Boxboard based on high-density oriented strand board and processing method thereof

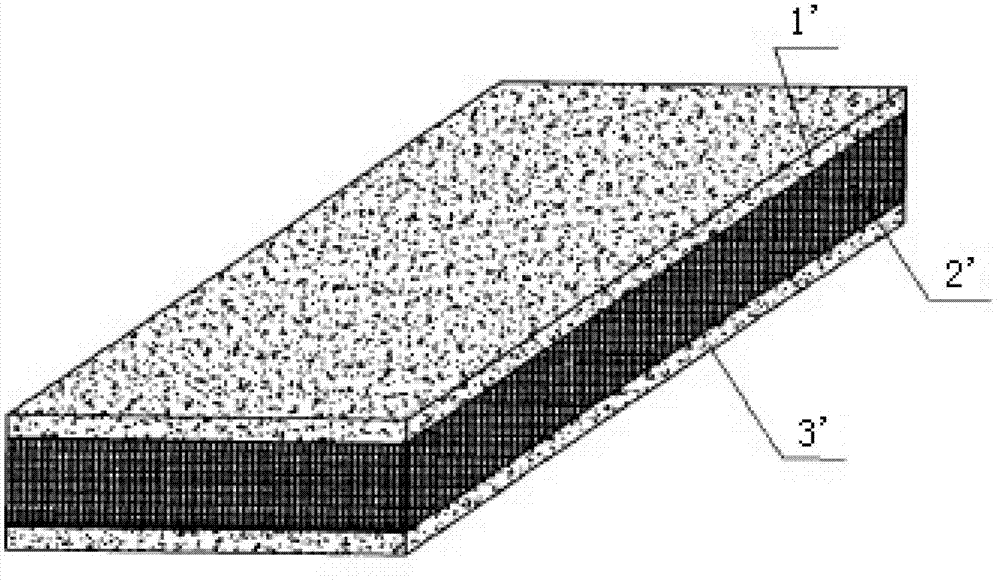

The technology of an oriented strand board and a processing method, which is applied in the field of wood processing, can solve the problems of low product processing qualification rate, not easy to excessive pressure, affecting the strength of particle board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

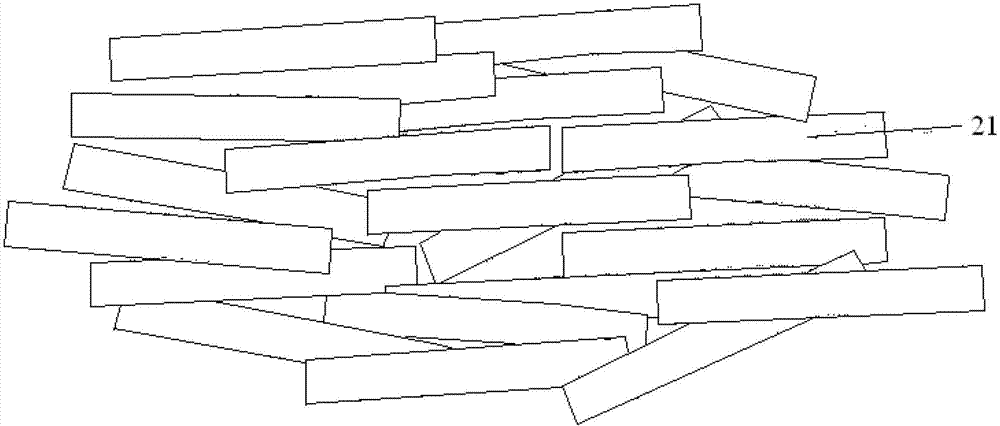

[0061] The present invention has no special limitation on the preparation method of the shavings, and the technical solution for preparing the shavings well-known to those skilled in the art can be adopted. The present invention preferably adopts the shaving machine with the model of CARMANAH 34 / 114 BLOCK DISC FLAKER (FORMERLY CAE) SOB / SERIAL NO.150-83 to produce the shavings of the above-mentioned size. In the process of producing the above-mentioned shavings, the length of the feed wood segment is preferably is 800 mm, and the diameter is preferably 100 mm to 600 mm.

[0062] After obtaining the shavings that can be processed in the next step, the shavings are mixed with the adhesive to obtain the glue-mixed shavings. The present invention has no particular limitation on the mass ratio of the shavings and the adhesive, and the mass ratio of the shavings and the adhesive well known to those skilled in the art can be used.

[0063] The research of the present invention shows ...

Embodiment 1

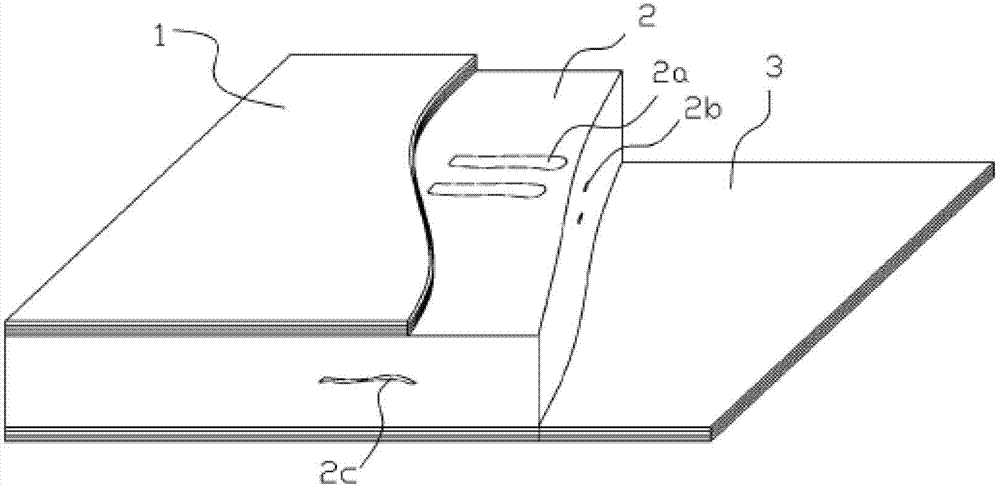

[0084] Provide the shavings that are 120mm in length, 20mm in width and 0.5mm in thickness, spray and atomize the adhesive on the surface of the shavings according to the mass ratio of the shavings and the adhesive of 100:18, and complete the sizing process for the shavings; The shavings evenly mixed with the adhesive are arranged in layers along the wood grain direction of the shavings by a paving machine, and the shavings are paved to obtain a slab; the obtained slab is pre-pressed and then hot-pressed, and the pressure of the hot-pressing is 2.9MPa ~3.3MPa, the temperature is 135℃~145℃, and the time is 1150s~1300s to obtain high-density oriented strand board.

[0085] The present invention carries out the performance test of the obtained high-density oriented strand board, the density is measured according to the method recorded in 4.2 in the national standard GB / T17657-1999, and the moisture content is measured according to the national standard GB / T 17657-1999 "Physical an...

Embodiment 2

[0088] Provide shavings with a length of 110mm, a width of 15mm, and a thickness of 0.45mm, spray the adhesive on the surface of the shavings according to the mass ratio of the shavings and the adhesive of 100:18, and complete the sizing process for the shavings; mix the obtained shavings with the adhesive evenly The wood shavings are stacked and arranged mutually oriented along the wood grain direction of the shavings by a paving machine, and the shavings are paved to obtain a slab; the obtained slab is pre-pressed and then hot-pressed, and the pressure of the hot-pressing is 2.7MPa~3.1MPa , the temperature is 130° C. to 140° C., and the time is 1300s to 1450s to obtain a high-density oriented strand board.

[0089] The present invention carries out the performance test of the obtained high-density oriented strand board, the density is measured according to the method recorded in 4.2 in the national standard GB / T17657-1999, and the moisture content is measured according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Air dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com