A Method for Isothermal Die Forging Process Trajectory Planning Oriented to the Target Grain Structure of Forgings

A technology of isothermal die forging and process, applied in the field of warm die forging, can solve the problems such as the inability to guarantee the quality of forgings, the inability to measure the internal microstructure of the non-linear rheological properties of forging blanks online, and the inability to accurately control the grain structure of forgings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

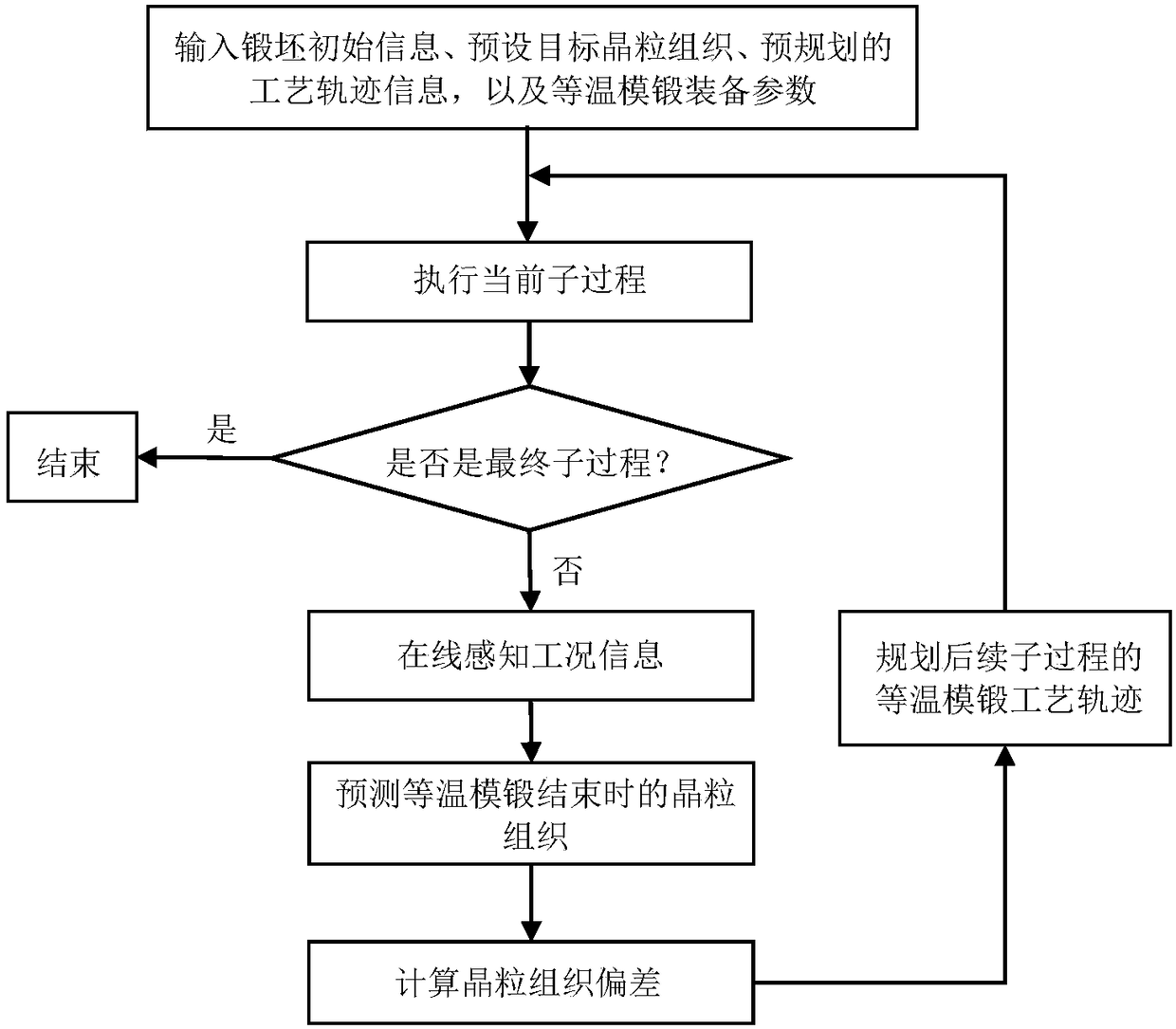

[0056] The present invention is an isothermal die forging process track planning method for forging target grain structure, and its flow chart is as follows figure 1 shown. Taking the isothermal die forging of the I-stage turbine disk of a certain type of engine as an example, the implementation details of the die forging process trajectory planning method involved in the present invention will be introduced in detail below.

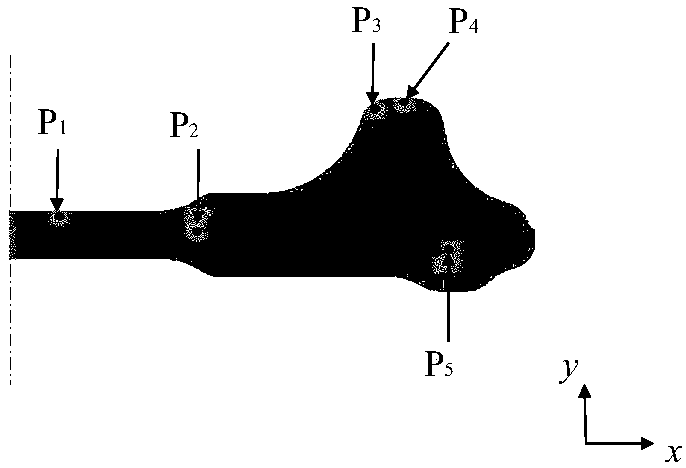

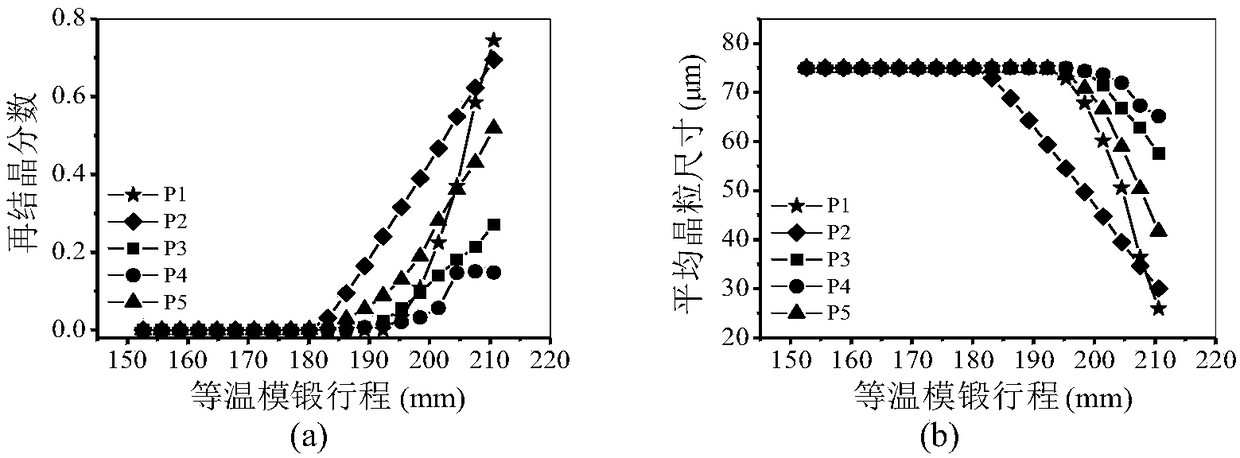

[0057] figure 2 Shown is a two-dimensional axial cross-sectional schematic diagram of the I-stage turbine disk of a certain type of engine. The base material of the turbine disk is GH4169 alloy. Select a series of key parts located in the hard-to-deform region of the turbine disk, P 1 ,P 2 ,P 3 ,P 4 and P 5 , whose coordinates are shown in Table 1. First, the isothermal die forging forming of the turbine disk i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com