A kind of single crystal diamond abrasive grain and preparation method thereof

A single crystal diamond and abrasive grain technology, which is applied in chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve the problem of low self-sharpening, few contact points, and large concave on the surface of single crystal diamond particles. pits and other problems, to achieve the effect of shortening the process cycle, high self-sharpening, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment provides a kind of single crystal diamond abrasive grain, and its preparation method comprises the following steps:

[0056] 1) Take 4g of single crystal diamond with a particle size of 15-25μm and 16g of iron powder with a particle size of 1-3μm according to the proportion, put them into a closed reaction furnace and mix them evenly;

[0057] 2) press the mixture obtained in step 1) into a sheet with a thickness of 3.73mm at a pressure of 6Mpa with a press;

[0058] 3) Place the sheet obtained in step 2) into a vacuum furnace for heat treatment at 950° C. for 3 hours, wherein the vacuum degree in the vacuum furnace is 4 Pa; then cool naturally to room temperature; then break into small pieces;

[0059] 4) Put 10 g of the cooled and broken flakes obtained in step 3) into a sulfuric acid solution (formed from 120 ml of concentrated sulfuric acid and 500 ml of water) for 4 hours at a treatment temperature of 56° C.; become a powdery solid); incline...

Embodiment 2

[0062] The present embodiment provides a kind of single crystal diamond abrasive grain, and its preparation method comprises the following steps:

[0063] 1) Take 4g of single crystal diamond with a particle size of 5-10μm and 16g of iron powder with a particle size of 1-3μm according to the ratio, put them into a closed reaction furnace and mix them evenly;

[0064] 2) Press the mixture obtained in step 1) into a sheet with a thickness of 4.10mm at a pressure of 3Mpa with a press;

[0065] 3) Put the flakes obtained in step 2) into a vacuum furnace for heat treatment at 900° C. for 3 hours under the protection of a nitrogen atmosphere, wherein the vacuum degree in the vacuum furnace is 6 Pa; then cool naturally to room temperature; then break into small pieces;

[0066] 4) Put 10 g of the cooled and broken flakes obtained in step 3) into 600 ml of sulfuric acid solution with a mass concentration of 30% and treat them at room temperature for 3 hours; For the supernatant, tran...

Embodiment 3

[0069] The present embodiment provides a kind of single crystal diamond abrasive grain, and its preparation method comprises the following steps:

[0070] 1) According to the ratio, take 2g of single crystal diamond with a particle size of 20-40μm and 8g of iron powder with a particle size of 3-5μm, put them into a closed reaction furnace and mix them evenly;

[0071] 2) Press the mixture obtained in step 1) into a sheet with a thickness of 2.08mm at a pressure of 3Mpa with a press; the subsequent processing steps are the same as in Example 1.

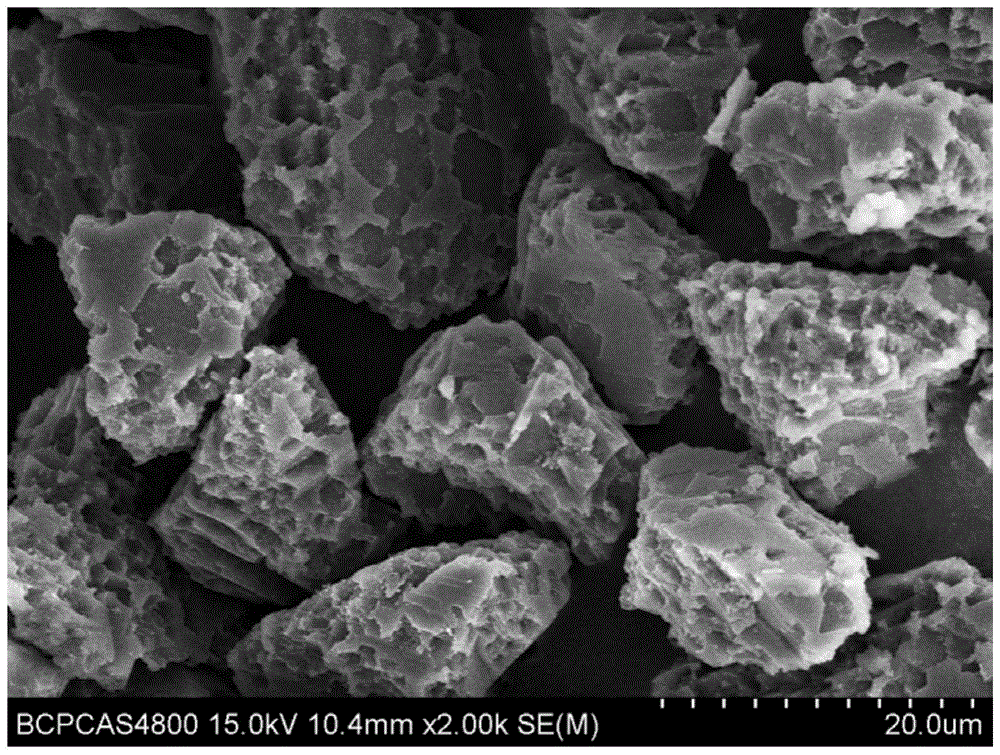

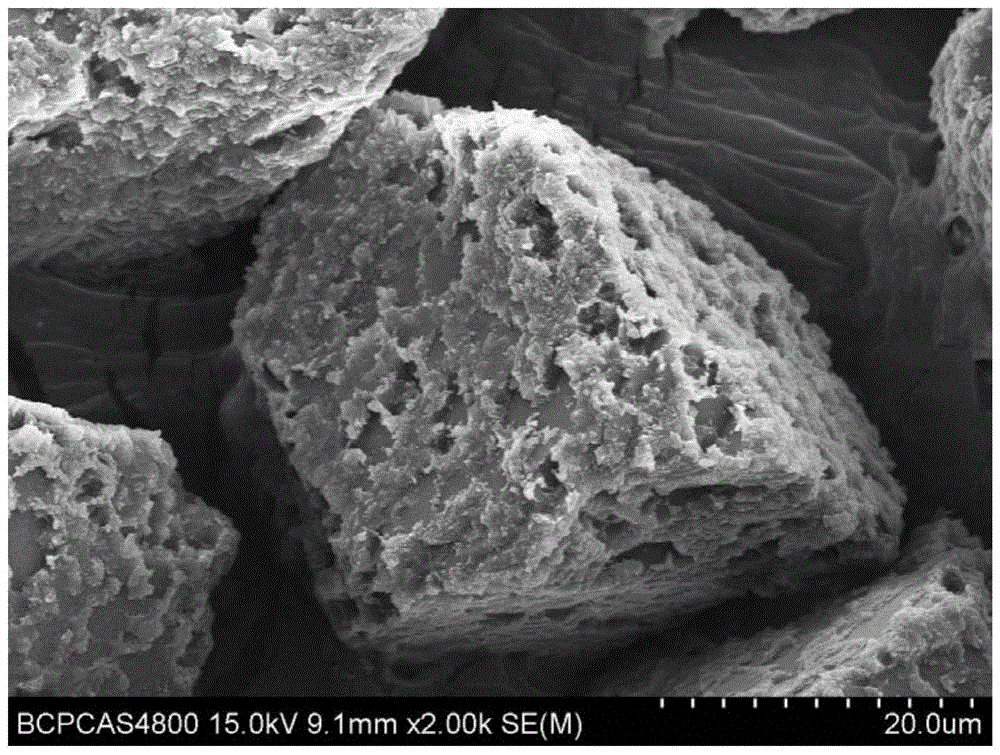

[0072] The prepared single crystal diamond abrasive grain density of the present embodiment is 3.81g / cm 3 , the surface presents a unique rough appearance, and the median particle size (D50) is 28.54 μm; its SEM (scanning electron microscope) picture is as follows image 3 As shown, it can be seen that the surface of the single crystal diamond abrasive grain presents a unique rough shape, the surface is layered, uneven, and there will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com