Treatment method for improving wood weather resistance and amphiphobic performance without pollution

A treatment method and non-polluting technology, applied in wood treatment, electric wood treatment, wood treatment details, etc., can solve the problems of long cycle time, toxicity of organic raw materials, etc., and achieve the effect of improving efficiency and shortening sputtering treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

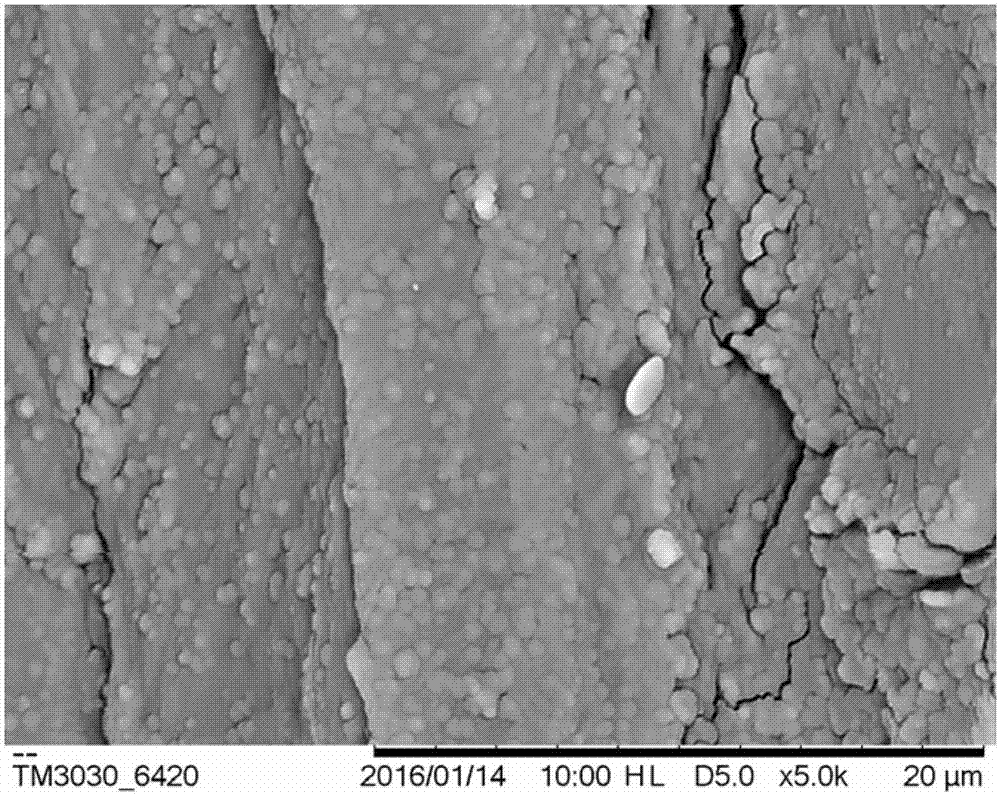

[0023] Specific implementation mode one: the treatment method of this embodiment pollution-free improving wood weather resistance is implemented according to the following steps:

[0024] 1. Put the wood in the lumen of the plasma cleaner, evacuate the lumen to a vacuum, inject argon gas, turn on the power and perform plasma cleaning in the glow state to obtain the cleaned wood;

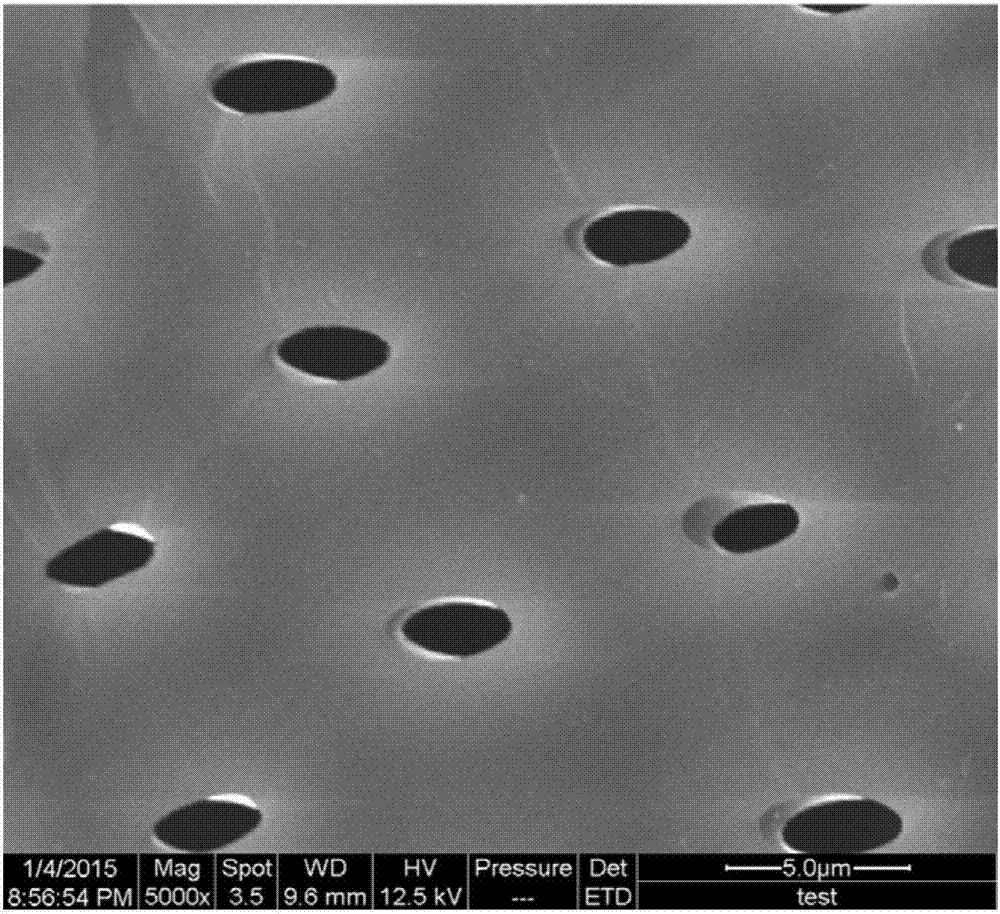

[0025] 2. Put the cleaned wood into the magnetron sputtering apparatus, pump it into a vacuum, and then introduce oxygen, turn on the radio frequency power supply with titanium element, and pre-sputter for 1 to 2 minutes to obtain pre-sputtered wood;

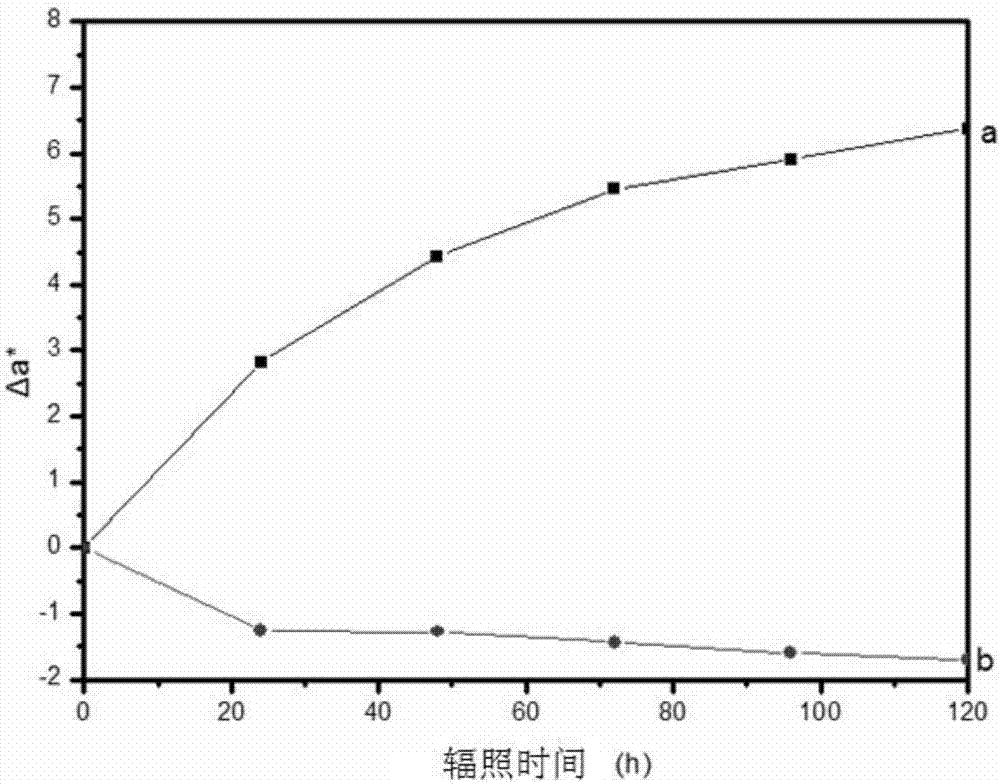

[0026] 3. After the glow of titanium elemental substance is oxidized into titanium dioxide ions, open the cover door of the magnetron sputtering target head, firstly in a vacuum of 8.3×10 -6 MPa~1.0×10 -5 MPa, the power is 300-400W, the oxygen flow rate is 5-7sccm, and the argon flow rate is 9-13sccm, and the particle sputtering treatment is carried o...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the wood described in step one is poplar, larch, sylvestris pine, ash, rubber wood or bamboo. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the purity of the oxygen in step 2 is greater than 99.99%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com