Printing and flocking process capable of improving elasticity of specific portions of cloth

A technology for specific parts and fabrics, which is applied to devices for coating liquids on surfaces, textiles and papermaking, pretreatment surfaces, etc. The effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] see figure 1 - image 3, Figure 5 , a printing and flocking process for increasing the elasticity of specific parts of the fabric, comprising the following steps in sequence:

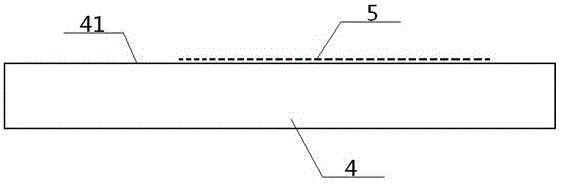

[0055] Pretreatment step: firstly clean the upper surface 41 of the platen 4, and then evenly spray the release agent 5 on the cleaned upper surface 41;

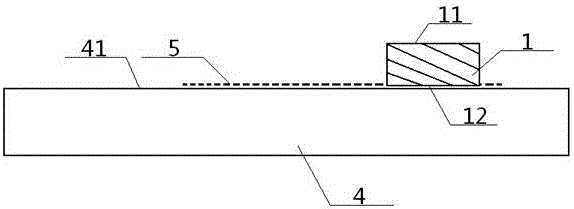

[0056] One glue step: print No. 1 glue 1 on the upper surface 41 after spraying the release agent 5, and the No. 1 bottom surface 12 of the No. 1 glue 1 contacts the upper surface 41 through the release agent 5;

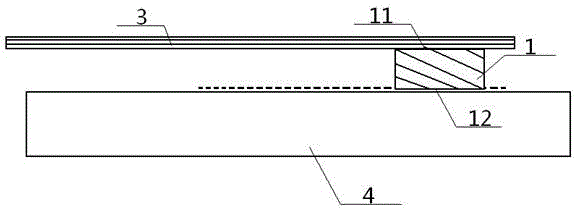

[0057] Fabric laying steps: Lay fabric 3 on the top of No. 1 glue 1 to obtain No. 1 product. The bottom surface of fabric 3 is bonded to No. 1 top surface 11 of No. 1 glue 1. The junction of cloth 3 and No. 1 glue 1 is For the part to be increased elasticity;

[0058] Electrostatic flocking step: first turn the No. 1 product up and down so that the No. 1 glue 1 and fabric 3 are arranged up and down in sequence, and then electrost...

Embodiment 2

[0061] see figure 1 - Figure 4 , Figure 6 , a printing and flocking process for increasing the elasticity of specific parts of the fabric, comprising the following steps in sequence:

[0062] Pretreatment step: firstly clean the upper surface 41 of the platen 4, and then evenly spray the release agent 5 on the cleaned upper surface 41;

[0063] One glue step: print No. 1 glue 1 on the upper surface 41 after spraying the release agent 5, and the No. 1 bottom surface 12 of the No. 1 glue 1 contacts the upper surface 41 through the release agent 5;

[0064] Fabric laying steps: Lay fabric 3 on the top of No. 1 glue 1 to obtain No. 1 product. The bottom surface of fabric 3 is bonded to No. 1 top surface 11 of No. 1 glue 1. The junction of cloth 3 and No. 1 glue 1 is For the part to be increased elasticity;

[0065] The second glue step: first print No. 2 glue 2 on the top surface of the fabric 3 in the No. 1 product to obtain the No. 2 product. The positions of the No. 2 glu...

Embodiment 3

[0069] Basic content is the same as embodiment 1 or embodiment 2, and difference is:

[0070] The printing process of No. 1 glue 1 and No. 2 glue 2 is screen printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com