Traveling-type solid-liquid separation measuring machine

A technology of solid-liquid separation and metering machine, which is applied in slitting machinery, liquid/fluid solid measurement, measurement capacity, etc., can solve the problems of low solid particle recovery rate, solid particle loss, long time consumption, etc., to reduce labor intensity. , The equipment operates with low noise and improves the effect of the on-site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

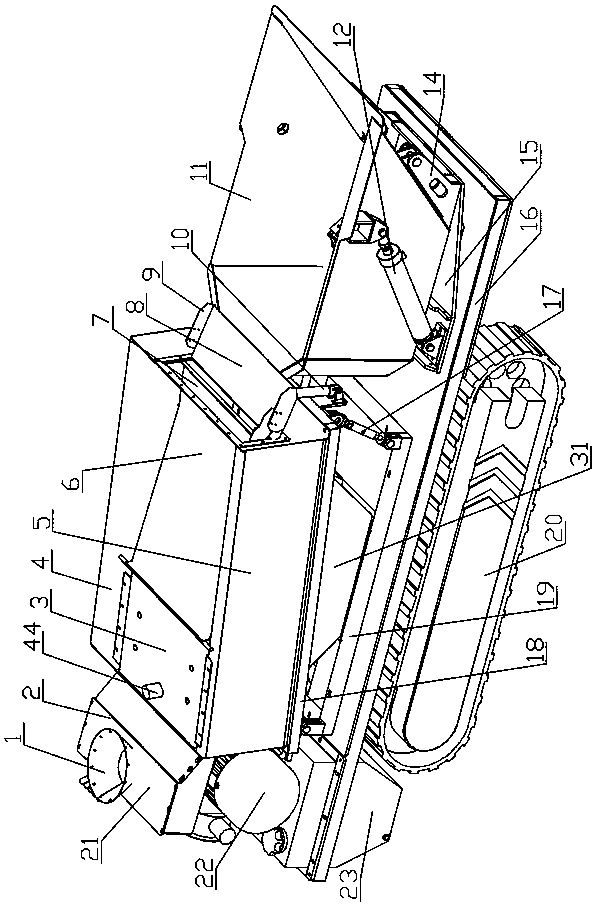

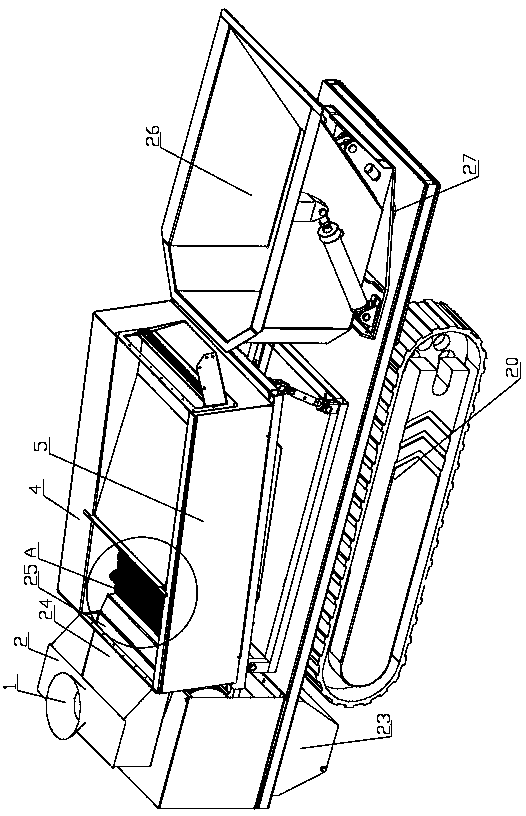

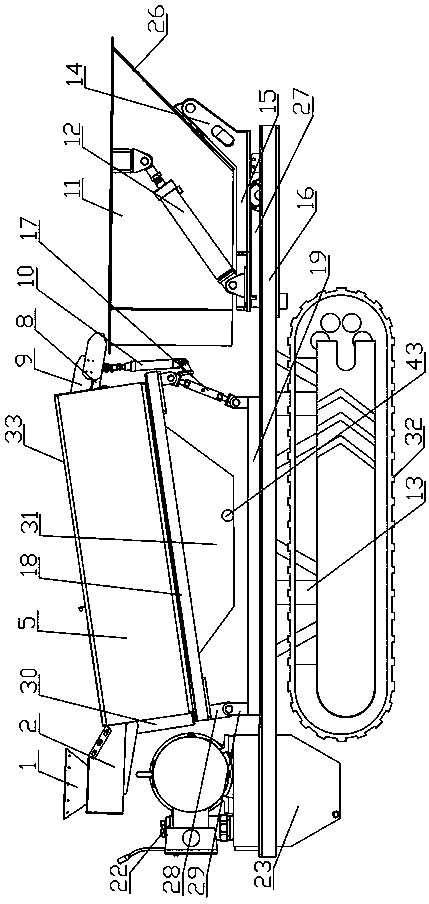

[0035] like Figure 1-8 Shown: a walking type solid-liquid separation metering machine, including a car body platform 16, a moving mechanism 20 arranged below the car body platform 16, a separation mechanism 33 arranged in the middle of the car body platform 16, and a separation mechanism 33 arranged on one side The slag feeding mechanism 21, the rotating mechanism 27 arranged at one end of the car body platform 16, and the self-unloading mechanism 26 arranged on the rotating mechanism 27;

[0036] Described separation mechanism 33 comprises box body 5, and several water filter dividers 34 are vertically evenly arranged in described box body 5, and the two ends of described water filter divider 34 are respectively provided with feeding port 25 and the box body 5. Outlet 7, several bearings 36 are evenly arranged on both sides of the box body 5, and a rotating shaft 37 is arranged between the oppositely arranged bearings 36, and a through hole for the rotating shaft to pass is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com