A mobile motor car material sequence installation error prevention monitoring device

A technology for sequential installation and monitoring of devices, applied in motor vehicles, transportation and packaging, etc., to ensure assembly quality, prevent assembly errors, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

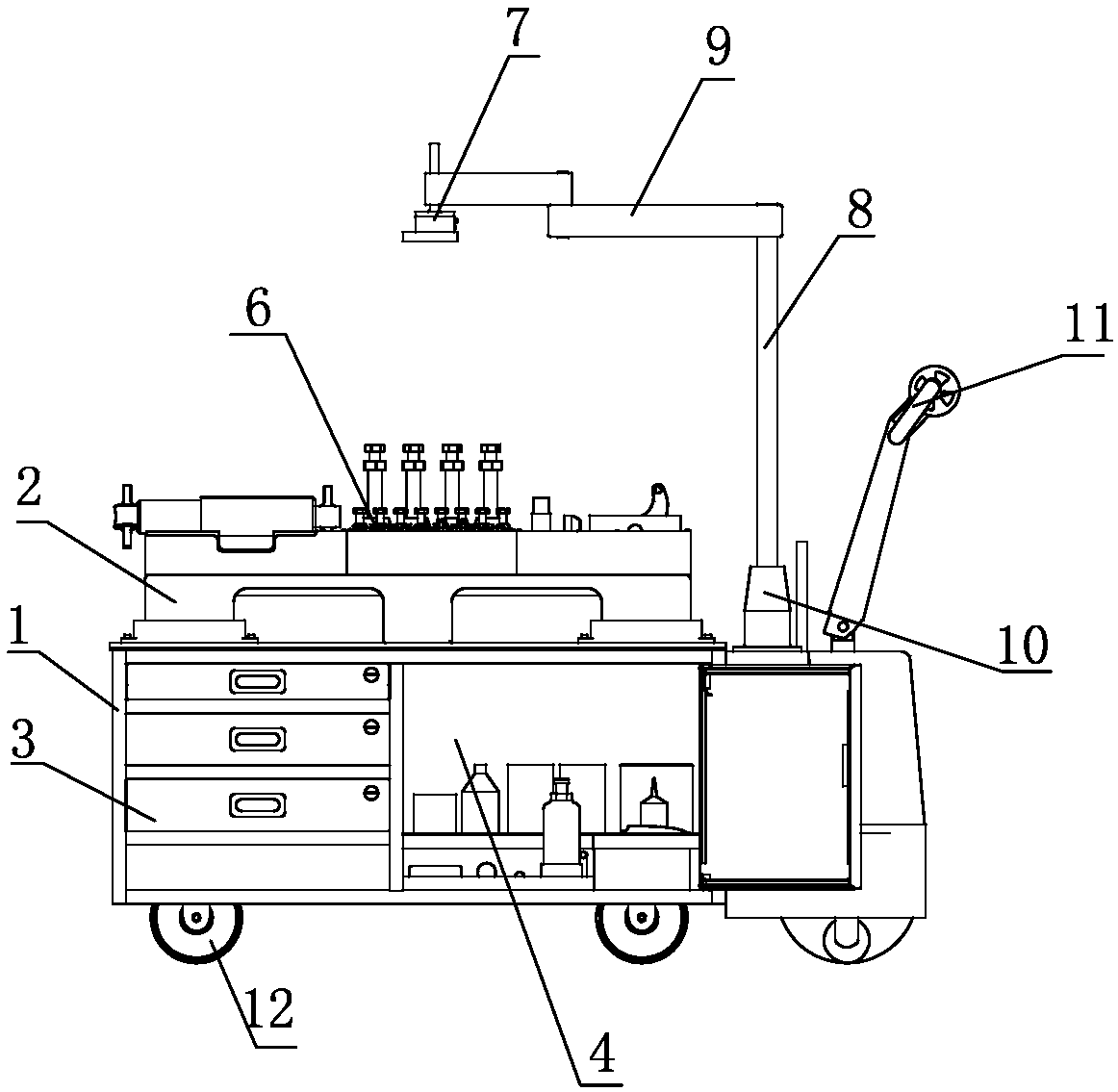

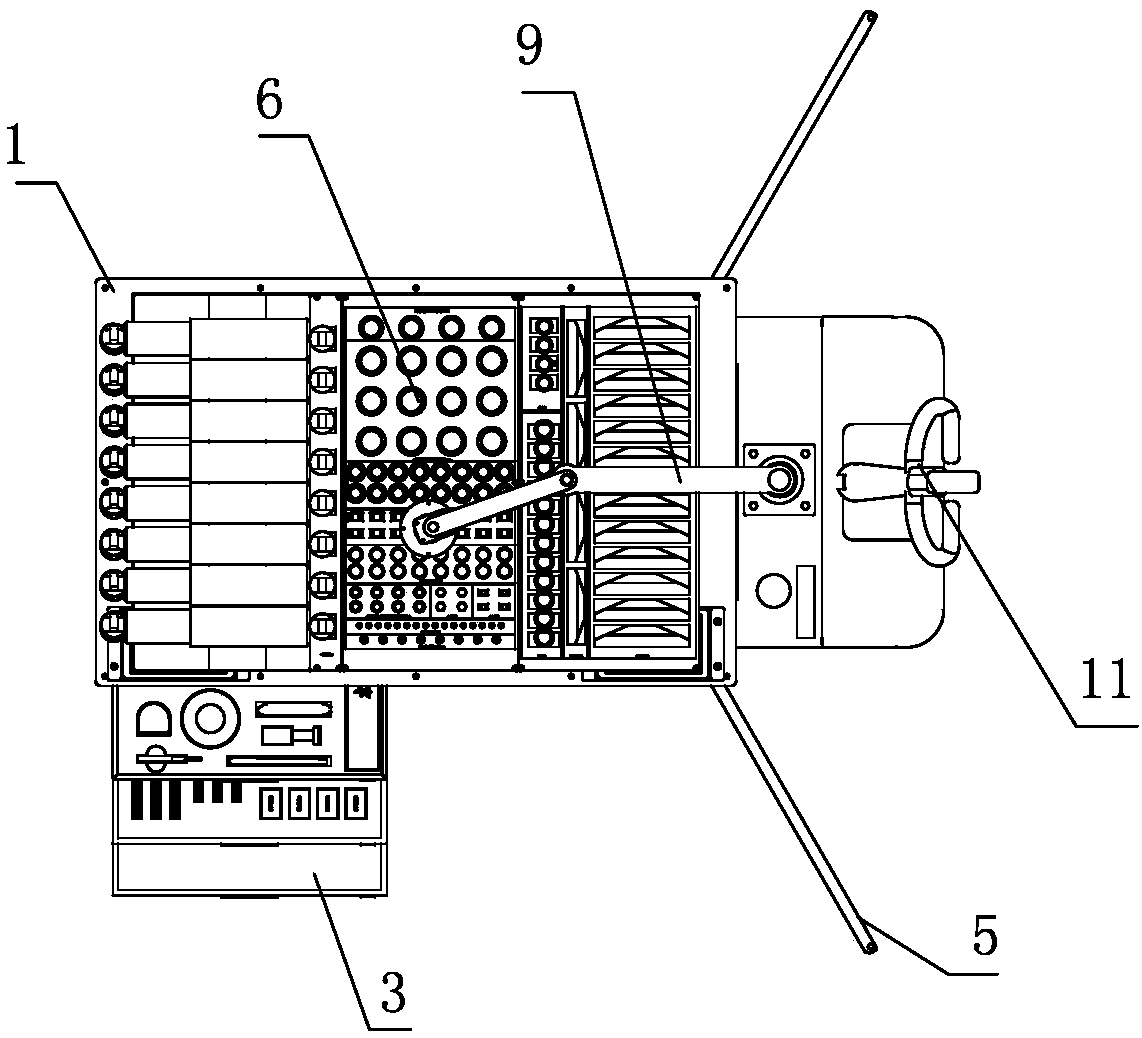

[0024] Such as figure 1 and figure 2 As shown in the figure, a mobile motor car material sequence installation error prevention monitoring device includes a loading system, a traction system, an identification system and a control system.

[0025] The loading system includes a vehicle body 1 and a material tray 2 , and the material tray 2 is detachably installed on the upper end of the vehicle body 1 . The car body 1 includes an auxiliary tool drawer 3 and an auxiliary material box 4, the auxiliary tool drawer 3 is used to place auxiliary tools such as calipers, etc. required for the material assembly process of the motor car, and the auxiliary material box 4 is used to place tapes, wooden hammers, Accessory tools such as jacks; the auxiliary tool drawer 3 includes a plurality of auxiliary tool drawers 3 evenly installed on the left side of the car body 1; the auxiliary material box 4 is located at the right part of the car body 1, and the auxiliary tool The front and back ...

Embodiment 2

[0035] The identification system includes a trigger light source and a wavelength detection camera. The trigger light source includes multiple types of light sources that can emit different wavelengths; the bottom of the material tank is provided with a light source placement groove; the trigger light that emits different wavelengths The light sources are respectively installed in the light source placement grooves in different material areas; the wavelength detection camera is installed above the material tray through the identification mounting bracket, and the wavelength detection camera is used to identify the trigger light source in different material areas. The signal output end of the wavelength detection camera is electrically connected with the signal input end of the controller.

[0036] The traction system includes a traction motor, a transmission mechanism and a control panel. The traction motor is installed at the lower part of the front end of the vehicle body. T...

Embodiment 3

[0039] The identification system includes an address recognition card and an address recognizer. The address recognition card records information of different material areas, and the address recognizer is used to read the information on the address recognition card.

[0040] The bottom of the material tank is provided with an address identification slot; the address cards that record different addresses are respectively installed in the address identification slots in different material areas; the address recognizer passes through the The identification mounting frame is installed above the material pallet. The signal output terminal of the address recognizer is electrically connected with the signal input terminal of the controller.

[0041] The working principle of this embodiment is that the address recognition card is blocked by the material in the initial state; when the material is taken, the address recognition card is recognized by the address recognizer; Take the seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com