Washing machine and motor fan impeller

A wind impeller and blade technology, applied in the field of washing machines, can solve problems such as not being able to meet the heat dissipation requirements of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

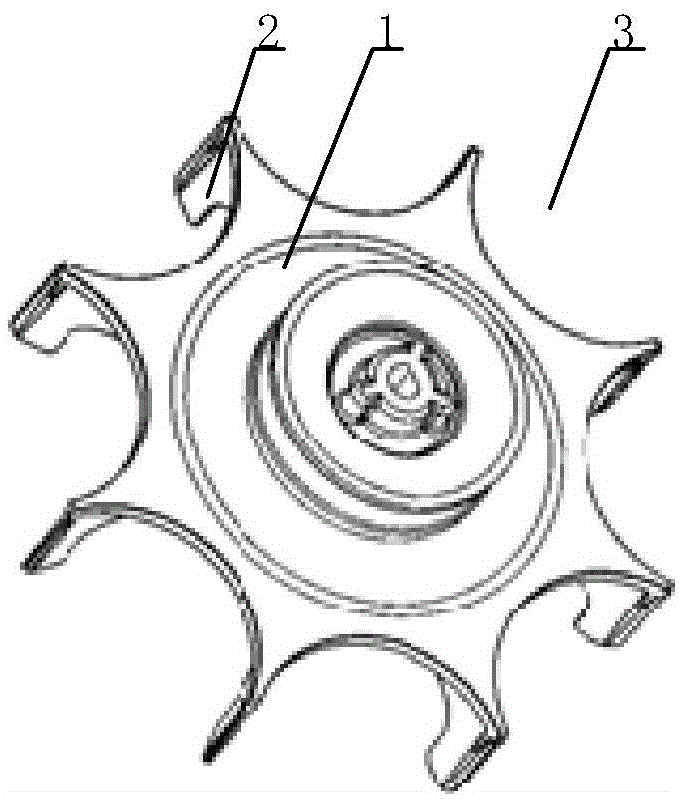

[0026] Therefore, the first core of the present invention is to disclose a motor wind impeller to achieve the purpose of improving the heat dissipation efficiency of the motor; the second core of the present invention is to disclose a washing machine. Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

[0027] see Figure 2 to Figure 5 As shown, the motor wind impeller includes a circular thin plate 1 and a plurality of blades 2 perpendicular to the end face of the circular thin plate 1, wherein each blade 2 extends along a corresponding first arc segment 21, and the first arc segment 21 is arranged from the center of the circular thin plate 1 to the edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com