Automatic screening instrument for automobile engine blank caps

An automobile engine and automatic screening technology, which is applied in sorting and other directions, can solve problems affecting the safety of vehicles and personnel, manual inspection, large manpower, material resources, etc., and achieve the effects of improving efficiency, ensuring accuracy, and ensuring pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

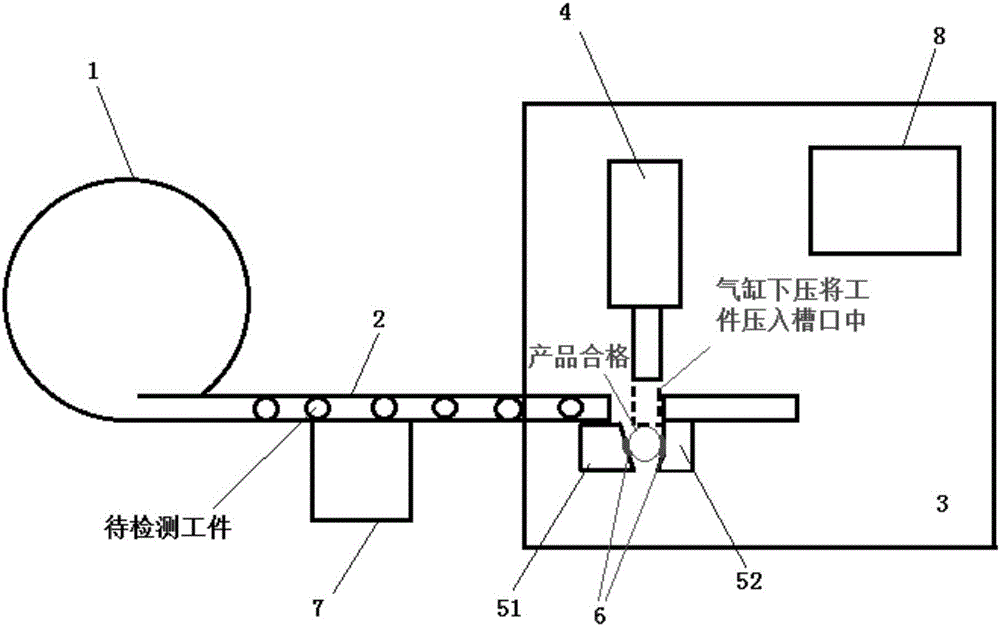

[0022] Such as figure 1 As shown, an automatic screening instrument for stuffy covers of automobile engines is used to automatically screen stuffy covers whose diameters meet the size requirements. Mechanism and controller, the detection mechanism includes a detection cylinder 4, a first fixed stop 51 and a second fixed stop 52, and the first fixed stop 51 and the second fixed stop 52 are oppositely arranged to form a "V"-shaped detection groove A pair of opposite detection blocks 6 are arranged on the inner wall of the detection groove, and a contact sensor connected to the controller is arranged on the detection block 6. One end of the guide rail 2 is connected with the centrifugal vibrating hopper 1, and the other end is arranged on the detection groove. At the entrance, the top of the detection cylinder 4 is set opposite to the entrance of the detection groove;

[0023] The automatic screening instrument also includes a shape detection mechanism. The shape detection mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com