Double pneumatic punch needle device

A double-pneumatic, stamping needle technology, applied in printing, typewriters, manufacturing tools, etc., can solve problems such as unsatisfactory use requirements, many marking contents, and slow speed, so as to avoid mutual wear, enhance accuracy, and reduce mechanical contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to allow the purpose, features and functions of the present invention to be further understood, the present invention will be further described in conjunction with specific embodiments and accompanying drawings:

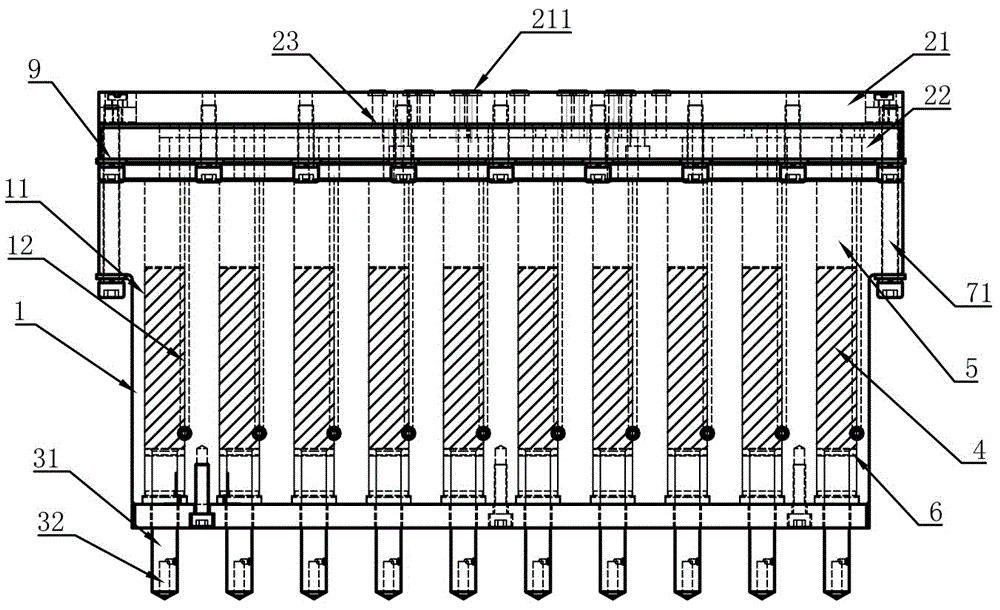

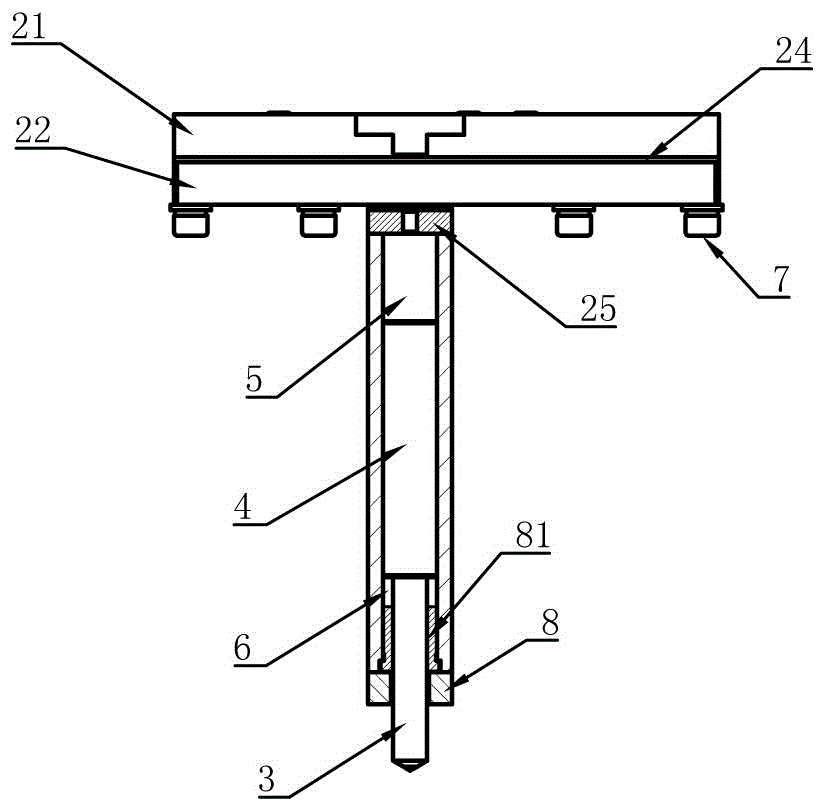

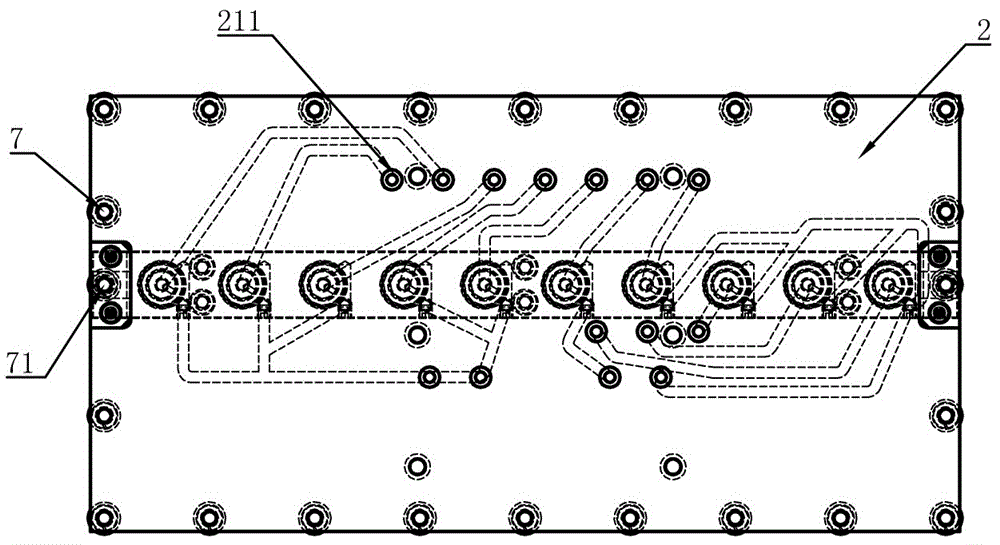

[0022] Such as Figure 1-4 , a double pneumatic punching needle device, comprising: a punching needle base, an air circuit board and a punching needle part, the punching needle base is installed at the bottom of the air circuit board, a piston rod is arranged inside the punching needle base, and the bottom of the piston rod is installed Punching parts, the top of the piston rod and the air circuit board form the upper air chamber, the bottom of the piston rod and the punch seat form the lower air chamber, the air circuit of the air circuit board is connected with the upper air chamber and the lower air chamber separately, controlled by double air pumps The air volume inside the upper air cavity and the lower air cavity is quickly inflated to press dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com