Soaking device for microbial wine making

A technology of microorganisms and feeding devices, applied in the field of microbial wine brewing, can solve problems such as complex process, failure to reach the final goal, and influence of soaking degree, and achieve the effects of improving full absorption of water, reducing production costs, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with examples, which are only used to explain the invention, and are not intended to limit the scope of the present invention.

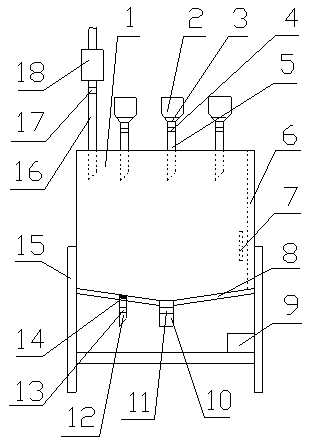

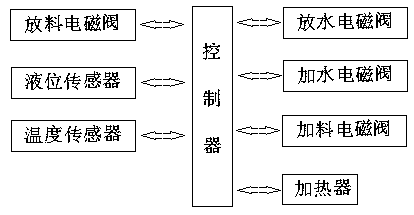

[0011] A soaking device for microbial brewing, comprising a barrel body 1, a feeding device 3, a liquid level sensor 6, a temperature sensor 7, a heater 8, a controller 9, a discharge pipe 10, a discharge solenoid valve 11, a water discharge pipe 12, Drain solenoid valve 13, mesh pad 14, shelf 15, water adding pipe 16, water adding solenoid valve 17 and water purifier 18, staving 1 is arranged on the shelf 15, and feeding device 3 is arranged on staving 1 just above by installing and comprises measuring cylinder 2. The feeding solenoid valve 4 and the feeding pipe 5. One end of the feeding pipe 5 faces the barrel body 1 and the other end is connected to the measuring cylinder 2. The feeding solenoid valve 4 is arranged on the feeding pipe 5, and the liquid level sensor 6 is vertically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com