A rotating pecvd system

A technology of rotating gears and control systems, applied in the field of PECVD, can solve the difficulties of graphene metal matrix composites, the difficulty of solving the problems of uniformity of dispersion, uniform formation of graphene, etc., to achieve favorable quality and heat transfer, and improve coating The effect of uniformity and uniform coating coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

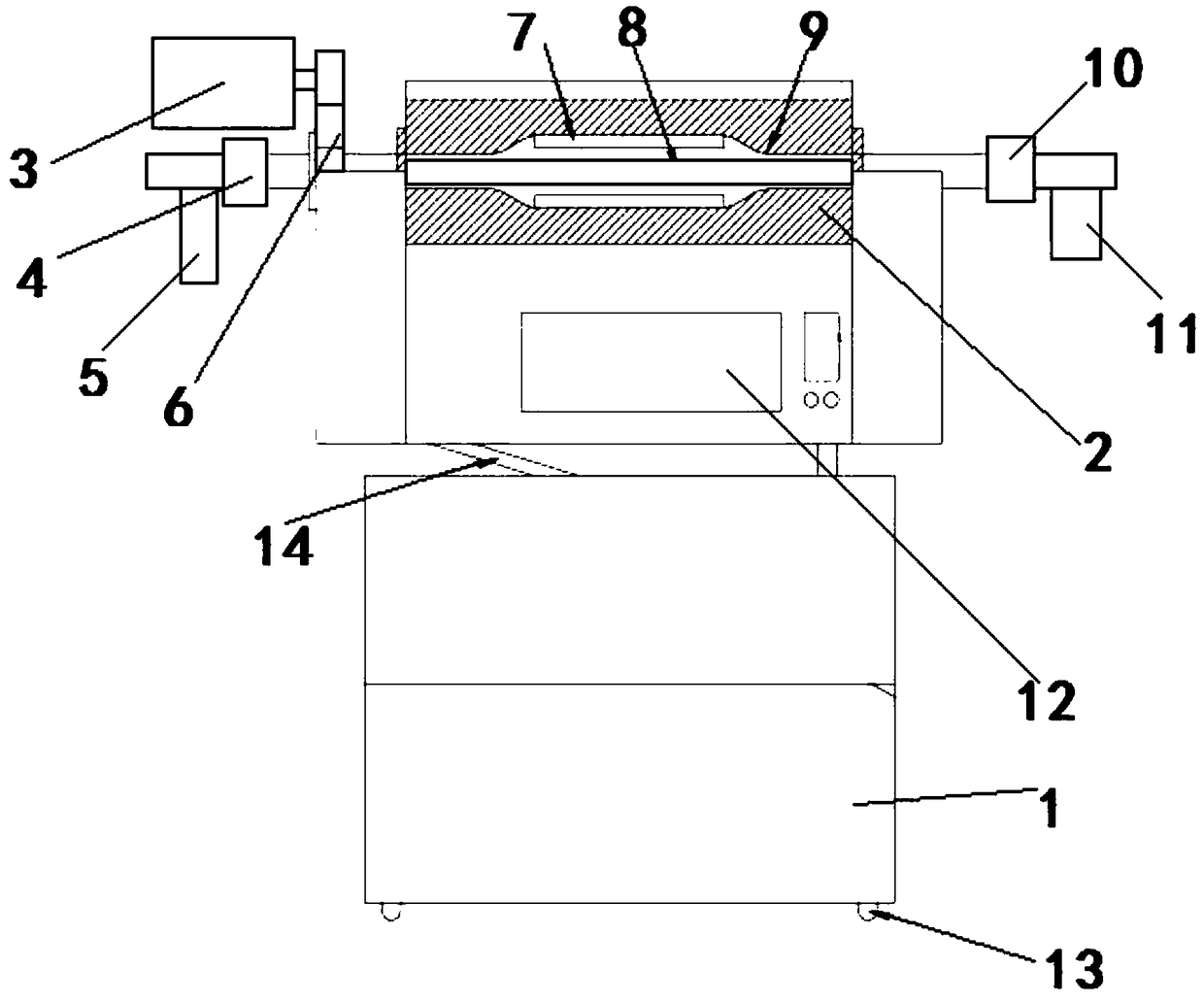

[0020] Such as figure 1 A rotary PECVD system shown includes a mounting table 1, a tube furnace 2 is installed on the mounting table 1, and the tube furnace 2 and the mounting table 1 are connected to each other through a hydraulic telescopic rod 14, and the tube furnace 2 is connected to the mounting table 1. The maximum inclination angle between the stations 1 is 15 degrees to ensure that the reaction precursors are mixed more fully in the quartz tubes with thin ends and thick middle. A quartz tube 9 is installed in the middle of the tube furnace 2, and the quartz tube 9 is thin at both ends and thick in the middle to improve the reaction effect. Mutual interference, the middle of the quartz tube 9 is provided with a screw feeder 8, the feed end of the quartz tube 9 is provided with a gas supply system 5 and a feed hopper 4 in tur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap