Inclined tube oil separation system for treating low-temperature harbor district oily sewage

A technology for oily sewage and inclined pipes is applied in the field of sewage treatment, which can solve the problems of increasing sewage treatment volume, restricting the transformation process, and limited use of sewage treatment centers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

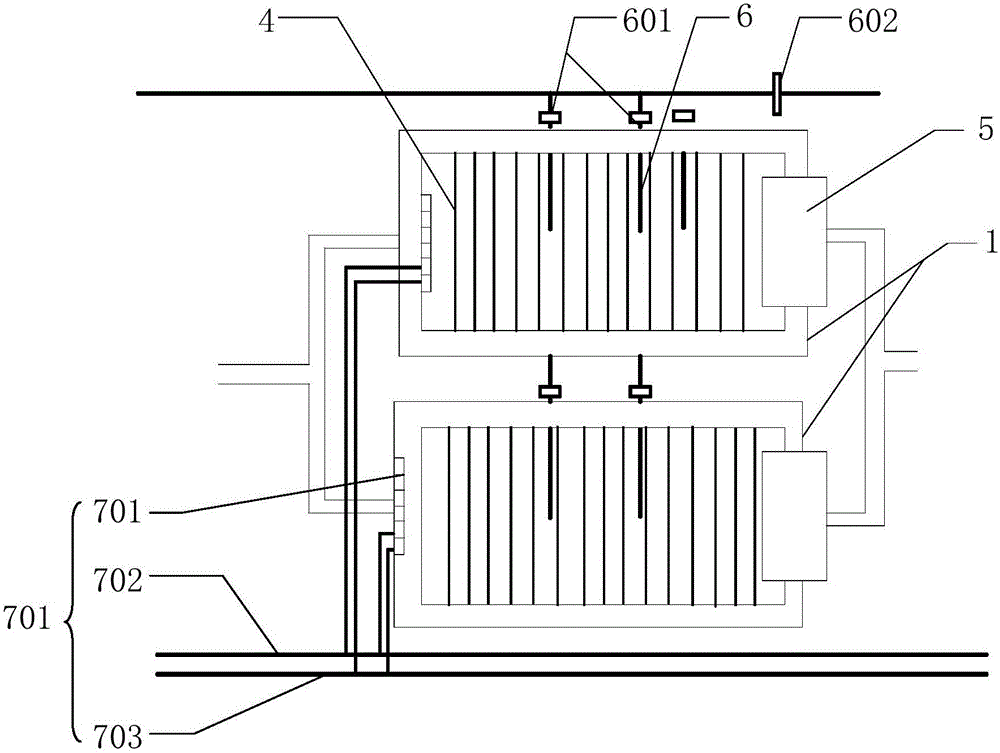

[0033] In view of the large increase in the amount of oily sewage treatment in the port area, the structure of the inclined pipe oil separation system of the oily sewage treatment device in the Nanjiang port area of Tianjin Port was optimized and improved; the inclined pipe oil separation system consisted of two parallel inclined pipes Grease trap and steam tracing system 7; of which:

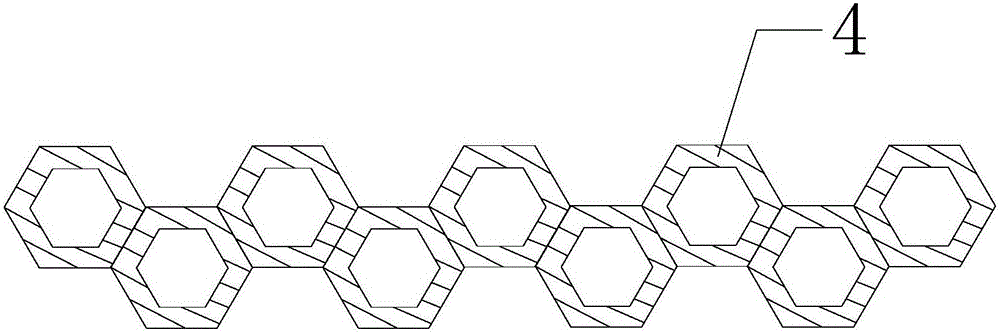

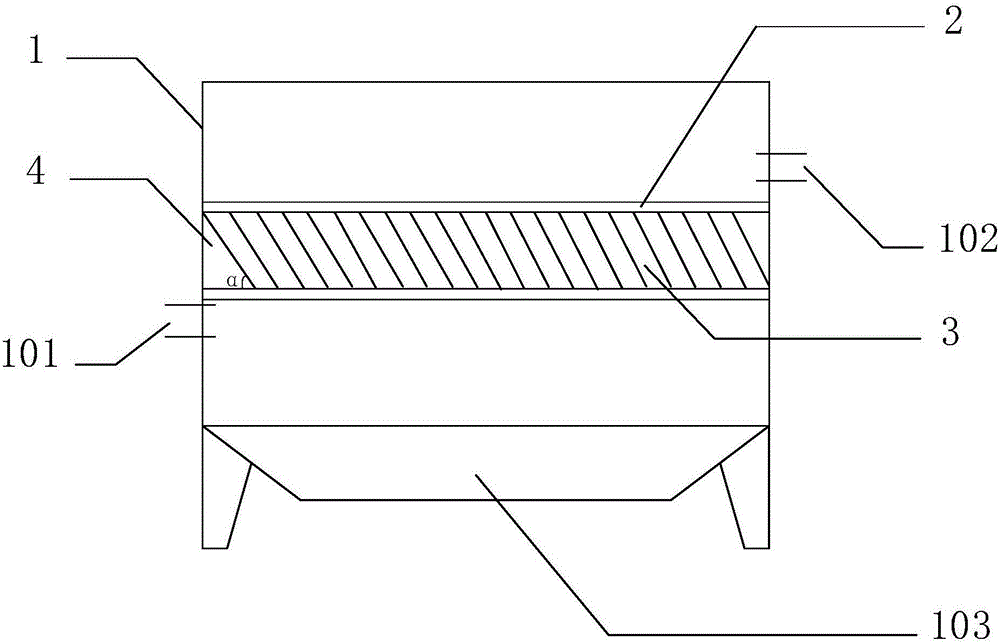

[0034] Each set of inclined tube grease traps includes a closed tank body 1 with a length x width x height of 10.5m x 4.0m x 4.5m; the inner chamber of the tank body 1 is horizontally arranged from top to bottom and fixed in the tank body inclined tube grease trap 1. The inclined tube crimping tube 2 and the inclined tube supporting tube 3 on the inner wall divide the inner cavity of the tank body 1 from top to bottom into an oil slick area, a water-oil separation area and a deposition area with a volume ratio of 5:4:5; Wherein, the pipe diameters of the liquid inlet 101 and the liquid outlet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap