 1 and an air haze final purification unit 2, the air haze primary purification unit 1 and the air haze final purification unit 2 in the horizontal direction Arranged in sequence, the air haze primary purification unit 1 includes haze air suction opening 3, coarse adsorption layer 4, charge haze removal layer 5, foam haze removal chamber 6 from outside to inside; the air haze final stage Purification unit 2 includes coating haze removal layer 7, adsorption haze removal layer 8, purification haze removal layer 9 and fresh air discharge outlet 10 sequentially from inside to outside; wherein,

[0049] The coarse adsorption layer 4 has a three-dimensional interlaced network structure, and the pore diameter of the mesh pores is 120 μm. The coarse adsorption layer 4 is an intermediate obtained by blown film molding of polycaprolactone on a molding equipment, and the pr...

Embodiment 3

[0064] refer to Figure 1-3, an air haze purification device, which comprises an air haze primary purification unit 1 and an air haze final purification unit 2, the air haze primary purification unit 1 and the air haze final purification unit 2 in the horizontal direction Arranged in sequence, the air haze primary purification unit 1 includes haze air suction opening 3, coarse adsorption layer 4, charge haze removal layer 5, foam haze removal chamber 6 from outside to inside; the air haze final stage Purification unit 2 includes coating haze removal layer 7, adsorption haze removal layer 8, purification haze removal layer 9 and fresh air discharge outlet 10 sequentially from inside to outside; wherein,

[0065] The coarse adsorption layer 4 has a three-dimensional interlaced network structure, and the pore diameter of the mesh pores is 100 μm. The coarse adsorption layer 4 is an intermediate obtained by blown film molding of polycaprolactone on a molding equipment, and the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com