Large-scale water-lubricating thrust bearing three-section bushing surface

A thrust bearing and water lubrication technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of limited foreign procurement of bearings, and achieve the effects of simple structure, reduced wear of tile surface, and strong manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

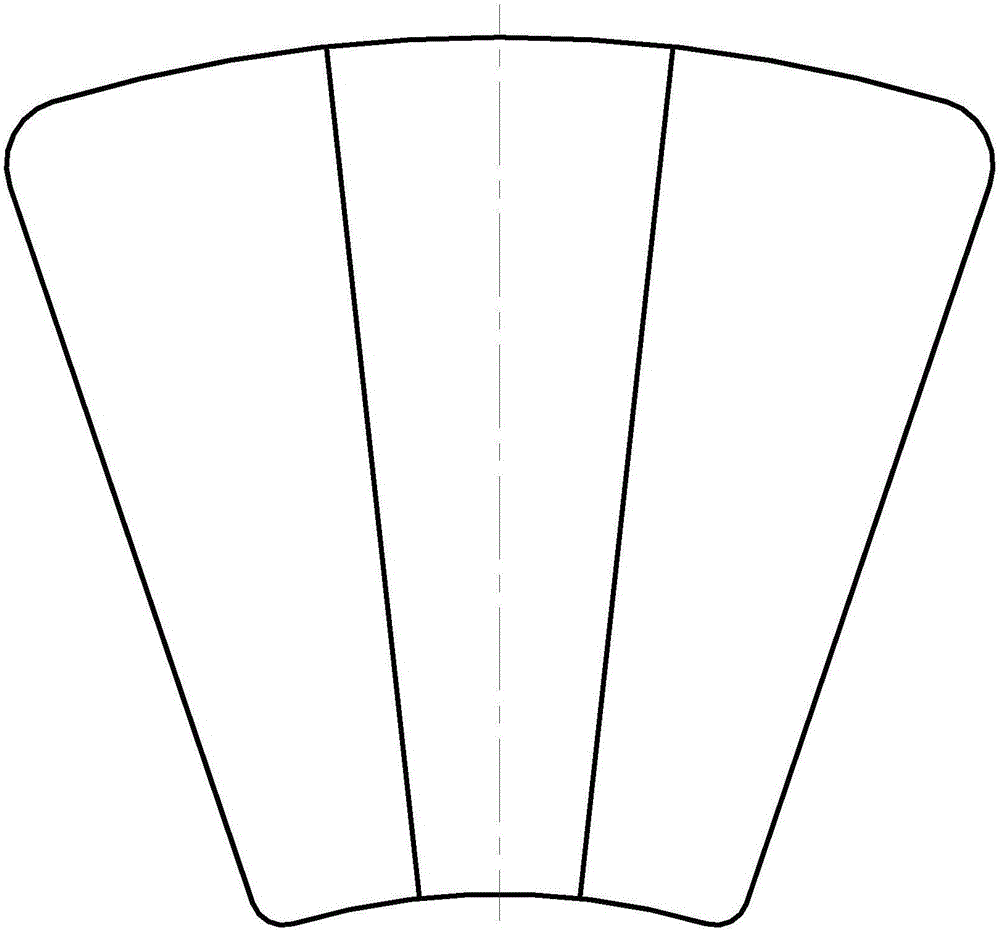

[0016] Such as figure 1 As shown in Fig. 1, a large-scale water-lubricated thrust bearing has a three-section tile surface, and the involved part is a water-lubricated central support thrust bearing for a special motor.

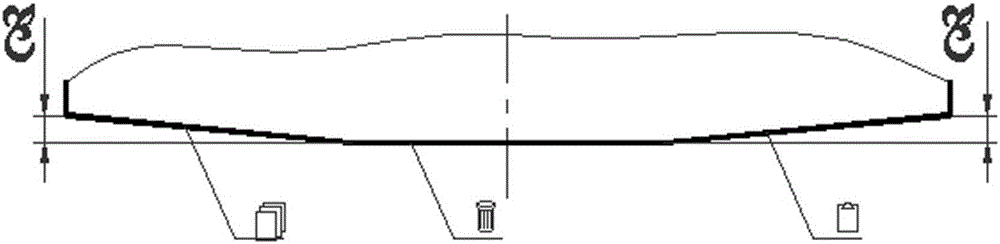

[0017] Such as figure 2 As shown, a large-scale water-lubricated thrust bearing three-section tile surface, the wedge-shaped groove 1 on the water inlet side and the wedge-shaped groove 2 on the water outlet side of the tile surface have the same width, and the wedge-shaped groove 1 on the water inlet side and the wedge-shaped slope on the water outlet side The maximum δ of port 2 is the same. The tile surface 3 and the wedge-shaped groove 1 on the water inlet side and the wedge-shaped groove 2 on the water outlet side are both planes, and the three-section surfaces of the tile surface 3 and the wedge-shaped groove 1 on the water inlet side and the wedge-shaped groove 2 on the water outlet side form a circumferential slightly convex surface, that is, A cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com