Glass mold cavity polishing device

A technology for polishing devices and glass molds, applied in grinding/polishing equipment, manufacturing tools, grinding machines, etc., can solve problems such as different roughness and poor flatness of glass, and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

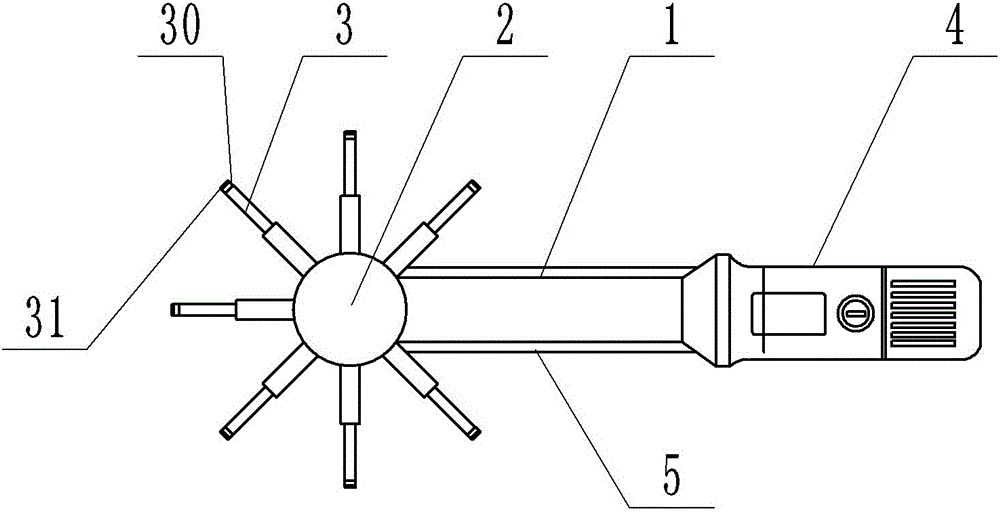

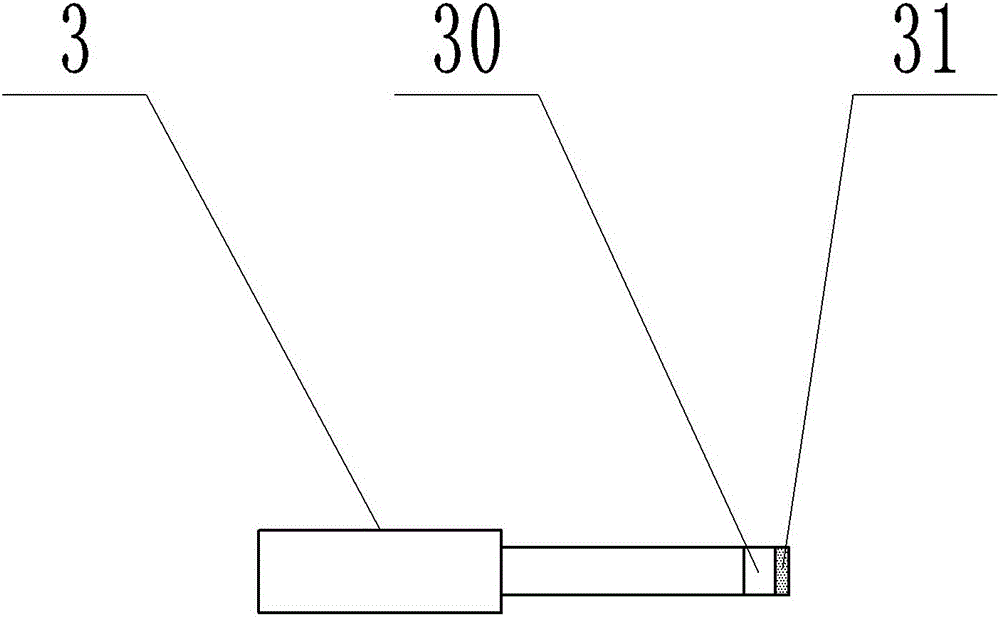

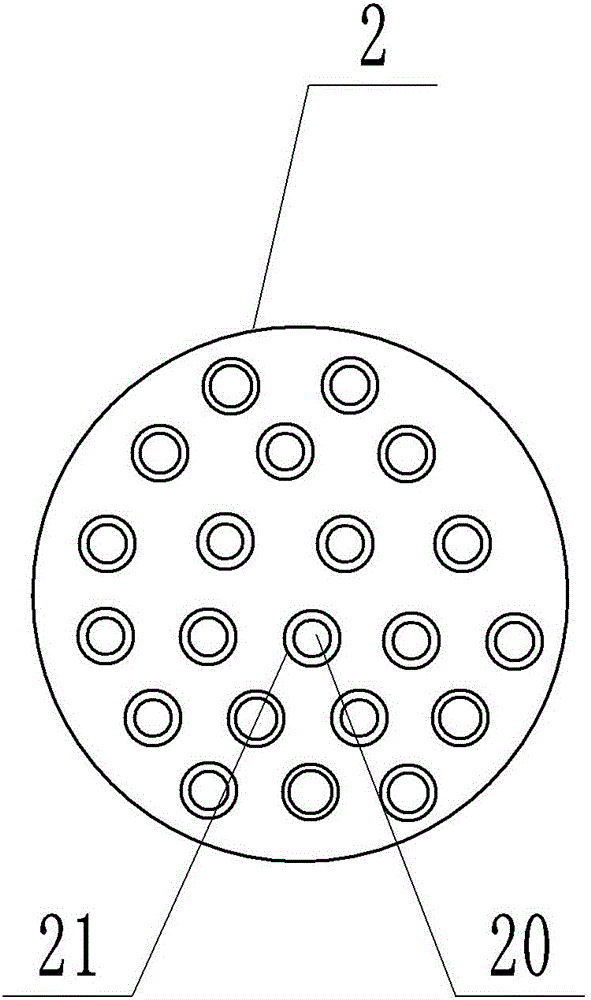

[0016] The reference signs in the accompanying drawings of the description include: rotating shaft 1, spherical body 2, shaft insertion hole 20, sealing gasket 21, telescopic rod 3, polishing pad 30, abrasive layer 31, motor 4, rubber sleeve 5.

[0017] The embodiment is basically as attached figure 1 As shown, the glass mold cavity polishing device includes a rotating shaft 1, such as image 3 As shown, one end of the rotating shaft 1 is hinged with a spherical body 2, the other end of the rotating shaft 1 is threadedly connected with a spline sleeve, the outer side of the rotating shaft 1 is covered with a rubber sleeve 5, and the spherical body 2 is provided with several shaft insertion holes 20, such as figure 2 As shown, several telescopic rods 3 are also included, and several telescopic rods 3 are evenly distributed in the circumferential direction of the spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com