A waste heat power generation system

A waste heat power generation and generator technology, which is applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of power generation efficiency attenuation, large steam fluctuation range, and large amount of smoke and dust from hazardous waste incineration, and achieve high steam utilization rate, Improved power generation efficiency and stable power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

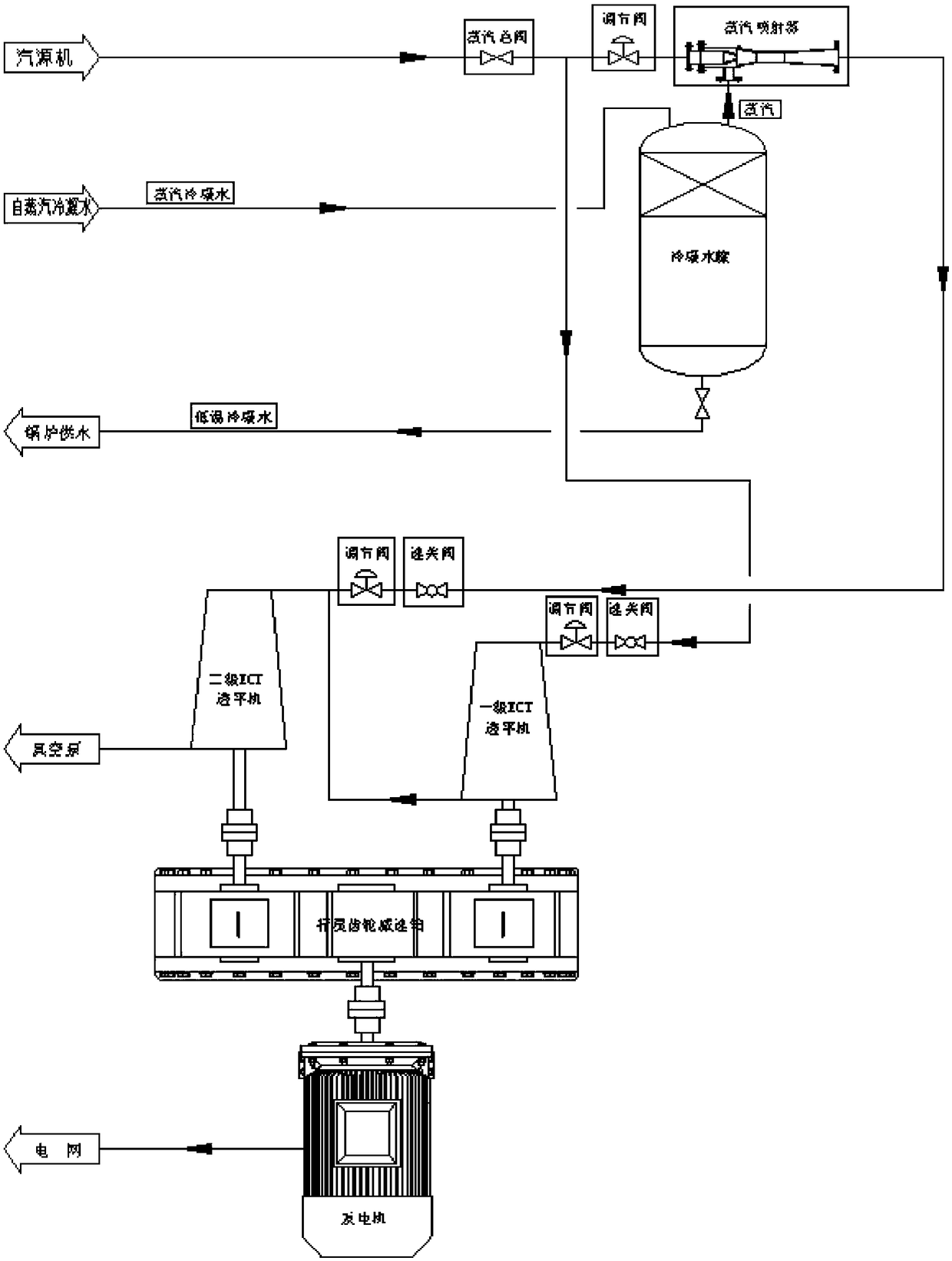

[0012] As shown in the figure, a waste heat power generation system includes a steam source machine, a steam channel, a turbine, and a generator. The steam source machine collects waste heat and converts it into steam, which is transported to the turbine through the steam channel to be converted into mechanical kinetic energy, and the mechanical kinetic energy is transferred. The steam channel is equipped with a regulating valve and a quick-closing valve, which can adjust the on-off of steam in each section of the steam channel. The turbine is divided into a first-stage turbine, a second-stage turbine, and a first-stage turbine. The flat machine and the second-stage turbine are connected in series on the steam channel of the steam source machine, and a Venturi ejector is installed on the steam channel next to the steam inlet of the second-stage turbine, and the Venturi ejector is connected with the first-stage turbine. machines in parallel.

[0013] The Venturi injector is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com