Welding rotary platform

A technology of rotary platform and rotary plate, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not meeting production needs, increasing labor production costs, reducing production efficiency, etc., and achieves low maintenance costs, The effect of optimizing the working site environment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

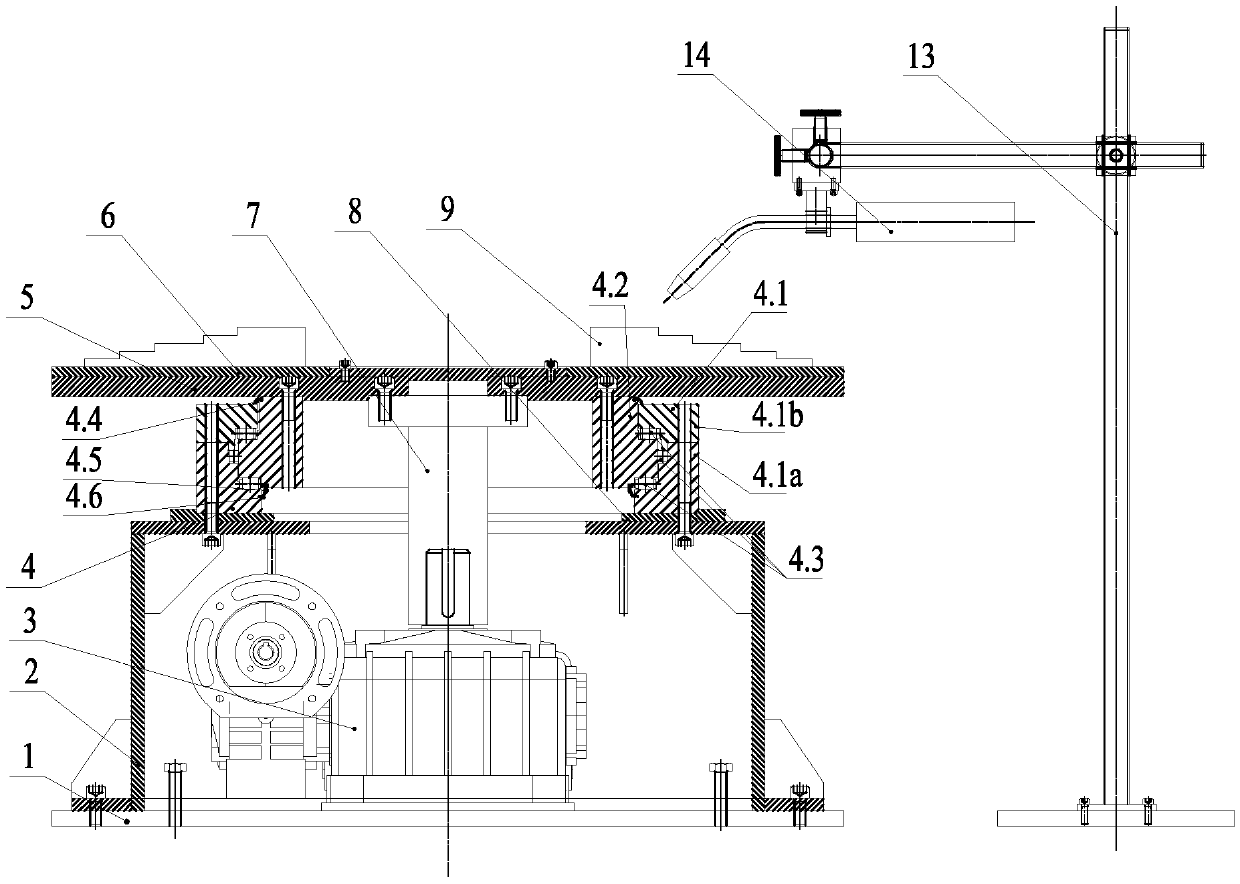

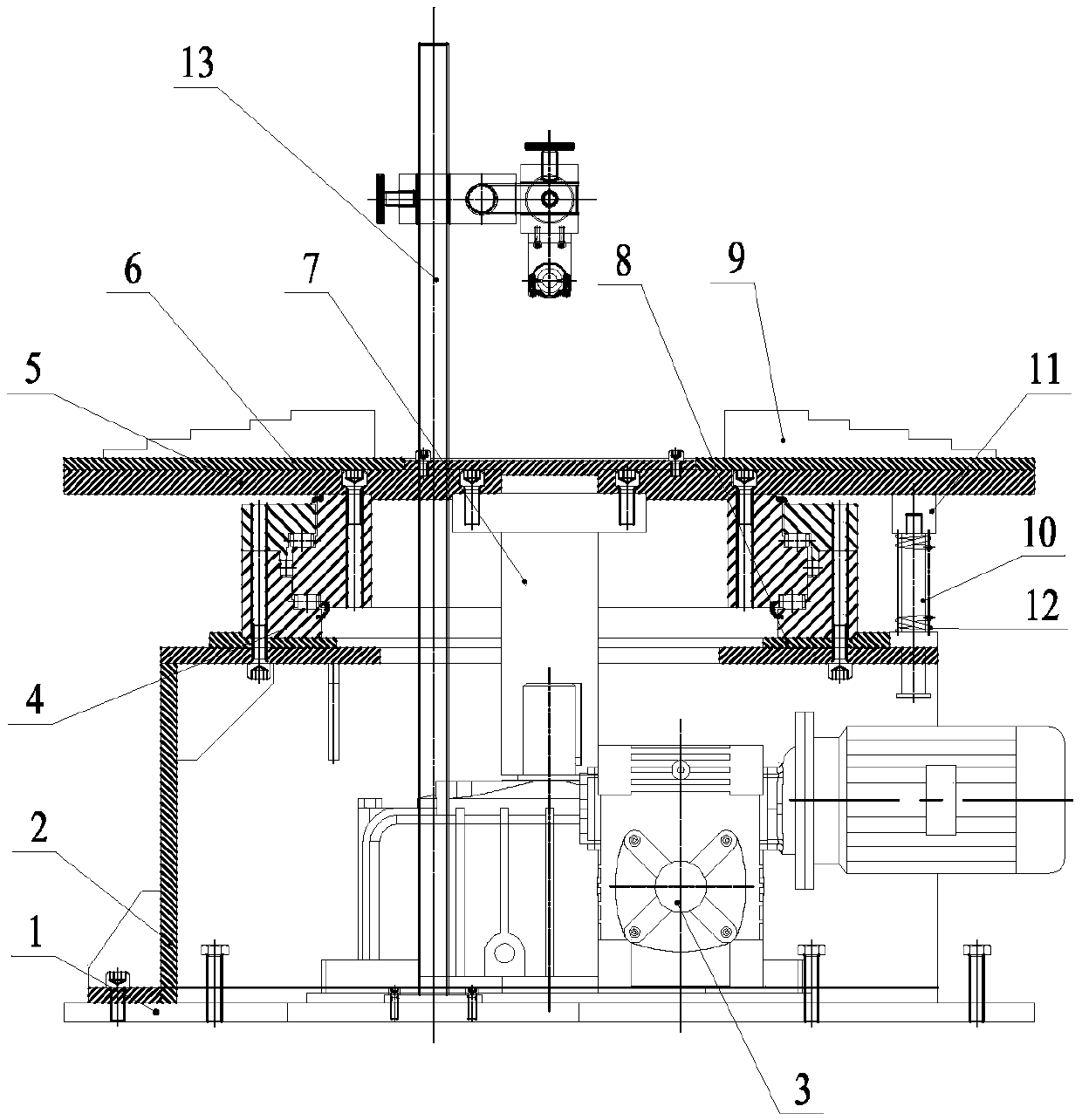

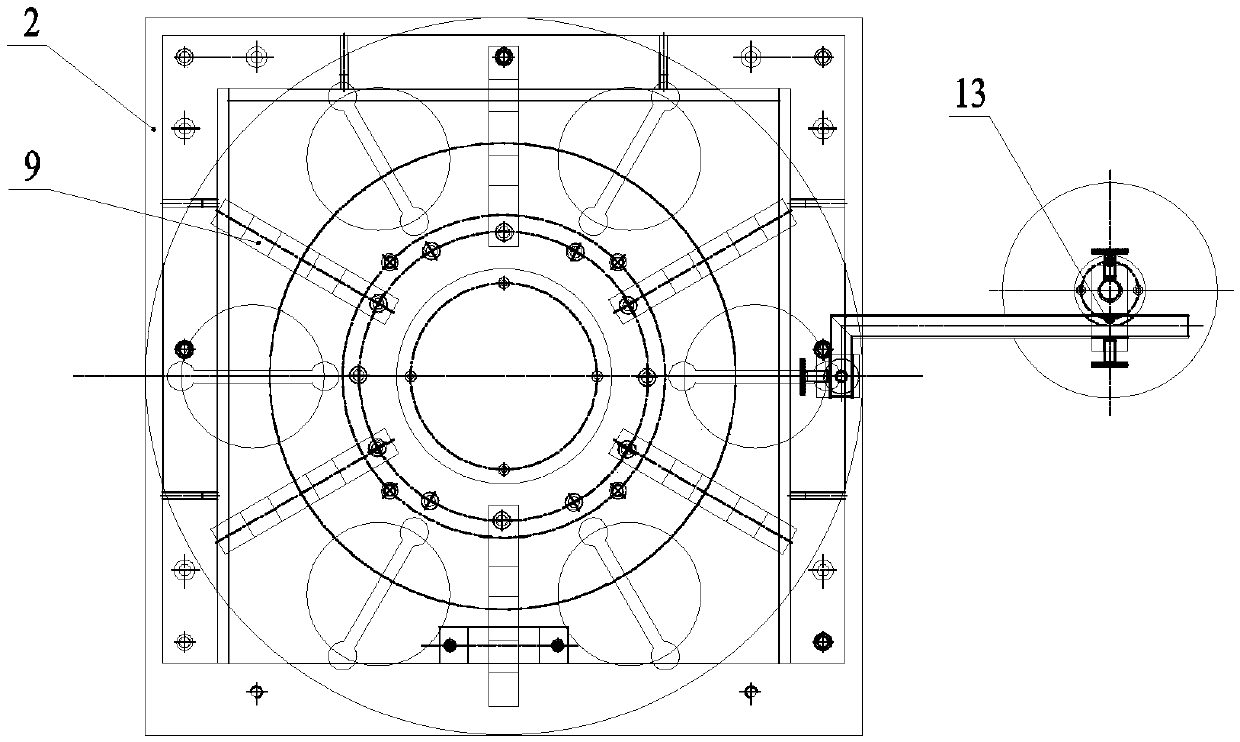

[0018] Such as Figure 1~Figure 3 As shown, the welding rotary platform in the embodiment is mainly composed of a bottom plate 1, a mounting seat 2, a reducer 3, a slewing support 4, a slewing plate 5, a positioning plate 6, a rotating shaft 7, a supporting plate 8, a mold 9, and a pin rod 11 , Plug 10 and spring 12 and so on.

[0019] Such as Figure 1~Figure 3 As shown, in the embodiment of the present invention, the reducer 3 is fixed on the base plate 1, and the mounting seat 2 is covered on the reducer 3 and connected with the base plate 1; the slewing support 4 is fixed on the mounting base 2, and the The revolving plate 5 is connected to the mounting base 2 through the slewing support 4, and the revolving plate 5 can rotate freely; the positioning plate 6 is placed on the revolving plate 5 and fixedly connected with it with screws, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com