Universal supporting module used for barrel stamping die

A stamping die and support module technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long time period, low cost performance, and lack of versatility of support blocks, and achieve good assembly performance, simple structure, Good interchangeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

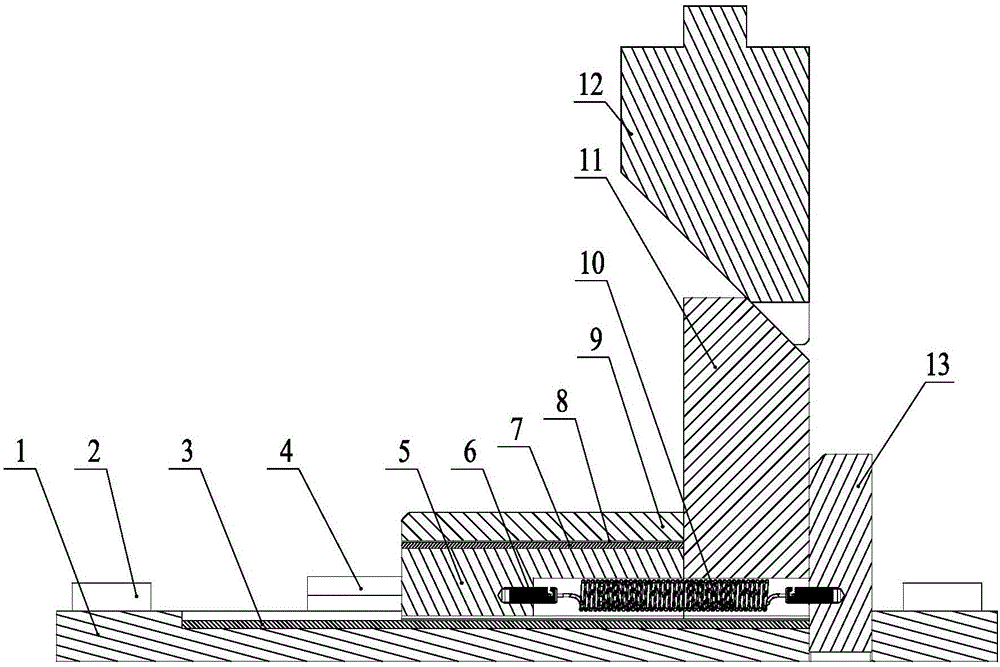

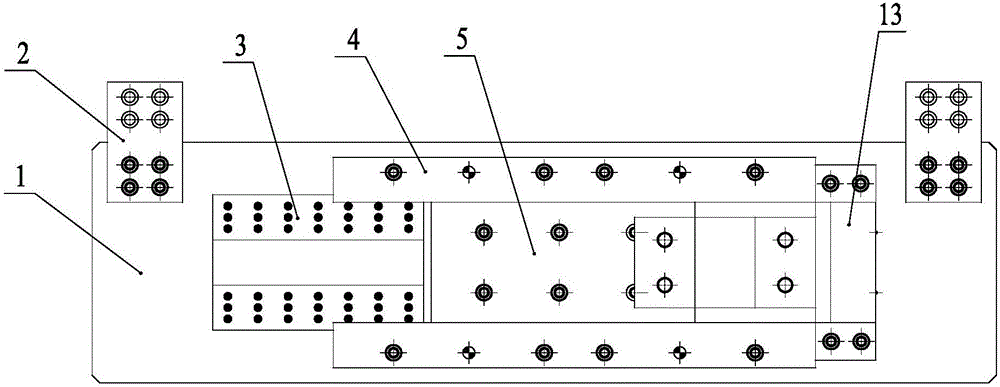

[0021] As shown in the figure: the general-purpose support module for the cylinder stamping die in the embodiment mainly consists of a lower base plate 1, a guide block 4, a lower support block 5, an upper support block 9, a tension spring 10, a lower wedge 11, Upper inclined wedge 12 and block 13 etc. are formed.

[0022] like figure 1 , figure 2 As shown, two guide blocks 4 arranged horizontally and horizontally are respectively installed on the front and rear sides of the lower base plate 1. The lower support block 5 is placed on the lower base plate 1 and placed between the two guide blocks 4. The lower support block 5 can be placed on the lower base plate 1. The two pieces of guide block 4 slide left and right under the guidance; the upper support block 9 is installed on the top of the lower support block 5 and can be disassembled freely; The upper inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com