Washing barrel and washing machine

A technology for washing tubs and washing machines, which is applied to other washing machines, washing devices, textiles and papermaking, etc. It can solve the problems of not being able to fit the structure of the integrated tub well, the installation process of the sheet metal reinforcement is cumbersome, and the internal space cannot be fully utilized. , to achieve the effect of improving user experience, improving washing effect and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

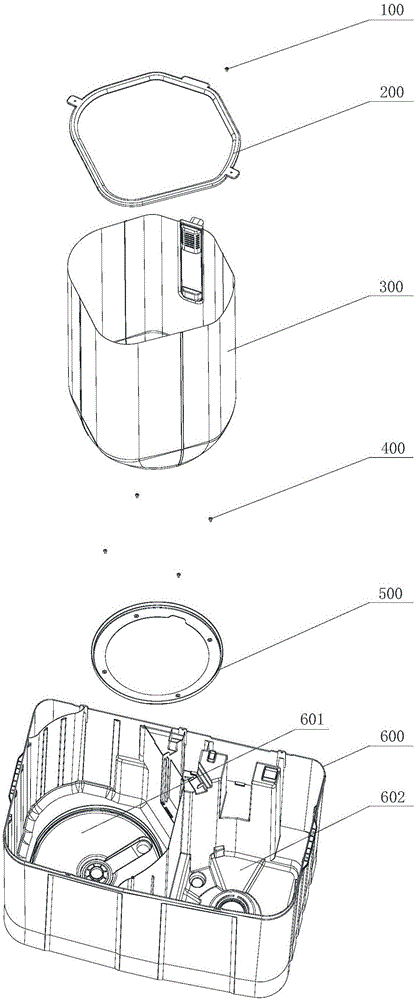

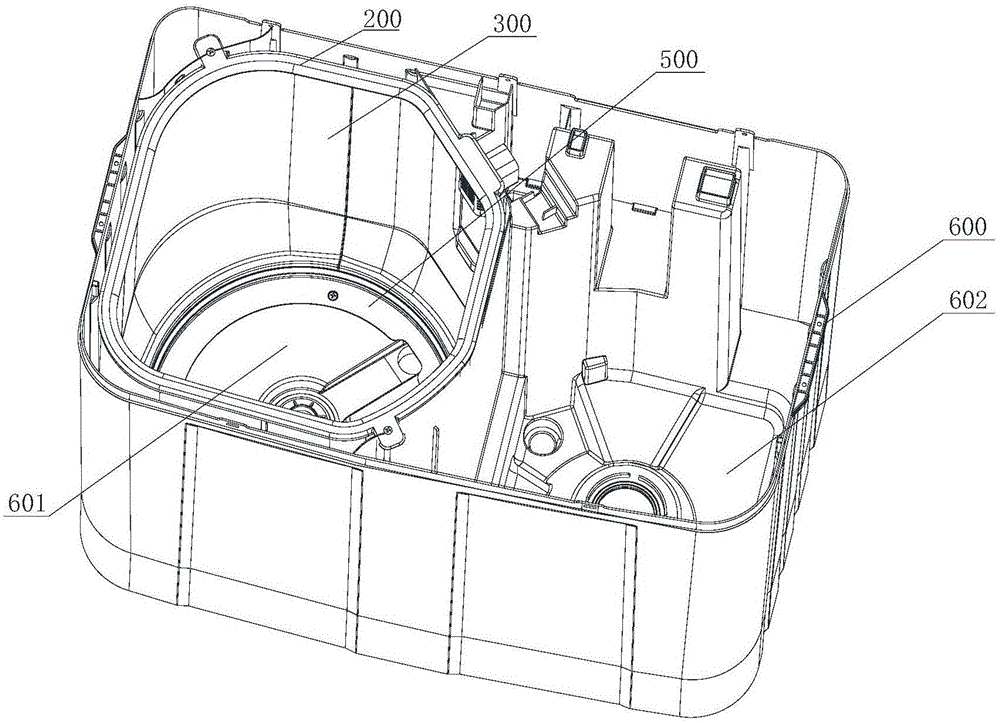

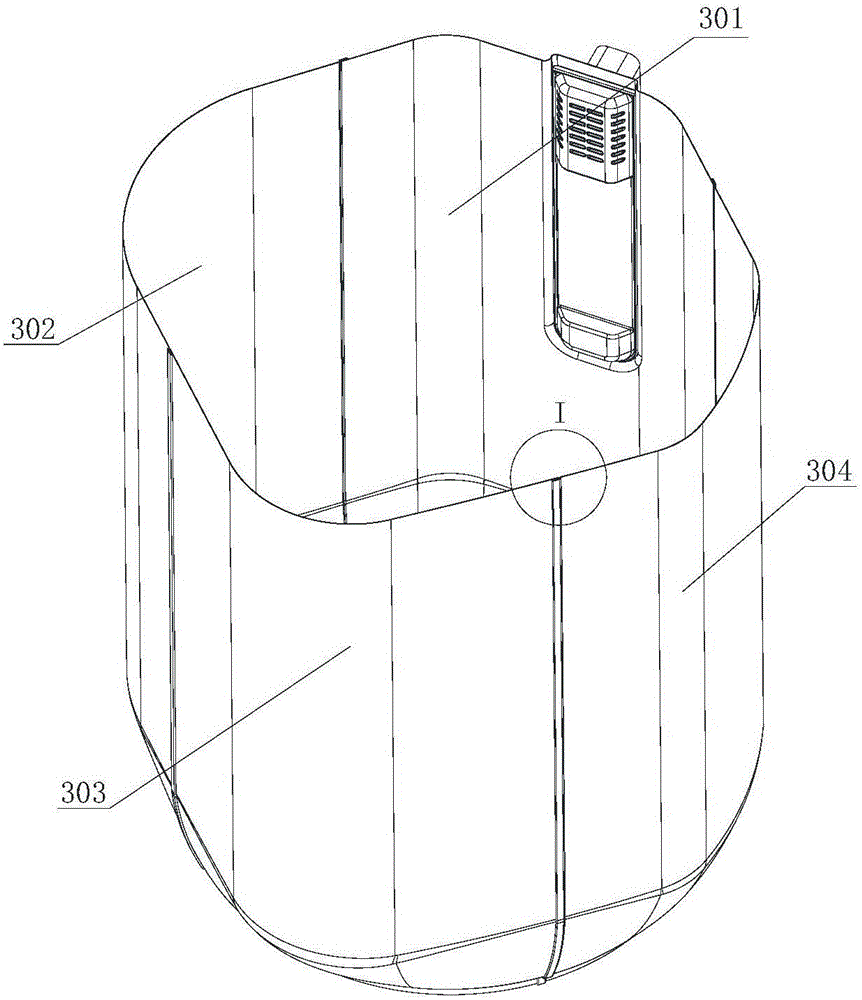

[0036] A kind of washing bucket and washing machine of the present invention are described in detail below in conjunction with accompanying drawing:

[0037] A washing bucket has a bucket body for holding laundry, the bucket body is a cylindrical structure formed by assembling a plurality of bucket body assembly pieces to form a peripheral wall seal, the two ends of the cylindrical structure are open, and the peripheral wall is sealed; the bucket Fixed connection between body assembly pieces.

[0038] The cylindrical structure of the present invention is not limited to a cylindrical structure. Since the washing tub is formed by assembling multiple bucket body assembly pieces, the washing bucket can be designed into a desired shape, and only the shape and structure design of each bucket body assembly piece is required. , and then make a fixed connection.

[0039] The washing bucket of the present invention can maximize the use of the inner space of the washing machine and incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com