Three-color plate

A color plate and plate layer technology, applied in the field of three-color plate, can solve the problems of inability to meet the requirements of three colors, high production cost, unfriendly screen printing, etc., and achieve rich colors, fast production, good water resistance and sun protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

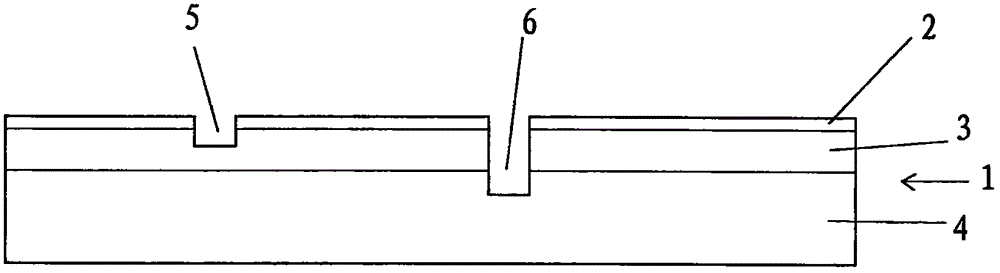

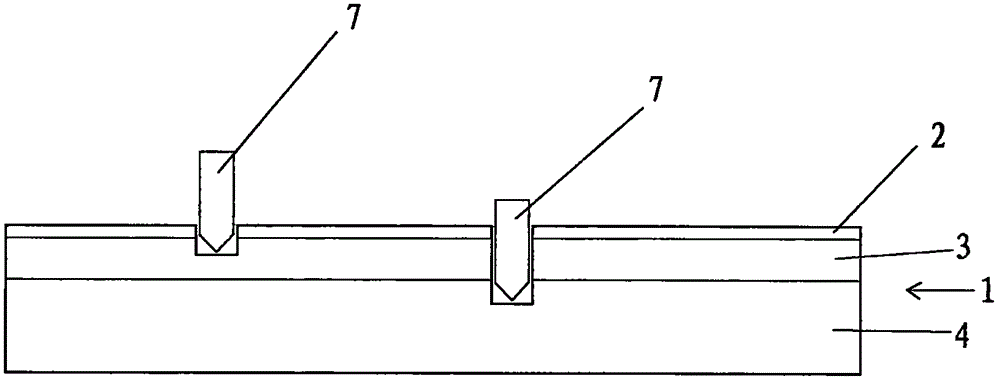

[0014] refer to Figure 1-2 As shown, a three-color board includes an ABS substrate layer 1 and a surface printing layer 2. The ABS base layer is formed by extruding and compounding a first ABS board layer 3 and a second ABS board layer 4. The first ABS board layer The board layer is located on the top of the second ABS board layer, and the surface printing layer is a color layer printed on the upper surface of the first ABS board layer by transfer printing. The first ABS board layer, the second ABS board layer and the surface The printing layer adopts different colors, and the thickness of the second ABS board layer is greater than the thickness of the first ABS board layer; the characters and / or patterns of different depths are engraved on the surface printing layer, and some of the characters and / or patterns are 5 Engraved into the first ABS plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com