A method for preparing cement kiln fuel by using aluminum electrolysis waste cathode

A technology of aluminum electrolysis and cement kiln, which is applied in the field of cement, can solve the problems of insufficient reaction, reduction of cement strength, and the addition of no more than 5%, so as to alleviate the effect of increasing depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

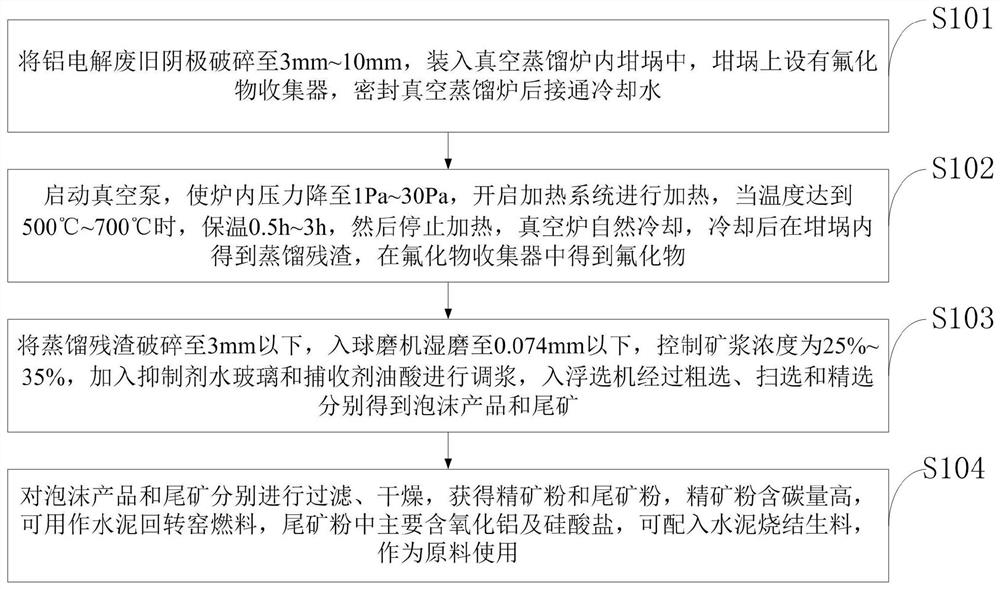

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 100kg of waste and old cathodes, after testing, the carbon content is 64.1wt%, the NaF content is 6.45wt%, and the NaF content is 6.45wt%. 3 AlF 6 The content is 2.01wt%, containing CaF 2 The content is 2.17wt%, Al 2 o 3 Content is 10.25wt%, SiO 2 The content is 2.24wt%, and the sodium content is 4.71wt%. It is crushed to 3-10mm, put into the crucible in the vacuum distillation furnace, and the crucible is provided with a fluoride collector, and the cooling water is connected after sealing the vacuum distillation furnace.

[0036] (2) Start the vacuum pump, make the pressure in the furnace drop to 10Pa, turn on the heating system to heat, when the temperature reaches 600 ° C, keep warm for 2 hours, then stop heating, the vacuum furnace is naturally cooled, and after cooling, 91.5 kg of distillation residue is obtained in the crucible, Obtain fluoride 8.5kg in the fluoride collector, and its main components are sodium fluoride and cryolite.

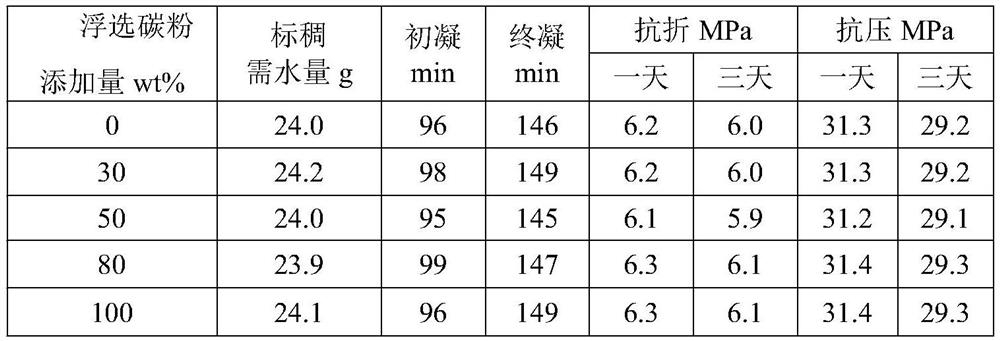

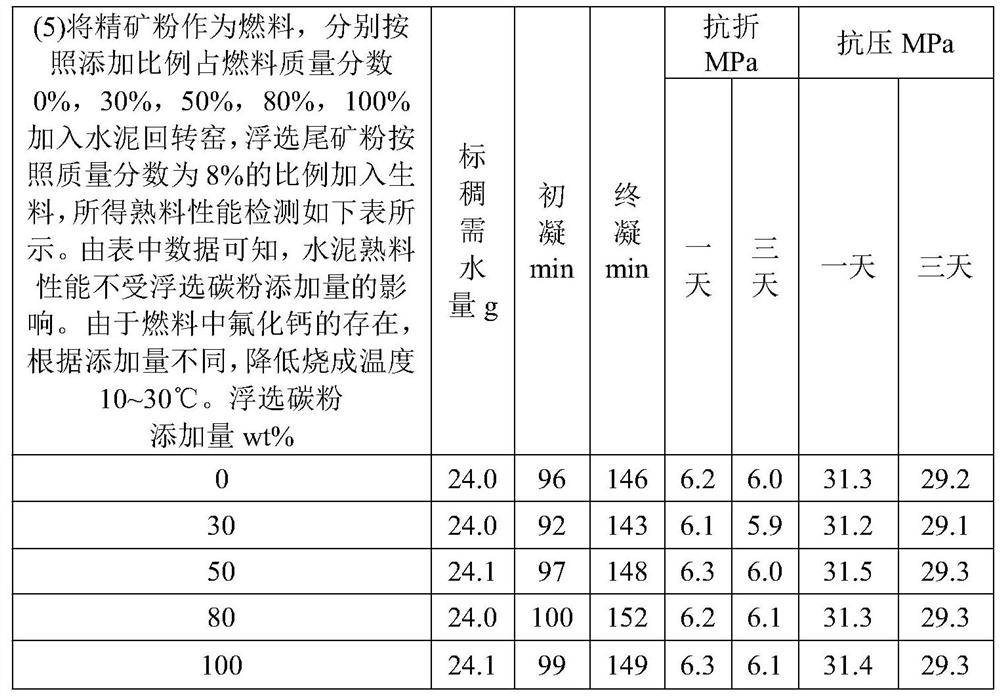

[0037] (3) Cru...

Embodiment 2

[0042] (1) Take 100kg of waste and old cathodes, after testing, the carbon content is 49.5wt%, the NaF content is 7.22wt%, and the NaF content is 7.22wt%. 3 AlF 6 The content is 2.52wt%, containing CaF 2 The content is 2.5wt%, Al 2 o 3 Content is 11.79wt%, SiO 2 The sodium content is 2.58wt%, and the sodium content is 5.42wt%. It is crushed to 3-10mm and put into a crucible in a vacuum distillation furnace.

[0043] (2) Start the vacuum pump to reduce the pressure in the furnace to 5 Pa, turn on the heating system for heating, and when the temperature reaches 550° C., keep warm for 2 hours, then stop heating, and the vacuum furnace cools naturally. After cooling, 91.1 kg of distillation residue is obtained in the crucible, Obtain 9.9kg of fluoride in the fluoride collector, the main components of which are sodium fluoride and cryolite.

[0044] (3) Crush the distillation residue to less than 3mm, put it into a ball mill for wet grinding to less than 0.074mm, control the p...

Embodiment 3

[0048] (1) Take 100kg of waste and old cathodes, after testing, the carbon content is 37.5wt%, the NaF content is 11.25wt%, and the NaF content is 11.25wt%. 3 AlF 6 The content is 3.41wt%, containing CaF 2 The content is 3.78wt%, Al 2 o 3 Content is 17.84wt%, SiO 2 The content is 3.9wt%, and the sodium content is 8.2wt%. It is crushed to 3-10mm, and put into a crucible in a vacuum distillation furnace. A fluoride collector is arranged on the crucible, and the cooling water is connected after sealing the vacuum distillation furnace.

[0049] (2) Start the vacuum pump, make the pressure in the furnace drop to 10Pa, turn on the heating system for heating, when the temperature reaches 700°C, keep warm for 1h, then stop heating, the vacuum furnace cools naturally, and after cooling, 85.2kg of distillation residue is obtained in the crucible, Obtain fluoride 14.8kg in the fluoride collector, and its main component is sodium fluoride and cryolite.

[0050] (3) Crush the distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com