A hydrogen power energy system

A technology of electric energy and hydrogen energy, which is applied in the field of energy systems and hydrogen energy systems, can solve the problems of being unable to promote, consuming other resources, and being expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

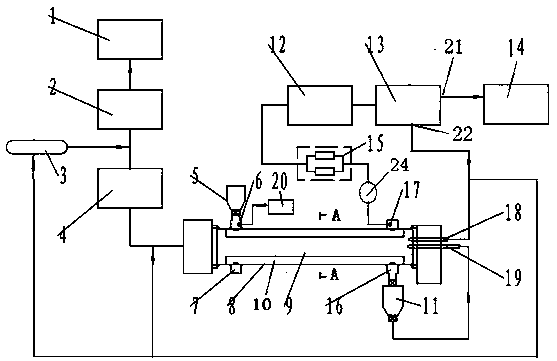

Embodiment 1

[0022] The hydrogen power energy system of the present invention is as figure 1As shown, it includes coal powder silo 5, partition wall rotary kiln 8, waste heat power generation unit 4 with desulfurization equipment, high-pressure low calorific value fuel preparation unit 1, gas booster device 2, reducing gas storage tank 3, and steam generator 20 , a desulfurization device 15, a gas component analyzer 24, a water spray dust collector 12, a hydrogen extraction device 13 and a hydrogen energy preparation unit 14. The partition wall rotary kiln includes a kiln body, a kiln head cover, a kiln tail cover, a coke powder hopper 11, a feeding ring 7 and a discharge ring 16. The kiln body is composed of a kiln chamber 9 and an annular material passage 10. Ring material channel connection. The kiln hood is provided with a gas fuel burner 18 and a solid fuel burner 19 . The pulverized coal silo is connected to the feed ring, and the discharge ring is connected to the solid fuel burne...

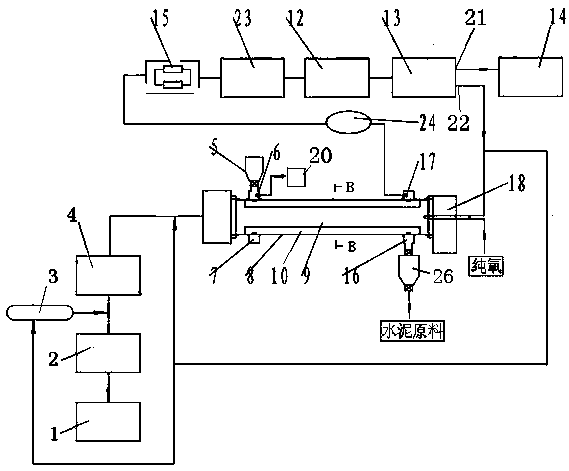

Embodiment 2

[0025] Another embodiment of the present invention is as figure 2 As shown, it includes coal powder silo 5, partition wall rotary kiln 8, waste heat power generation unit 4 with desulfurization equipment, high-pressure low calorific value fuel preparation unit 1, gas booster device 2, reducing gas storage tank 3, and steam generator 20 , desulfurization device 15, water spray dust collector 12, denitrification device 23, gas composition analyzer 24, hydrogen extraction device 13 and hydrogen energy preparation unit 14. The partition wall rotary kiln includes a kiln body, a kiln head cover, a kiln tail cover, a gasification residue bin 26, a feeding ring 7 and a discharge ring 16. The kiln body is composed of a kiln chamber 9 and a straight material channel 30. Connect with straight material channel. The kiln tail cover is provided with a gas fuel burner 18 . The pulverized coal silo is connected to the feed ring, and the discharge ring is connected to the cement raw materia...

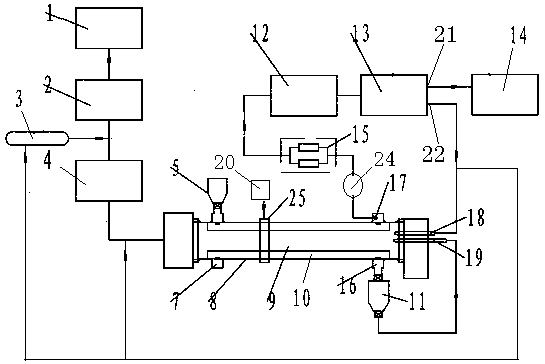

Embodiment 3

[0028] The third embodiment of the present invention is as image 3 As shown, it includes coal powder silo 5, partition wall rotary kiln 8, waste heat power generation unit 4 with desulfurization equipment, high-pressure low calorific value fuel preparation unit 1, gas booster device 2, reducing gas storage tank 3, and steam generator 20 , a gas component analyzer 24, a desulfurization device 15, a water spray dust collector 12, a hydrogen extraction device 13 and a hydrogen energy preparation unit 14. The partition wall rotary kiln includes a kiln body, a kiln head cover, a kiln tail cover, a coke powder hopper 11, a feeding ring 7 and a discharge ring 16. The kiln body is composed of a kiln chamber 9 and an annular material passage 10. Ring material channel connection. The kiln hood is provided with a gas fuel burner 18 and a solid fuel burner 19 . The pulverized coal silo is connected to the feed ring, and the discharge ring is connected to the solid fuel burner through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com