Memory type mirror surface drive of automobile rearview mirror

An automobile rear-view mirror and driver technology, which is applied in the field of automobile rear-view mirrors, can solve the problems of large directional torque, loss of memory function, uneven torque, etc., and achieves the effects of reasonable layout, compact structure and uniform torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

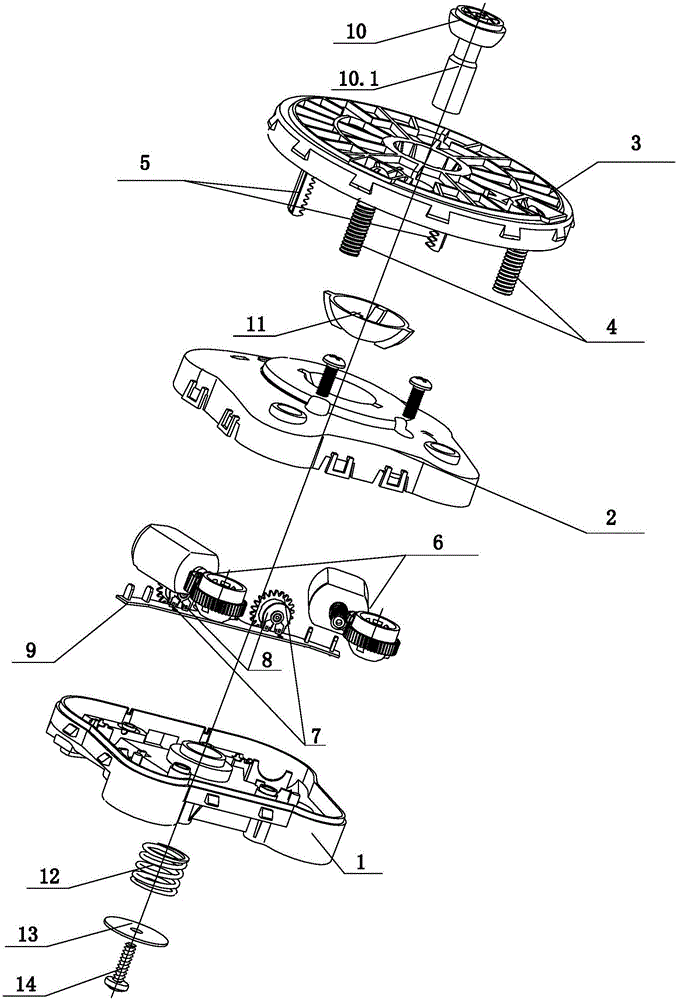

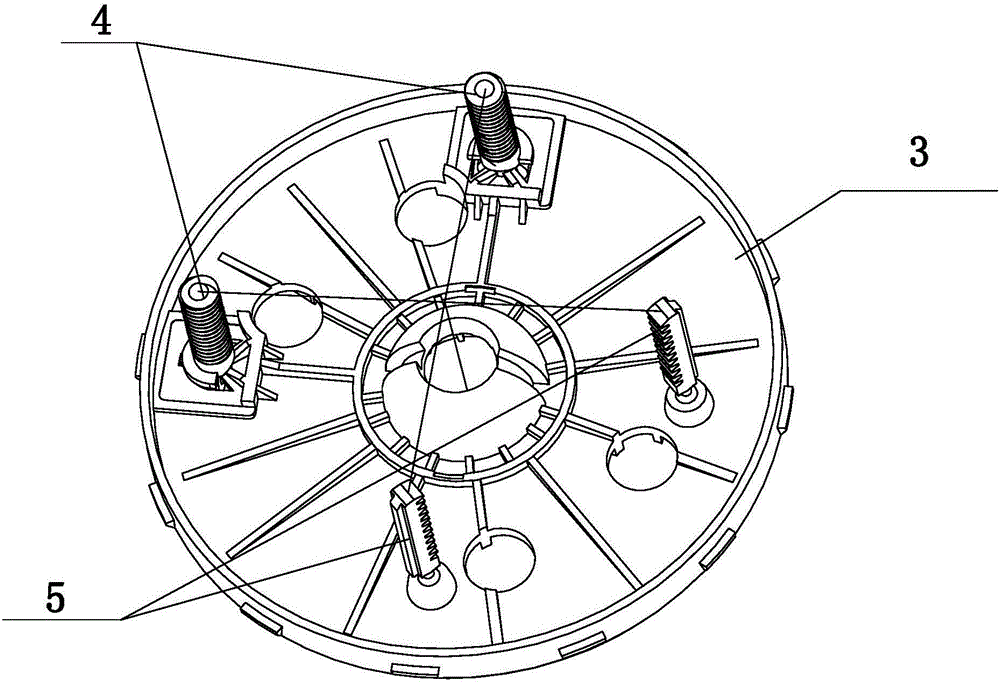

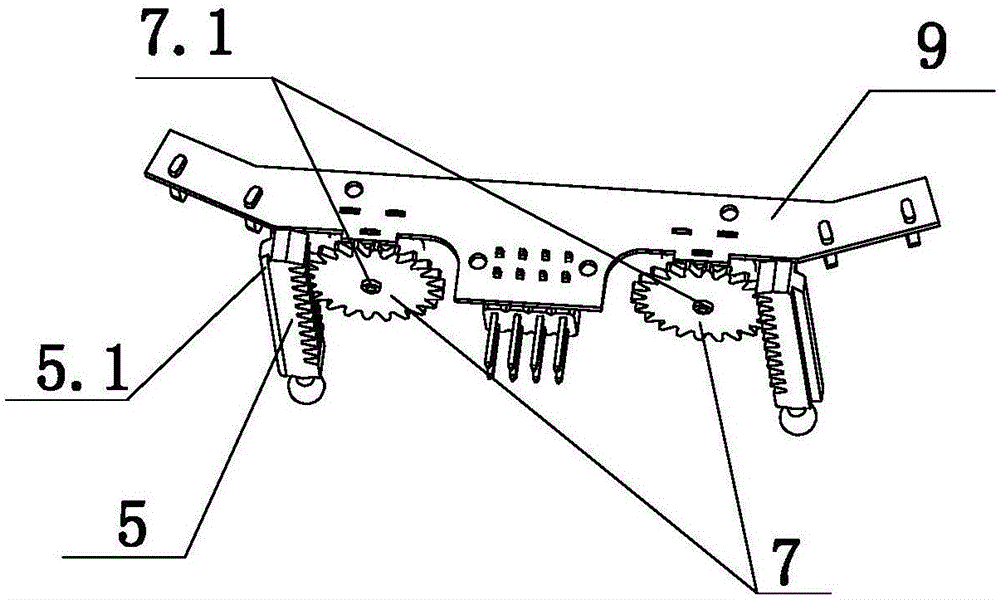

[0026] like Figure 1-8 As shown in the figure, a memory type automobile rearview mirror mirror driver includes an upper cover 2, a base 1 and a mirror floating plate 3 that can be adjusted relative to the base 1 within a certain angle range, and is vertically installed on the base 1 and the mirror floating plate 3. The lifting worm 4 used for transmission and the driving device 6 used for driving the movement of the lifting worm 4 when the two mirror surfaces are symmetrically arranged between them, the upper ends of each of the two lifting worms 4 are hinged with the mirror floating plate 3, and the two The axis A and axis B where 4 are located are arranged at 90 degrees on one side of the driver; the other side of the driver is provided with a memory device that enables the driver to have a memory function. A and the axis B are composed of two sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com