A buoy automatic spraying system

A technology of automatic spraying and automatic spraying gun, applied in the direction of spraying device, etc., can solve the problems of easy deflection, color difference spraying efficiency, uneven spraying, etc., to prevent rotational deflection, improve spraying efficiency, and spray evenly and beautifully.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

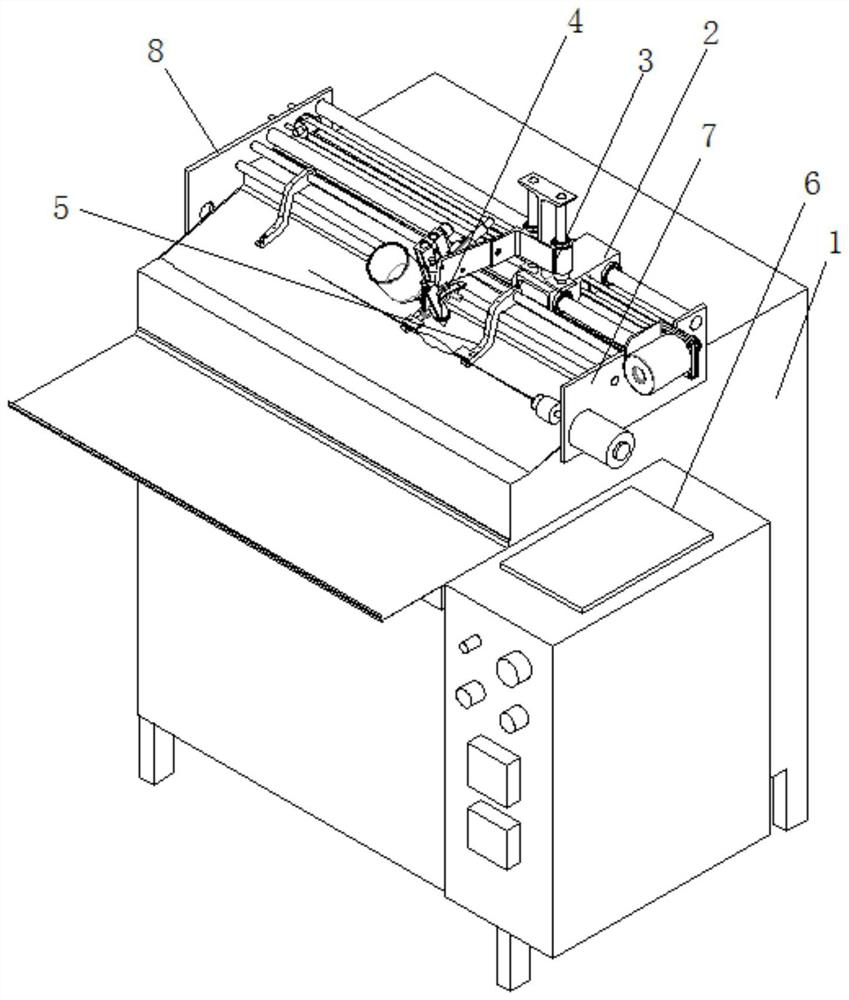

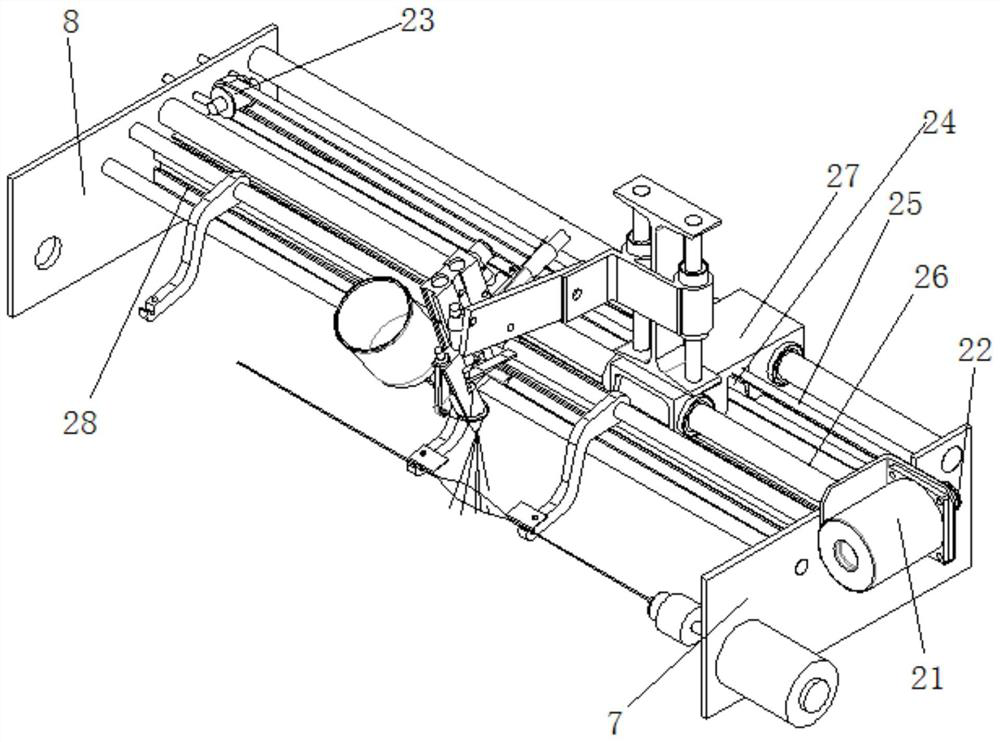

[0040] like Figure 1-Figure 6 As shown, the embodiment of the present invention discloses an automatic buoy spraying system, including a paint recovery processing box 1, a reciprocating motion device 2, a spray gun fixing device 3, an automatic spray gun device 4 and a rotating support device 5, wherein:

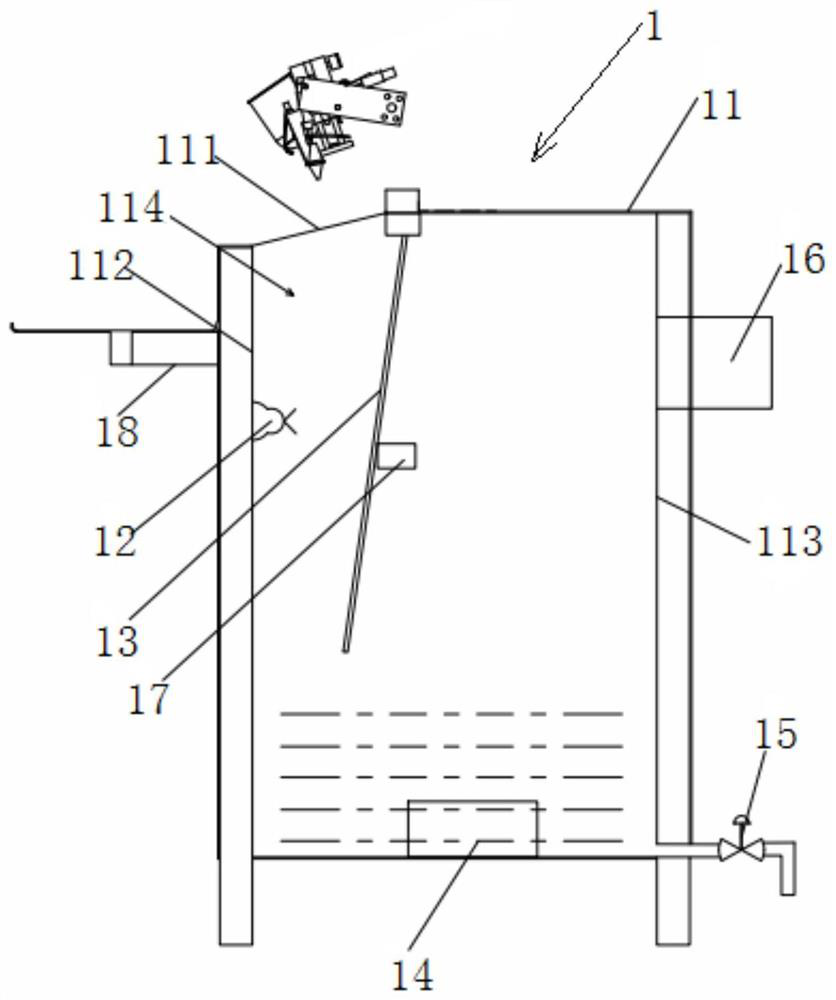

[0041] Paint recycling bin 1, such as figure 2As shown, the paint recovery and treatment box 1 can be set on a fixed plane; it is mainly used to recover the paint that is not sprayed on the buoy to be sprayed during the spraying process. It includes a box body 11, a nozzle 12, a water connection 13, a water pump 14 and a drain valve 15. The upper side of the box body 11 is provided with an opening 111 that communicates the outside of the box body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com